Greenhouse exhaust emissions a main concern for ships

As ships carry passengers and cargo throughout the world, they produce exhaust emissions that have a damaging impact on fragile ecosystems. Finding ways to reduce emissions and make ships greener is an important factor for the future of the marine sector.

Emission regulations becoming even tougher

The shipping industry is responsible for transporting over 95% of all goods traded around the world today. Many ships, like cruise liners and tugs, travel in environmentally sensitive areas. To do so, their engines need to meet very strict emission regulations. IMO Tier III, Emission Control Area (ECA) and Energy Efficiency Design Index (EEDI) regulations define the limits for all vessels sailing in international waters. The global response to the devastating effects of pollution and global warming on marine ecosystems is to adopt even tougher rules for emissions, as seen at the 2015 Paris Climate Conference (COP21).

Keeping hazardous greenhouse emissions to a minimum is a top priority. At the same time, it is also important to not sacrifice ship engine performance and propulsion efficiency. To ensure the future viability of their fleets, ship owners and operators need to do everything they can to minimize the carbon footprint of their vessels. They need to constantly reduce NOx and SOx emissions to stay ahead of ever stricter legislation as it emerges. This means finding and using alternative fuels while utilizing available technologies to operate the cleanest ships possible.

MAN solutions to reduce emissions at sea

MAN Emission Control technologies reduce a ship's emissions through technologies to improve efficiency and utilize cleaner fuels. In this way, we help ships meet all current and future regulations while ensuring a lower impact on the environment.

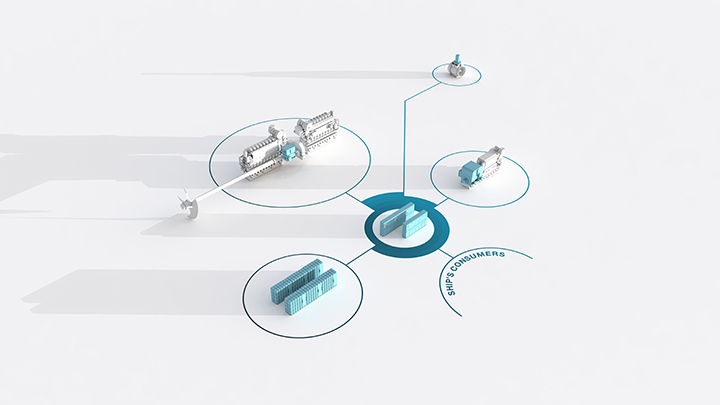

We offer our Emission Control technologies as part of MAN ECO CONTROL, a portfolio of technologies that will help optimize ship performance in terms of emissions, economy and operation. Ship operators benefit from smart processes, efficient operation and predictive maintenance services.

Battery-hybrid solutions

MAN Energy Solutions offers marine battery-hybrid systems, which combine combustion engines with additional batteries to capture and store electric power, optimizing engine operation while reducing emissions. We acquired a 40 percent stake in Aspin Kemp & Associates (AKA), a specialist in the integration of electric propulsion and energy storage systems to enhance our expertise and range of products in this field.

We also offer fully customized hybrid propulsion systems in which mechanical and electric engines work together. These are ideal for vessels with flexible operation profiles and running hours with varying power demands. Our versatile MAN HyProp ECO package combines a CP propeller, diesel engine and electric shaft machine to ensure the highest efficiency and lowest emissions in all operating modes – optimized to meet your vessel’s specific needs.

How you benefit:

- Fewer NOx, SOx and CO2 emissions

- Zero emissions when just batteries are used (especially at slow speeds)

