New milestones in the construction of the world’s

biggest fusion reactor

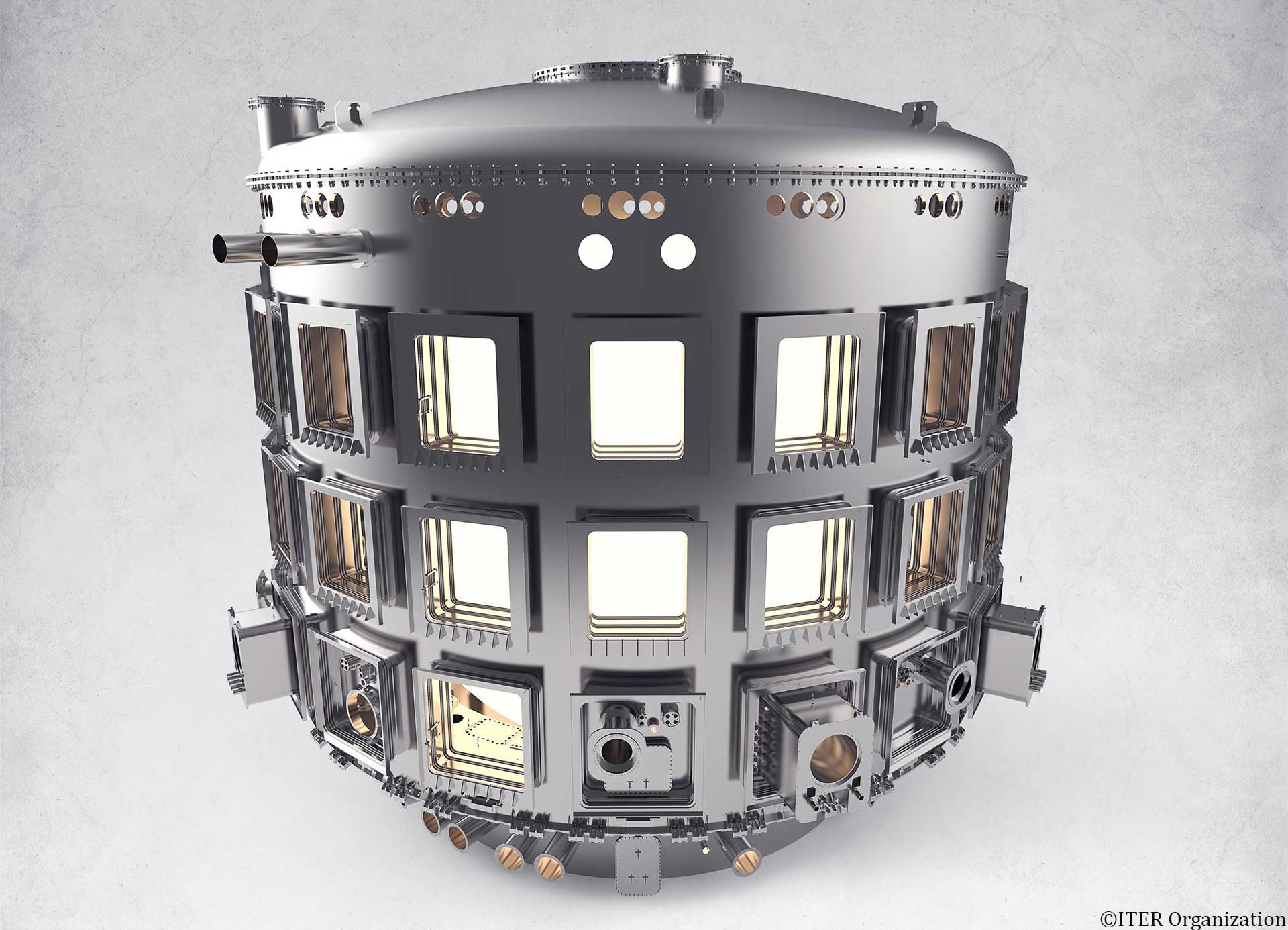

Thirty five nations; more than one million components assembled in factories around the world; over 20€ billion of investment; one of the most complex scientific and engineering projects ever seen: ITER (‘the way’ in Latin) is a project of superlatives. In southern France, a multinational cast of thousands is building the world’s largest tokamak, a magnetic fusion device that could change the future of sustainable energy production. And MAN is playing a major role.

