MAN B&W ME-GI prepares your fleet for future regulations

The MAN B&W ME-GI two-stroke dual-fuel engine provides a future-proof solution for LNG/methane-powered vessels thanks to its negligible methane slip and high fuel efficiency.

Based on one of the industry’s most trusted platforms, the MAN B&W ME-GI uses a high-pressure fuel supply system and is suitable for many types of vessels. The engine achieves exceptionally low methane slip emissions and provides a large degree of flexibility for meeting emissions regulations, now and in the future. We have also refined and simplified the design, upgrading key components, and improving reliability.

The world’s most efficient engine for methane as a fuel

Perfect for new builds or retrofits, the MAN B&W ME-GI minimizes operating costs by delivering high industry-leading thermal efficiencies no matter which fuel is used. This is a huge advantage, especially for container vessels in a market with fluctuating fuel prices. The ME-GI can also be fueled with bio-methane as well as synthetic natural gas, providing a clear route towards greenhouse gas reductions.

Next-generation performance and efficiency

Key benefits

- Proven two-stroke MAN B&W engine technology

- Minimal environmental impact (low emissions thanks to negligible methane slip and reduced CO2 emissions)

- No need to compensate with liquid oil fuels to accommodate low methane numbers or high ambient temperatures

- Flexible operation using fuel oil or LNG

- Knocking is not an issue

- Supports waste heat recovery (WHR)

- Easy retrofit compared to Otto cycle engines

Low OPEX

The ME-GI is built for low OPEX, delivering the same industry-leading thermal efficiency no matter which fuel is used. This is a huge advantage in a fluctuating fuel market where LNG bunkering will become the norm. The auxiliary equipment costs have been reduced and the engine’s installation is simplified. Furthermore, key components have been updated to improve performance and deliver a more environmentally friendly solution.

Component upgrades

The new MAN B&W ME-GI incorporates a range of key component upgrades that improve reliability, maximize efficiency and lower OPEX, helping you to stay competitive in a challenging market.

- Lowest gas consumption of any marine two-stroke engine

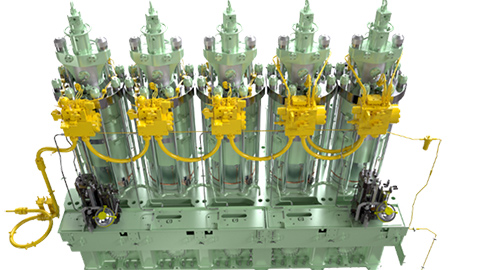

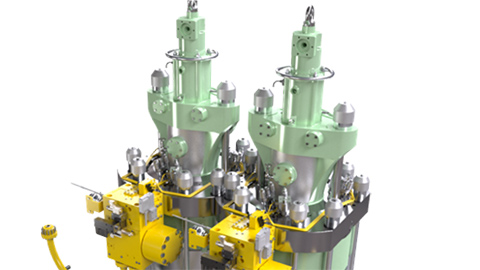

- Simplified piping system provides a more compact solution with fewer components, and therefore lower maintenance costs

- New gas block with an improved window valve enables cut-out of an individual cylinder operating on gas, while allowing continued operation on fuel oil

- Updated pilot oil injection system enables the pilot oil energy fraction be lowered to just 1.5% for certain bore sizes

- Optional compact pump vaporizer unit features embedded redundancy (3 x 50%) and integration with the ME-GI engine control system

Service solutions for optimum cost efficiency of your MAN B&W ME-GI engine

Explore your options for the MAN B&W ME-GI

The new MAN B&W ME-GI two-stroke dual-fuel engine is built to support your power needs today and for the future.

Continue reading

-

ME-GI/GIE pump vaporiser unit for LNG and ethanepdf, 3716 KB

Related products

Related news

ME-GI to Power Ultra-Large Hapag-Lloyd Containerships

MAN Energy Solutions has won an order for 6 × MAN B&W 11G95ME-GI Mk10.5 main engines in connection with the building of 6 × ultra-large, 23,500+-teu container vessels for Hapag-Lloyd, one of the world’s leading liner-shipping companies.

The engines will be built in Korea and will offer the option of operating on LNG or conventional fuel, meeting Tier III emission standards through SCR (Selective Catalytic Reduction). The first engine delivery is scheduled for May 2022. Korean shipyard, Daewoo Shipbuilding & Marine Engineering, will build the vessels with delivery expected from April through December 2023.

In the company’s own press release, Rolf Habben Jansen, CEO of Hapag-Lloyd said: “With the investment in six ultra large container vessels we will not only be able to reduce slot costs and improve our competitiveness on the Europe – Far East trade, but also take a significant step forward in modernizing our fleet. Additionally we will further reduce our environmental impact.”

