Leveraging key technologies to achieve sustainability

We have always considered challenges within the larger context. Today, this means acknowledging that no one single solution or technology can get us towards our goal of net zero emissions. This is why we have selected and developed five key technologies which make up the center pillars of our decarbonization strategy, complementing our existing and always evolving core portfolio.

These technologies are able to reduce emissions in hard-to-abate sectors such as shipping, power and heat generation, industrial processes such as cement and chemicals, which are energy-intensive and hard to electrify. Green engines, solutions for carbon capture, utilization and storage (CCUS), as well as innovative industrial-scale heat pumps, cost-effective electrolyzers for green hydrogen production and retrofitting solutions – all of these technologies give us the leverage to decarbonize industries as quickly as possible.

Our five core technologies have immense leverage to reduce CO2 emissions. With these alone, we can address up to 10% of global CO2 emissions.

Key transitional technologies

The following figures are examples of the benefits of MAN Energy Solutions’ solutions

5 key future technologies

We offer a portfolio of pioneering future technologies that help fight climate change while presenting significant market potential and business success. With our know-how, expertise and leading edge in each of these technologies, we are well-equipped to provide sustainable solutions to the current climate challenges.

We retrofit ships and plants to reduce fuel consumption and emissions.

Our green engines powered by future fuels such as green hydrogen, ammonia, methanol, and biofuels, are essential for long-term decarbonization.

We are also working with partners on CCUS (carbon capture, utilization, and storage) to capture and store unavoidable carbon dioxide emissions.

Lastly, our heat pumps are an energy-efficient solution for heating and cooling buildings by reducing energy demands.

Related news

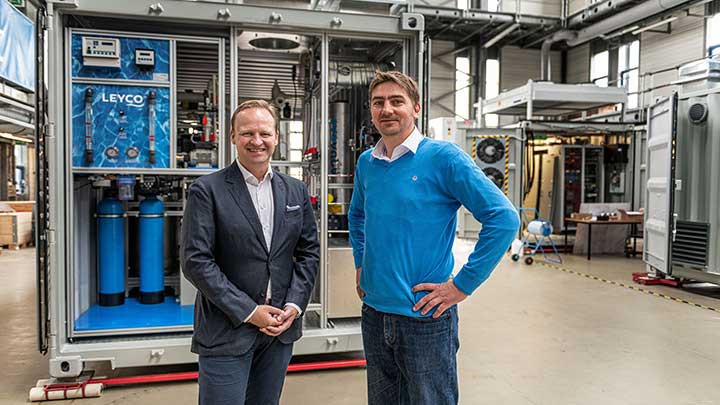

H-TEC SYSTEMS Establishes Manufacturing Facility for PEM Electrolysis Stacks to Produce Green Hydrogen

Attended by representatives from the local political and business communities, hydrogen specialist H-TEC SYSTEMS – a subsidiary of MAN Energy Solutions – has held the groundbreaking ceremony for its new production facility in Hamburg.

The H-TEC SYSTEMS Stack Manufacturing & Development Center will gather stack development, production and testing in one location, employing several hundred employees in the long term. As early as 2024, the new location will automate the production of PEM electrolysis stacks with a potential total electrolysis capacity of 5 gigawatts. The stacks will form the core of the PEM electrolysers, which are built at the company's headquarters in Augsburg.

Dr. Uwe Lauber, CEO of MAN Energy Solutions, said: “For a successful hydrogen ramp-up, we need to scale up from individual stack manufacture to automated series production, which is why we are breaking ground here today; I am very pleased that H-TEC SYSTEMS is at the forefront of this development. MAN Energy Solutions is investing 500 million euro into electrolyser manufacturing over the next few years to make H-TEC SYSTEMS one of the world's top three manufacturers.”

Hydrogen demand

Through the new site in Hamburg, H-TEC SYSTEMS is strengthening its position in the hydrogen market and making a decisive contribution to the global hydrogen ramp-up.

Robin von Plettenberg, CEO of H-TEC SYSTEMS, said: “The demand for industrial hydrogen solutions is continuously growing. With over 11,000 square metres of space for production and testing here, we are ideally positioned to cover future product generations in our new location and thus enable the global hydrogen ramp-up. For a smooth, highly available and cost-effective production of PEM electrolysers and stacks, it is also necessary – in addition to automated production – to align the relevant supply chains with the needs of electrolyser and electrolysis stack production.”

The construction of the automated factory is part of the PEP.IN research project, funded by the German Federal Ministry of Education and Research (BMBF) through the flagship hydrogen project, H2Giga. The project aims to research novel processes for the competitive and mass production of PEM electrolysis stacks and electrolysers in order to make green hydrogen affordable and competitive. In addition to the proven S450 stacks, H-TEC SYSTEMS will also develop and produce a new, higher-performance generation of stacks in its Stack Manufacturing & Development Center.

H-TEC SYSTEMS states that it made a conscious decision in favour of the new location in Hamburg as a sign of its clear commitment to Germany as a production location. Furthermore, its supply chains for stack production are also based predominantly on German and European suppliers.