ITER

construction site in Cadarache, Southern France

Using the same principle that powers our sun and stars, ITER aims to fuse atoms in a controlled way that releases almost four million times more energy than burning coal, oil or gas – and four times as much as nuclear-fission reactions. Housing this incredible experiment is a huge, seven-story device weighing 23,000 tons – a so-called ‘tokamak’. Its name is an acronym based on the transliteration of the Russian words describing a ‘toroidal chamber and magnetic coil’.

The fusion reaction occurs when deuterium and tritium are heated to an astonishing 150 million degrees Celsius – ten times hotter than the sun’s core – forming a plasma, a gas-like matter that contains huge amounts of energy. Ultimately, ITER will operate with just three grams of plasma and generate 500 MW of thermal power.

MAN’s ITER contribution

In MAN Energy Solutions’ Deggendorf plant in southeast Germany, MAN specialists are heavily involved in this groundbreaking undertaking. “We currently have contracts for three ITER sub-projects,” says MAN Project Manager Andreas Binni. In 2015, the MAN specialists first arrived at the construction site in southern France to begin the assembly of the cryostat − the largest stainless-steel, high-vacuum chamber ever built – which will form the exterior of the tokamak. When fully assembled, the cryostat will be 30 meters tall with a volume of 16,000 cubic meters.

“We were the first to start work on the tokamak and will be the last to leave the site as we will seal the reactor,” says Binni with pride.

The cryostat – another superlative within a megaproject

The cryostat is a superlative in itself: weighing 3,850 tons, it forms the largest part of the entire reactor. As the outer envelope of the ITER machine, it provides the ultra-cold, vacuous environment necessary for the superconducting coils and vacuum vessel to work.

In total, the cryostat consists of 54 individual elements produced by the Indian company, Larsen & Toubro, which are delivered to the construction site and assembled and welded by a team of up to 40 experts from MAN Deggendorf – a ten-year process in total. The individual components are joined together into four larger components – lower and upper cylinders, a base section, and a top lid – in a pre-assembly hall before they are installed in the tokamak building to form the cryostat.

The cryostat weighing

3,850 tons forms the largest part of the entire reactor.

"The megaproject becomes reality"

MAN specialists have now completed three of the four components, including the gigantic base section that weighs an astonishing 1,350 tons; construction of the fourth and final component of the cryostat – the top lid – is currently underway.

“Five years ago it seemed like an endless road ahead of us, but now the final assembly of the four individual sections that will become the cryostat is scheduled for late-summer 2020. At last, the tokamak is beginning to take shape; it makes me and the team really proud to see this ambitious megaproject becoming reality,” says Binni, who gained a few gray hairs in the process, as he adds with a laugh.

The upper cylinder – part of the gigantic cryostat – is leaving the assembly hall

A MAN welder working on the ITER site in France.

Unprecedented projects call for innovative approaches

The demands of the ITER project have led MAN to develop well-elaborated assembly strategies and enhanced welding techniques, which are now utilized across the company.

“We’re preparing and performing high-precision welds to achieve the stringent tolerances for the out-size components. The required accuracy is on a new level,” explains Binni. “In other words: we are working with the precision of a clocksmith with the only difference being that the components weigh thousands of tons.”

Planning ahead for the energy of the future

As if the technical challenges weren’t enough, the global nature of the project adds an extra hurdle. Thousands of scientists and engineers from the seven ITER members – China, the European Union, India, Japan, Korea, Russia and the United States – have contributed to ITER to date. Each of the seven members is responsible for producing a significant part of the tokamak. “It unites a lot of different countries, cultures and companies, which can make things complex as well as interesting. But everyone is learning and improving as the project progresses,” Binni says.

“Additionally, the number of countries involved, combined with the sheer level of detail and need for the utmost accuracy, make the timelines on this project very long – unlike anything else we have ever worked on,” he adds. “According to current planning, the device won’t be powered-on until 2025, with full experiments starting in 2035.”

The first

major machine component - the cryostat base weighing 1,350 tonnes - is lifted

by a overhead crane and lowered into the Tokamak assembly pit.

A pioneering spirit all across the construction site

When the idea of ITER was first mooted in 1985, it sounded like a bold vision from a science-fiction movie. However, as the reactor building goes up and the tokamak moves closer to its final assembly, the vision of a new, powerful energy-source doesn’t seem quite so fanciful any longer.

“When we arrived at the site in 2015, you felt kind of a tense atmosphere: will this really work?” remembers Binni. “But now there’s this pioneering spirit. We are taking part in the construction of the most complex machine ever built in human history – a project that unites the world community and has the potential to revolutionize energy production. It doesn’t get any bigger than that!”

The timelines on this project [are] unlike anything else we have ever worked on