Carbon capture, utilization and storage traps emissions before they even enter the air. Here’s how it works.

Reducing emissions isn’t enough. As unavoidable emissions move to the forefront of discussions, scientists, politicians and industry leaders agree — there is no way to achieve climate targets without carbon capture. Here’s how the technology works and what is still needed to bring it out of the lab and into the real world.

By Oliver Sachgau

How to deal with unavoidable emissions has been a central question in the race to achieve climate goals. Certain industries such as concrete and cement simply have no alternative to their methods. In fact, cement production alone, which emits large amounts of carbon dioxide (CO2) into the atmosphere from the chemical reaction that turns limestone into cement, is responsible for 8 percent of all CO2 emissions – four times the amount of Germany.

This means innovative new approaches are urgently needed – chief among them: carbon capture, utilization and storage, or CCUS, which can trap and use the CO2 released from fuel combustion or industrial activities.

Around 30 percent of global CO2 emissions are considered unavoidable

In the past, CCUS has struggled to gain acceptance, especially in Germany, with critics at the time arguing it would be better to finance proven technologies like renewables. Nevertheless, some European countries have implemented largescale projects, and today, policymakers and industry leaders are calling for an international strategy that will make CCUS financially feasible and create a circular carbon economy.

“Around 30 percent of global CO2 emissions are considered unavoidable’,” says Uwe Lauber, Chief Executive Officer of MAN Energy Solutions, which has longstanding experience in decarbonization, carbon capture and industry support. "For numerous industries in this 'hard to abate' sector, CCUS technologies are the indispensable prerequisite for successfully working toward the global 'net zero' goal.”

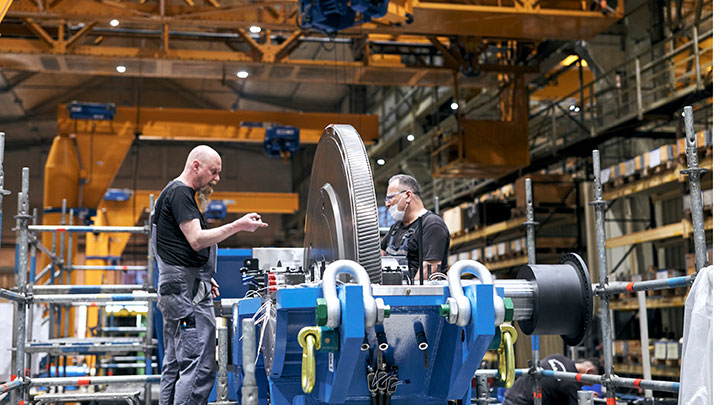

The compressors made at MAN Energy Solutions’ Berlin factory allow carbon to be stored in depleted oil fields or saline aquifers. The compressed carbon can also be transformed into other useful products, including green methane. ©Stefan Hobmaier

How carbon capture works

CCUS starts with carbon capture, removing emissions directly from the air or, more usually, before they’re released into the atmosphere in the first place. The captured gas is then compressed as a liquid or solid and either stored deep underground or made available for further processing. For example, the captured carbon can be combined with green hydrogen to create climate-neutral methane fuel or methanol, or it can be transported to industries that need it to produce everything from plastics to fertilizer. “Right now CO2 is still only seen as a greenhouse gas,” adds Lauber, “but we shouldn’t ignore the fact that carbon dioxide plays an important role as a feedstock for the production of cleaner future fuels.”

Capturing carbon can be done in a few different ways, either before or after combustion or by using oxyfuel, which involves burning fuel using pure oxygen. Or, as already mentioned, it can also be removed from the air after it’s been emitted

by using a technology called direct air capture (DAC). However, with only 16 plants currently in operation worldwide, development on DAC technology is still in its early days, and the large amount of energy required to separate CO2 from ambient air

makes it more costly.