- Increased fuel efficiency

- Quieter operation

- Batteries reduce transient loads, preventing black smoke during maneuvering

- Wide range of operation modes

- Improved performance

Dual Fuel & LNG Gas

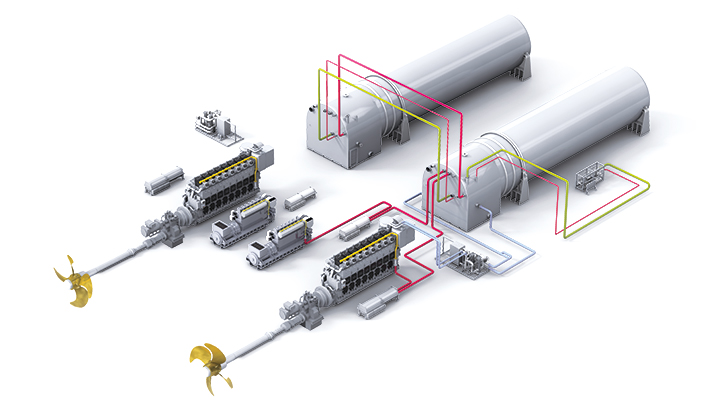

After our 2016 acquisition of Cryo AB, a manufacturer of cryogenic equipment with over 50 years’ experience in cleaner burning Liquefied Natural Gases (LNG), MAN Energy Solutions created the MAN Cryo product brand – the perfect complement to our dual fuel engines. We offer solutions for comprehensive engine and environmentally friendly fuel gas supply systems (FGSS), offshore and onshore bunkering systems, and stationary distribution systems for regasification or fuel filling – all from a single source.

We can tailor our dual fuel propulsion systems to meet every requirement: from LNG technology for dual fuel propulsion to complete LNG handling systems (including carriers, floating storage and regasification units, feeder and bunker vessels).

How you benefit:

- Clean burning gas, fewer NOx emissions

- Increased fuel efficiency

- Lower operating costs

- Dual fuel system means flexibility and fuel independence

- One point of contact for all components, training and support

Exhaust Gas After Treatment

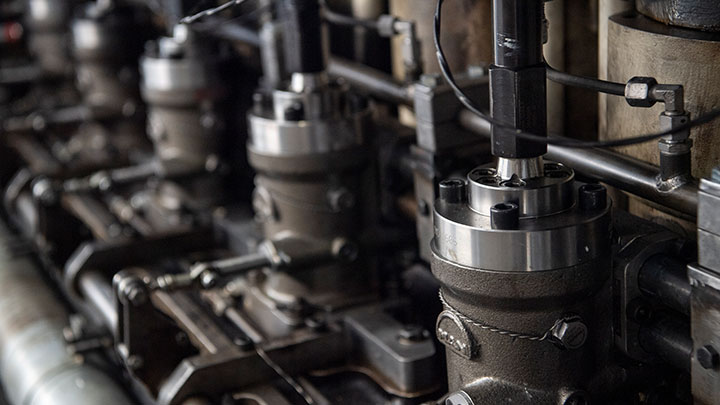

We offer proven exhaust gas after treatment systems that meet the International Maritime Organization’s strict regulations for NOx emissions and fuel sulfur content, even in Emission Control Areas (ECA). Selective catalytic reduction (SCR) and exhaust gas recirculation (EGR) are highly effective technologies to minimize harmful NOx emissions.

Our MAN SCR system is an integrated solution available in 14 different sizes for our entire range of four-stroke medium speed engines. It induces chemical reactions in engine exhaust gases to convert harmful substances into environmentally safe ones. We can also customize MAN SCR systems for new buildings and retrofits upon request.

How you benefit:

- Reduce NOx emissions up to 90%

- IMO Tier III compliance in ECA

- Increased fuel efficiency

- Increased power density

- One source, one point of contact

- Minimum costs, maximum flexibility

A Maritime Energy Transition – Download the new white paper

By 2050, shipping must halve its GHG emissions. Consequently, the Maritime Energy Transition is already underway but the technologies that will power ships in a carbon-neutral future are still under discussion. The paper offers an updated status on potential technologies and outlines the current paths towards a Maritime Energy Transition.

Service solutions for optimum cost-efficiency

MAN PrimeServ offers advanced modernization solutions to optimize the reliability, availability, and economic efficiency of existing equipment. Furthermore, MAN’s modernization and retrofit solutions are tailor-made to customers’ specific applications and machinery.

Reference

World’s first container ship converted to dual fuel

Our Emission Control solutions are designed to meet a wide range of customer requirements and applications while improving their overall environmental impact.

| Customer: | Wessels Reederei GmbH & Co. KG |

| Application: | Retrofit container ship to dual fuel (LNG) |

| Location: | Germany |

| Completion: | August 2017 |

| Fuel: | LNG |

| Commercial Operation: | 07 / 2015 |

| MAN’s Work Scope: | MAN multi-fuel, four-stroke MAN 51/60DF engine, supplied all conversion components |

| Watch video on YouTube |

Forward-looking Emission Control solutions ensure the viability and profitability of the marine industry

- Reduced emissions for an improved greenhouse footprint, meeting all regulations

