Enabling a scalable energy transition

The MAN B&W ME-LGIM two-stroke dual-fuel engine can run on methanol as well as conventional fuels. Specifically designed to meet the needs of the maritime industry, it is a versatile and scalable solution that is suited to a wide range of vessel types. Simple handling, storage, and bunkering of methanol, combined with relatively simple auxiliary systems and the potential to be carbon-neutral, makes it an attractive option for meeting decarbonization targets.

Proven two-stroke methanol engine design

Available either for newbuilds or for upgrading existing conventional fuel vessels, this engine represents a proven, refined engine design based on over 600,000 running hours on methanol alone. Methanol produced from renewable sources is an attractive marine fuel option due to its low carbon intensity. An engine using green methanol can even provide carbon-neutral propulsion.

Key benefits

A new design for efficient methanol combustion

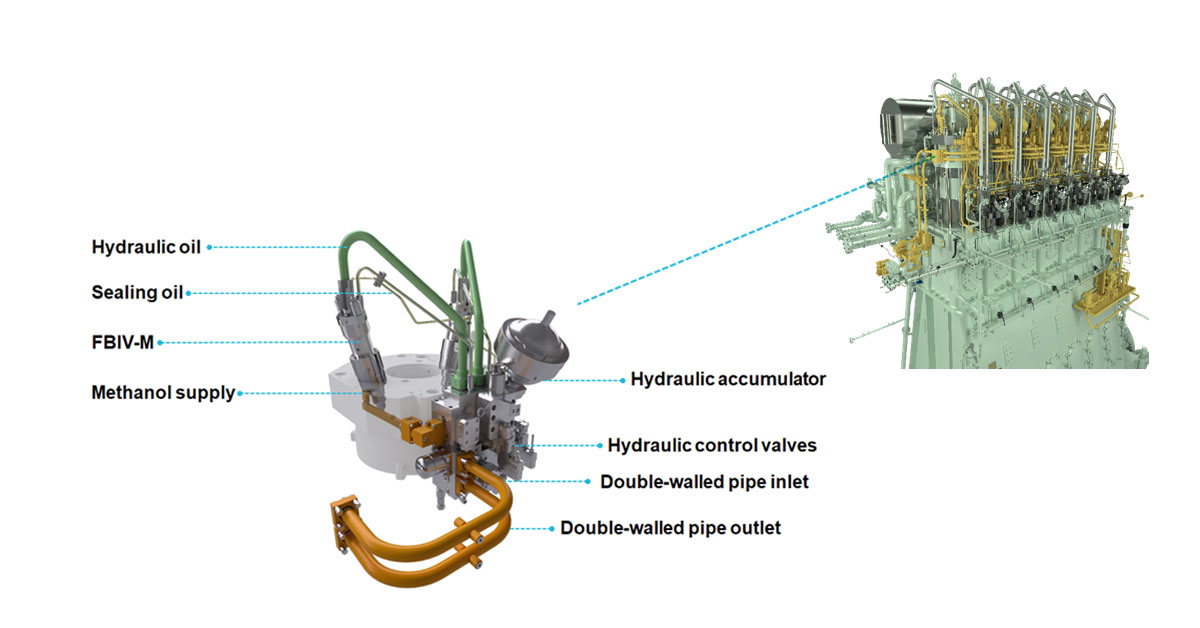

The ME-LGIM engine has inherited well-known components of our standard two-stroke diesel engine, like the ME-GI dual-fuel engine. Beneficial features of the standard MAN B&W two-stroke diesel engine have been retained. This illustration highlights methanol components and pipes that have been added to the cylinder top for methanol combustion.

The use of methanol as fuel type supports cost-effective vessel designs.

Moving together into a sustainable future

Learn more about the MAN B&W ME-LGIM engine

Continue reading

-

MAN B&W ME-LGIMpdf, 504 KB

Related products

Related News

Methanol Engines Continue Rise with Major Order

Hyundai’s shipbuilding division (HHI-SBD) has ordered 6 × MAN B&W G95ME-C10.5-LGIM dual-fuel main engines in connection with the construction of 6 × 17,000 teu container vessels for A.P. Moller – Maersk, the Danish integrated logistics company. Hyundai’s engine machinery division (HHI-EMD) will build the engines in Korea, which will be capable of running on green methanol.

Bjarne Foldager, Senior Vice President and Head of Two-Stroke Business, MAN Energy Solutions, said: “The adoption of methanol propulsion is gaining pace, behind which there are several drivers. Crucially, MAN B&W methanol engines are available and proven with the first engines having already entered service back in 2016. Additionally, as a fuel, methanol can be carbon-neutral when produced from renewable energy sources and bio-genic CO2. The production capacity of such green methanol is currently increasing significantly; it is also liquid at ambient conditions, which simplifies tank design and minimises costs. Finally, our methanol engine only require a fuel-supply pressure of just 13 bar and a number of manufacturers already offer such fuel-supply systems today.”

Thomas S. Hansen, Head of Promotion and Customer Support, MAN Energy Solutions, said: “We currently have a total order book for 78 ME-LGIM engines, of which 24 are firm orders for G95-variants. In addition, 19 of our 50-bore variants are already on the water and have accumulated more than 140,000 running hours on methanol alone. As a fuel, the future looks promising for methanol and we fully expect its uptake to encompass around 30% of all dual-fuel engine orders in just a few years from now.”

About the MAN B&W ME-LGIM engine

MAN Energy Solutions developed the ME-LGIM dual-fuel engine for operation on methanol, as well as conventional fuel. The engine is based on the company’s proven ME-series, with its approximately 5,000 engines in service, and works according to the Diesel principle. When operating on green methanol, the engine offers carbon-neutral transportation of large merchant-marine vessels.

MAN developed the ME-LGI engine in response to interest from the shipping world in operating on alternatives to fuel oil in order to reach decarbonisation targets. Methanol carriers have already operated at sea for many years using the engine, and, as such, the ME-LGIM has a proven track record offering great reliability and high fuel-efficiency.

Projected fuel adoption within two-stroke dual-fuel engines. Today, LNG-fuelled engines make up the vast majority of dual-fuel engine contracting as represented in red in the bar graph above. Interrest in methanol is increasing and a steady uptake to around 30% of all dual-fuel engines contracted is expected by MAN Energy Solutions just a few years from now, as indicated in dark-blue. Towards the end of the decade, ammonia (green) is expected to pick up as a marine fuel

Documents

-

PR Mærsk Container ME-LGIMs_EN

Contact

Nils Søholt

Trade Press Marine

Group Communications & MarktingMAN Energy SolutionsTeglholmsgade 412450 Copenhagen SVDenmark

nils.soeholt@man-es.com t +45 33 85 26 69Available languages

- DE ·

- EN

Get notified about press releases

Alternative fuels for your two-stroke powered vessel: Ammonia, methanol and methane in focus

Register for our next MAN ExpertTalk on alternative fuels for large merchant marine vessels. We will provide insights into the most promising marine fuels of the expected future fuel mix for two-stroke vessels, namely ammonia, methanol and methane.

Further, we will inform about the latest product developments and applications as well as reasons why these fuels have the potential to offer a straightforward path for the future maritime energy transition.

- Wednesday, April 24, 15:00 – 15:45 (W. Europe Standard Time)

- Thursday, April 25, 10:00 – 10:45 (W. Europe Standard Time)