Capturing CO2 directly from industrial exhaust gases is right now the more promising approach, and from a technological point of view, CCUS is already feasible. Capture technologies have been around for years, and MAN Energy Solutions makes the compressors needed to turn carbon into a liquid at their factory in Berlin. Moreover, there are also largescale projects underway that prove the technology works, including 76 in North America and 38 in Europe, mainly in the United Kingdom, Netherlands and Norway.

Cement industry’s first largescale plant with CCUS

In Norway, for example, HeidelbergCement is constructing the cement industry’s first largescale plant with CCUS, which will begin operations in 2024. Around half of the plant’s carbon emissions will be captured – some 400,000 tonnes annually. The compressed carbon will then be transported by ship and injected into depleted gas reservoirs under the North Sea for storage underground.

In Brevik, Norway, HeidelbergCement will realize the world's first carbon capture facility for largescale cement production starting in 2024, with 400,000 tons of CO2 to be captured annually from the factory. ©MAN Energy Solutions

An early adopter of CCUS, Norway quickly recognized that some industries have unavoidable emissions, says Torgeir Larsen, the Norwegian ambassador to Germany. “We’re entering a new era. We need steel, we need cement. We have to find a way to capture that CO2.”

Energy security and CCUS

In Germany, CCUS still faces an uphill battle. Over a decade ago, the country debated whether the technology could be used to reduce emissions from coal-fired power plants or would it allow the coal industry to slow or even avoid the move to renewable energy altogether.

We’re entering a new era. We need steel, we need cement. We have to find a way to capture that CO2.

Fifteen years later, says Gilles Le Van, Vice President of Large Industries and Energy Transition for Central Europe at Air Liquide, we’re living in a completely different reality. “We weren’t on a path of transformation back then. We weren’t as advanced in our conversations about complete decarbonization.”

That new reality, according to MAN Energy Solutions CEO Uwe Lauber, also includes recent events that have pushed energy independence and a path toward a unified European energy policy into the foreground. “The current situation in Ukraine has made it exceedingly clear that we need to rebuild our energy systems to become less dependent on fossil fuels – and quickly,” says Lauber. “This includes renewable energy and green hydrogen, but also carbon capture, utilization and storage, which allows us to reduce emissions and leverage CO2 as an important feedstock for climate-neutral fuels.”

As a result, German politicians are now increasingly viewing CCUS as a vital part of the energy transition and appear set to reevaluate the country’s current carbon capture and storage law. The Minister for Education and Research Bettina Stark-Watzinger

says that if Germany wants to meet its goal of becoming climate-neutral by 2045, it will need to do so with carbon capture. “Our guiding principle is innovation not austerity, and anyone who takes this notion seriously will see the necessity

of CCUS.”

Because Germany has taken longer than some European countries to adopt CCUS, it is still missing the regulatory framework. “We need to get into gear so that other countries don’t eclipse us,” says Gilles Le Van, who also chairs the German Association of Industrial Energy and Power Industries (VIK). ©Stefan Hobmaier

The right regulatory framework is crucial for climate goals, says Erika Bellmann, Head of Germany Programs at the Bellona Foundation in Berlin, where the organization focuses on climate protection in industry. ©Stefan Hobmaier

Robin Mesarosch, a member of the Social Democratic Party in the German Bundestag, agrees: “We urgently need CCUS to reach our climate goals,” he says and adds that there are both environmental and economic benefits for Germany. “The technology being developed here will be needed all over the world and will allow our own industries to still be able to produce their products in a future that’s carbon neutral.”

The goal of a circular carbon economy

To avoid a repetition of the last decade, a global CO2 strategy is needed, starting with legislation in Europe that allows for cross-border capture, transport and storage, according to experts in industry and politics.

The strategy starts with a global carbon price, says Erika Bellmann, Head of Germany Programs at the Bellona Foundation, an independent nonprofit organization that fights climate change by identifiying and putting sustainable environment solutions into practice. If implemented, and high enough, a carbon price will provide an incentive for capital-intensive industries to implement CCUS in their plants.