- Technologies to use alternative and cleaner burning fuels (LNG)

- Increase fuel efficiency for reduced costs

- Improved engine performance and flexibility

Download

-

Cruise and ferrypdf, 6374 KB

-

Exhaust after-treatment systemspdf, 473 KB

-

Four- stroke marine systemspdf, 10891 KB

-

Hybrid marine propulsion systemspdf, 474 KB

-

LNG gas supply and bunker systemspdf, 767 KB

-

MAN EcoLoad advisory toolpdf, 1929 KB

-

MAN L49/60DFpdf, 6253 KB

-

MAN OPL EEXI Overridable Power Limitation MCpdf, 436 KB

-

MAN OPL Enginepdf, 378 KB

-

MAN V49/60DFpdf, 967 KB

Related news

ME-GI to Power Ultra-Large Hapag-Lloyd Containerships

MAN Energy Solutions has won an order for 6 × MAN B&W 11G95ME-GI Mk10.5 main engines in connection with the building of 6 × ultra-large, 23,500+-teu container vessels for Hapag-Lloyd, one of the world’s leading liner-shipping companies.

The engines will be built in Korea and will offer the option of operating on LNG or conventional fuel, meeting Tier III emission standards through SCR (Selective Catalytic Reduction). The first engine delivery is scheduled for May 2022. Korean shipyard, Daewoo Shipbuilding & Marine Engineering, will build the vessels with delivery expected from April through December 2023.

In the company’s own press release, Rolf Habben Jansen, CEO of Hapag-Lloyd said: “With the investment in six ultra large container vessels we will not only be able to reduce slot costs and improve our competitiveness on the Europe – Far East trade, but also take a significant step forward in modernizing our fleet. Additionally we will further reduce our environmental impact.”

The newbuildings will be deployed on the Europe – Far East routes as part of THE Alliance and will significantly increase Hapag-Lloyd´s competitiveness in this trade. The engines will operate on LNG, but have sufficient tank capacity to operate alternatively on conventional fuel.

Bjarne Foldager, Senior Vice President and Head of Two-Stroke Business at MAN Energy Solutions, said: “These newbuildings will be fitted with mature ME-GI technology that continues to accumulate references across multiple segments. The engines’ fuel-efficiency and negligible methane-slip tie in perfectly with Hapag-Lloyd’s strategy of sustainability. As we move towards a zero-carbon future, the ME-GI showcases our dual-fuel engine portfolio that is future-proofed to handle whatever alternative fuels come to prominence in the decades ahead.”

The new business follows a series of recent ME-GI sales with 5 × 6G70ME-GI Mk 10.5 dual-fuel engines ordered in October 2020 for 5 × Newcastlemax bulkcarriers for EPS, the Singapore-based shipping company. The previous month, Guangzhou Shipyard International Co., Ltd. (GSI) ordered 2 × 6G60ME-GI Mk 10.5 dual-fuel engines for 2 × LR2 tankers for Hafnia, one of the world’s leading, oil-product tanker owners and operators.

MAN Energy Solutions states that its low-speed, dual-fuel references now exceed 360 units, with the ME-GI recording over 1.5 million operating hours on LNG alone.

The ME-GI engine – the new industrial standard

MAN Energy Solutions successful ME-GI (-Gas Injection) engine has set a new industrial standard for two-stroke propulsion engines aboard – among others – container vessels, bulk carriers, tankers, LNG carriers and car carriers. The ME-GI engine provides ship-owners and operators with a peerless solution within environmentally friendly and high-efficiency, two-stroke technology, without the greenhouse emissions such as methane slip that are characteristic of competing engines.

With the ME-GI engine, two-stroke development has taken a step further by combining the unique properties of multi-fuel combustion and the well-known reliability of MAN Energy Solutions ME-engine. The Diesel principle not only provides the ME-GI engine with high operational stability and efficiency, but also ensures 100% stable and reliable operation during load changes on gas with just normal additions of pilot-oil amounts. Furthermore, the ME-GI operational principles features a seamless change-over between gas operation and diesel operation The ME-GI engine is the most environmentally friendly, technology available within the two-stroke engine segment.

MAN Energy Solutions has also developed an ME-LGI (-Liquid Gas Injection) dual-fuel engine that expands the company’s dual-fuel portfolio, enabling the use of more sustainable fuels such as methanol and liquefied petroleum gas (LPG).