The newbuildings will be deployed on the Europe – Far East routes as part of THE Alliance and will significantly increase Hapag-Lloyd´s competitiveness in this trade. The engines will operate on LNG, but have sufficient tank capacity to operate alternatively on conventional fuel.

Bjarne Foldager, Senior Vice President and Head of Two-Stroke Business at MAN Energy Solutions, said: “These newbuildings will be fitted with mature ME-GI technology that continues to accumulate references across multiple segments. The engines’ fuel-efficiency and negligible methane-slip tie in perfectly with Hapag-Lloyd’s strategy of sustainability. As we move towards a zero-carbon future, the ME-GI showcases our dual-fuel engine portfolio that is future-proofed to handle whatever alternative fuels come to prominence in the decades ahead.”

The new business follows a series of recent ME-GI sales with 5 × 6G70ME-GI Mk 10.5 dual-fuel engines ordered in October 2020 for 5 × Newcastlemax bulkcarriers for EPS, the Singapore-based shipping company. The previous month, Guangzhou Shipyard International Co., Ltd. (GSI) ordered 2 × 6G60ME-GI Mk 10.5 dual-fuel engines for 2 × LR2 tankers for Hafnia, one of the world’s leading, oil-product tanker owners and operators.

MAN Energy Solutions states that its low-speed, dual-fuel references now exceed 360 units, with the ME-GI recording over 1.5 million operating hours on LNG alone.

The ME-GI engine – the new industrial standard

MAN Energy Solutions successful ME-GI (-Gas Injection) engine has set a new industrial standard for two-stroke propulsion engines aboard – among others – container vessels, bulk carriers, tankers, LNG carriers and car carriers. The ME-GI engine provides ship-owners and operators with a peerless solution within environmentally friendly and high-efficiency, two-stroke technology, without the greenhouse emissions such as methane slip that are characteristic of competing engines.

With the ME-GI engine, two-stroke development has taken a step further by combining the unique properties of multi-fuel combustion and the well-known reliability of MAN Energy Solutions ME-engine. The Diesel principle not only provides the ME-GI engine with high operational stability and efficiency, but also ensures 100% stable and reliable operation during load changes on gas with just normal additions of pilot-oil amounts. Furthermore, the ME-GI operational principles features a seamless change-over between gas operation and diesel operation The ME-GI engine is the most environmentally friendly, technology available within the two-stroke engine segment.

MAN Energy Solutions has also developed an ME-LGI (-Liquid Gas Injection) dual-fuel engine that expands the company’s dual-fuel portfolio, enabling the use of more sustainable fuels such as methanol and liquefied petroleum gas (LPG).

The Maritime Energy Transition

MAN Energy Solutions believes that it is time for what it terms a ‘Maritime Energy Transition’ to find clean, decarbonised solutions for seaborne trade and transportation. Essentially, it is the company’s call to action to reduce emissions and establish natural gases as the fuels of choice in global shipping. It strongly promotes a global ‘turn to gas’, driven by the IMO, and a common approach by the shipping industry and politics to invest in infrastructure development and retrofits.

About Hapag-Lloyd

With a fleet of 234 modern container ships and a total transport capacity of 1.7 million TEU, Hapag-Lloyd is one of the world’s leading liner shipping companies. The company has around 13,200 employees and 388 offices in 129 countries. Hapag-Lloyd has a container capacity of approximately 2.7 million TEU – including one of the largest and most modern fleets of reefer containers. A total of 121 liner services worldwide ensure fast and reliable connections between more than 600 ports on all the continents. Hapag-Lloyd is one of the leading operators in the Transatlantic, Middle East, Latin America and Intra-America trades.

Documents

-

PM_MAN_ES_Hapag-Lloyd_ME-GI_GER

-

PR_MAN_ES_Hapag-Lloyd_ME-GI_ENG

Contact

Nils Søholt

Trade Press Marine

Group Communications & MarktingMAN Energy SolutionsTeglholmsgade 412450 Copenhagen SVDenmark

nils.soeholt@man-es.com t +45 33 85 26 69Available languages

- DE ·

- EN

Get notified about press releases

Alternative fuels for your two-stroke powered vessel: Ammonia, methanol and methane in focus

Register for our next MAN ExpertTalk on alternative fuels for large merchant marine vessels. We will provide insights into the most promising marine fuels of the expected future fuel mix for two-stroke vessels, namely ammonia, methanol and methane.

Further, we will inform about the latest product developments and applications as well as reasons why these fuels have the potential to offer a straightforward path for the future maritime energy transition.

- Wednesday, April 24, 15:00 – 15:45 (W. Europe Standard Time)

- Thursday, April 25, 10:00 – 10:45 (W. Europe Standard Time)