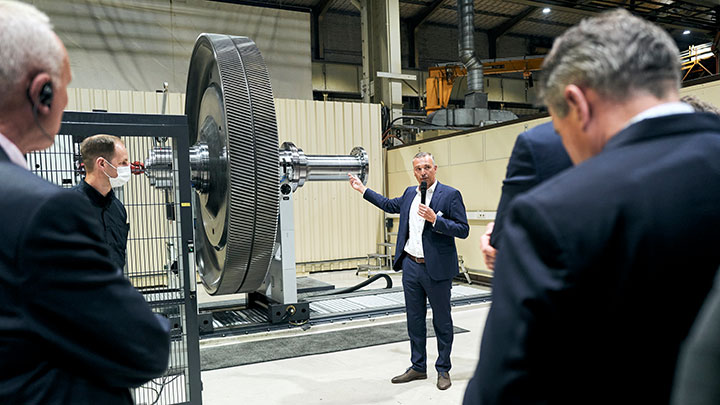

Markus Röhner, site manager at MAN Energy Solutions in Berlin, is giving insights into MAN Energy Solutions’ compressor production in Berlin – a key technology for CCUS projects worldwide. ©Stefan Hobmaier

Beyond that, adds Le Van, a more comprehensive regulatory framework is still needed in Europe. The economic area still restricts how and where carbon can be transported. “Right now, we can’t transport across borders, and we don’t even have legislation to store in Germany. We need to get into gear so that other countries don’t eclipse us.”

“The companies and the technologies are ready to go,” says Bellmann. “Now, if we can get the regulatory framework in place, it would encourage a substantial and quick contribution to climate protection.”

The aim would be to create a carbon circular economy. Carbon would be captured in one country, transported by pipeline, rail or freight to another, and then turned into a usable product before being transported again, only this time as a fuel. This circular economy is key especially if Europe wants to ramp up its hydrogen production, says Lauber, adding that “to cover one percent of the annual fuel demand in the shipping industry with synthetic natural gas we’ll need around one million tonnes of hydrogen and seven million tonnes of CO2.”

The use of carbon removal is “unavoidable”

The faster CCUS gains mainstream attention now, the sooner companies will be able to build largescale carbon capture projects. Over and above that, the amount of emission reductions in different sectors will eventually show how much direct air capture and other activities that remove CO2 from the atmosphere will truly be needed.

An April 2022 report from the United Nations’ Intergovernmental Panel on Climate Change (IPCC) states that the use of such measures “to counterbalance hard-to-abate residual emissions is unavoidable if net zero CO2 or GHG emissions are to be achieved." Experts estimate that around four gigatonnes of CO2 will need to be captured by CCUS to reach climate goals – 100 times more capacity than today.

Uwe Lauber puts it boldly: “It isn’t enough to talk about CCUS. We need to stop doing lab projects, and start doing real projects.”

The future of carbon

About the author

Oliver Sachgau is a Berlin-based German-Canadian writer and journalist, focused on financial topics. His work has appeared in Bloomberg, The Washington Post, Fortune and The Independent.

Explore more topics

-

The latest-generation wind turbine installation vessel

A new wind turbine installation vessel with a customized-engine configuration lets offshore wind contractor Cadeler transport and lift more powerful turbines in even rougher locations – and they’re saving emissions while they are at it.

-

Hapag Lloyd LNG container vessel

Hapag-Lloyd’s new LNG-powered containership cuts emissions by a quarter immediately and by 95 percent with green methane

-

Heidelberg Materials: First CCS plant for cement industry

The first CCS facility for cement production in Brevik, Norway, is paving the way for carbon-neutral industrial processes.

MAN Energy Solutions is now Everllence.

We have adopted a new brand name and moved to a new domain: www.everllence.com. This page will also be relocated there shortly. We are working on shifting all pages to www.everllence.com.