The Maritime Energy Transition

MAN Energy Solutions believes that it is time for what it terms a ‘Maritime Energy Transition’ to find clean, decarbonised solutions for seaborne trade and transportation. Essentially, it is the company’s call to action to reduce emissions and establish natural gases as the fuels of choice in global shipping. It strongly promotes a global ‘turn to gas’, driven by the IMO, and a common approach by the shipping industry and politics to invest in infrastructure development and retrofits.

About Hapag-Lloyd

With a fleet of 234 modern container ships and a total transport capacity of 1.7 million TEU, Hapag-Lloyd is one of the world’s leading liner shipping companies. The company has around 13,200 employees and 388 offices in 129 countries. Hapag-Lloyd has a container capacity of approximately 2.7 million TEU – including one of the largest and most modern fleets of reefer containers. A total of 121 liner services worldwide ensure fast and reliable connections between more than 600 ports on all the continents. Hapag-Lloyd is one of the leading operators in the Transatlantic, Middle East, Latin America and Intra-America trades.

Documents

-

PM_MAN_ES_Hapag-Lloyd_ME-GI_GER

-

PR_MAN_ES_Hapag-Lloyd_ME-GI_ENG

Contact

Nils Søholt

Trade Press Marine

Group Communications & MarktingMAN Energy SolutionsTeglholmsgade 412450 Copenhagen SVDenmark

nils.soeholt@man-es.com t +45 33 85 26 69Available languages

- DE ·

- EN

Get notified about press releases

Related articles

-

Ammonia engine testing

Engineers are developing a two-stroke, dual-fuel ammonia engine that can reduce a ship’s emissions to zero.

-

Methanol GenSet

Engineers in Denmark are making shipboard power low-emission with the developing of a four-stroke methanol engine.

-

Shipping Decarbonization Study

With revised IMO targets, a new MAN Energy Solutions’ study looks at the best technological and financial options to decarbonize maritime transportation

-

Upgrading your fleet for future fuels

MAN Energy Solutions experts on the climate impact and business case for converting ships to dual-fuel engine operation.

-

Buildung a hydrogen engine

MAN Energy Solutions expert Matthias Auer on developing hydrogen-capable, gas-fired engines for power plants.

-

shipping-emission-overshoot

Shipping is annually making large withdrawals on the carbon budget – so large they probably cannot be caught up.

-

The route to climate-neutral shipping

Volker Quaschning, Johannah Christensen and Christopher Hebling address solutions to decarbonize maritime shipping with e-Fuels.

-

Making the maritime energy transition

The work being done on carbon-neutral engines at the Research Centre Copenhagen in Denmark is crucial for the maritime energy transition.

-

The benefits of methanol

What makes methanol so attractive for the maritime energy transition? MAN Energy Solutions fuel expert Kjeld Aabo explains.

-

Designing the engines of the future

The time is ripe for the sustainable engine solutions of the future. Here’s how MAN engineers are developing engines running on green fuels.

-

LPG makes waves in green shipping

Pontus Berg of BW LPG talks about retrofitting vessels with greener dual-fuel LPG engines.

-

The cost of zero-emission shipping?

Global Maritime Forum’s Johannah Christensen on e-fuels, Covid-19 and a trillion dollar investment.

-

What the future holds for shipping

Can shipping halve emissions by 2050? We look at four scenarios with four very different outcomes.

-

Green ammonia production

MAN Energy Solutions is developing a fuel-flexible, two-stroke ammonia engine as a key technology in the maritime energy transition

-

The case for two-stroke ammonia engines

Why newbuild and retrofit ammonia engines are key for the maritime energy transition.

-

FROZEN – The world of cryogenic fuels

Meet the Swedish cryogenic-fuel experts that are having fun greenifying shipping

-

Climate change strategy for shipping

What ship owners, builders and regulatory agencies can do to cut emissions in shipping by 50 percent.

-

When cars cross oceans

200 meters long and 13 car decks high these new mammoth car carriers run on LNG.

-

Climate-friendly engines go fishing

The first LNG-powered fishing trawler nets industry attention for its big emission reductions.

-

Setting sail for a sustainable future

The IMO sets targets for decarbonization. Here’s how marine shipping can help achieve climate goals.

-

A roadmap to the green zone

The first container ship converted to LNG offers real insight into making the industry carbon-neutral.