Documents

-

MAN ES_PR_H-TEC-groundbreaking_ENG

Contact

Jan Hoppe

Head of Group Communication & Marketing

Group Communications & MarketingMAN Energy Solutions SEStadtbachstr. 186153 AugsburgGermany

Jan.Hoppe@man-es.com t +49 821 322 3126Available languages

- DE ·

- EN

Get notified about press releases

Related articles

-

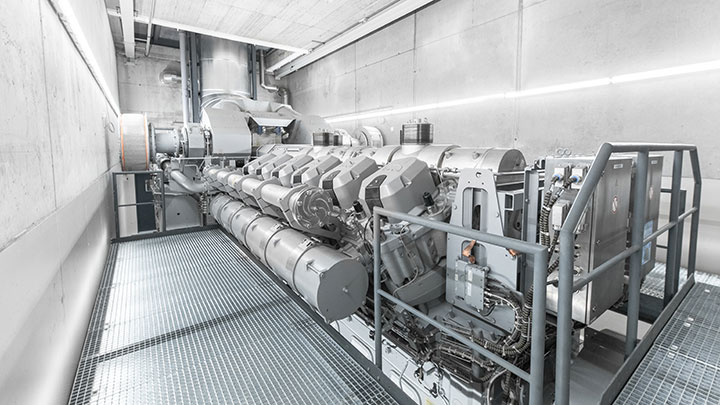

Gas engine power plant in Chemnitz

Find out how two gas engine power plants in Chemnitz, Germany, are cutting CO2 emissions by 60 percent and paving the path for a carbon-free future.

-

Methanol fueled ships

Sustainable shipping starts now. Find out more about the first large-scale engines for container ships run on green methanol.

-

Haru Oni e-fuels

The Haru Oni demonstration plant could pave the way for a viable alternative to fossil fuels: It produces synthetic e-fuels from hydrogen that can help the fight against climate change. MAN Energy Solutions provided the e-methanol reactor to the plant.

-

Esbjerg Heat Pump

How a seaport town in Denmark is decarbonizing district heating with seawater and large-scale industrial heat pumps.

-

Upgrading your fleet for future fuels

MAN Energy Solutions experts on the climate impact and business case for converting ships to dual-fuel engine operation.

-

H-TEC SYSTEMS: The hydrogen electrolyzer pioneer

Under new leadership, PEM electrolysis pioneer H-TEC SYSTEMS is scaling up electrolyzer production to meet the growing demand for green hydrogen.

-

bellona-carbon-capture-storage

Carbon Capture and Storage is one of the necessary building blocks to achieve carbon-neutral industry, says Erika Bellmann of NGO Bellona.

-

ETES heat pump

Danish utility DIN Forsyning is using an innovative solution with new ETES heat pump technology to decarbonize heating for an entire town.

-

Carbon capture utilization storage

Carbon capture, utilization and storage will become more important for the energy transition as unavoidable emissions move to the forefront of discussions.

-

Making the maritime energy transition

The work being done on carbon-neutral engines at the Research Centre Copenhagen in Denmark is crucial for the maritime energy transition.

-

The benefits of methanol

What makes methanol so attractive for the maritime energy transition? MAN Energy Solutions fuel expert Kjeld Aabo explains.

-

Designing the engines of the future

The time is ripe for the sustainable engine solutions of the future. Here’s how MAN engineers are developing engines running on green fuels.

-

Combined Heat and Power systems for the future

How combined heat and power plants support a German city to reach its target of climate-neutral power and heat generation until 2035.

-

Heating up renewable energy storage

Energy-expert Professor Manfred Wirsum on decarbonizing how we heat and cool the places where we live and work.

-

The art of sustainable production

Behind the practices making climate protection a fundamental part of our manufacturing.

-

LPG makes waves in green shipping

Pontus Berg of BW LPG talks about retrofitting vessels with greener dual-fuel LPG engines.

-

What the future holds for shipping

Can shipping halve emissions by 2050? We look at four scenarios with four very different outcomes.

-

The case for two-stroke ammonia engines

Why newbuild and retrofit ammonia engines are key for the maritime energy transition.

-

The art of green hydrogen

For decades this company has been perfecting the tech that turns renewables into green hydrogen.

-

When cars cross oceans

200 meters long and 13 car decks high these new mammoth car carriers run on LNG.

-

Shining a light on a smart island

How the remote Faroe Islands are using a microgrid to become 100 percent green in the next decade.

-

Making fuel from sunlight and air

This mini-refinery above the rooftops in Zurich captures carbon and solar power to create clean fuel.

-

Climate-friendly engines go fishing

The first LNG-powered fishing trawler nets industry attention for its big emission reductions.

-

Cleaner energy for Rock of Gibraltar

When Gibraltar upgraded its nearly 40-year-old power system, they opted for a unique LNG solution.

-

Designs for a livable future

Giant kites and smog-sucking towers: Can socially-oriented designs create a more sustainable world?

-

Automated subsea platform for deepwater compression

The world’s first subsea compression system has revolutionized oil exploration; learn how automation and digitalization make it cleaner and more efficient.

-

Energy transition – concrete steps to combat climate change

Which future fuel solutions do we need to reach our climate goals? VDMA expert Matthias Zelinger on solutions towards global decarbonization.

-

Innovation inspired by nature

By learning from and emulating nature’s solutions, biomimicry can help solve complex human design and engineering problems.

-

Combined Heat and Power

A new combined heat and power (CHP) plant delivers a flexible and efficient energy solution that saves up to 60,000 metric tons of CO2 per year.

-

Power-to-X

Power-to-X is the carbon-neutral energy storage and sector coupling technology of the future: Our actions within this decade will decide whether we are able to reach the ambitious goals of the Paris agreement.

-

-

Setting sail for a sustainable future

The IMO sets targets for decarbonization. Here’s how marine shipping can help achieve climate goals.

-

A tale of fire and ice

Inside the electro-thermal energy storage solution that will green the heating and cooling sector.

-

World’s largest fusion reactor

In southern France, a cast of thousands is working to change the future of sustainable energy.

-

A roadmap to the green zone

The first container ship converted to LNG offers real insight into making the industry carbon-neutral.