Future proof engines for offshore wind vessels

More wind farms, bigger turbines, rougher locations: demand for renewable energy is stimulating growth in construction of wind parks at sea. Environmental responsibility demands that we minimize the carbon footprint associated with both installation and operation. The answer is a new class of wind farm installation vessels with clean, efficient engines that can cope with complex tasks in harsh conditions. We have drawn on our extensive experience in the offshore sector and we have future-proofed our engines for green fuels. Here you will find engines you can build on.

Wind, waves, and clean energy

The vessels that transport, install, and maintain wind turbines must live up to high environmental standards. To meet the goal of carbon neutrality, vessels need reliable engines that are clean and highly efficient: operators’ reputations depend on them. As the wind farms migrate further offshore in search of strong winds, the sea conditions become tougher.

Offshore wind engine portfolio

The methanol-ready MAN 32/44CR and MAN 175D engines are reliable, efficient, low-emission designs. These engines are perfectly suited for specialist wind farm applications such as wind turbine installation vessels (WTIVs) and wind foundation installation vessels (WFIVs) or for general offshore support vessel applications such as service operations vessels (SOV) and commissioning service operation vessels (CSOVs).

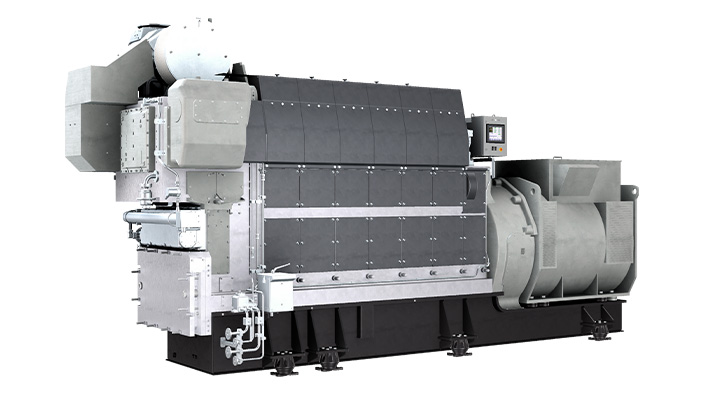

Methanol-ready MAN 32/44CR

The MAN 32/44CR brings together the most advanced large-engine technologies, including the MAN common rail system, high-efficiency turbochargers, variable valve timing and state-of-the-art control systems. These advantages are future-proofed by the availability of the methanol retrofit.

Available as propulsion engine or GenSet.

Methanol-ready MAN 175D

The most powerful high-speed engine on the market meets emissions standards without compromising on efficiency or performance. Thanks to its compact size and clear-cut design, it is easy to integrate and easy to operate and maintain. Long TBOs and low fuel consumption ensures the lowest OPEX and reduces emissions. A methanol dual fuel retrofit will be available from 2026.

MAN 175D GenSet

Packing the latest technology into minimal space, the MAN 175D GenSet is characterized by a clear-cut design, flexible ship integration, simple operation, and straightforward maintenance. Its modular design allows it to meet all the challenges of today’s offshore applications.

MAN L21/31 Mk2

MAN L21/31 Mk2 offers reliable power,

stable operation and the possibility to operate this engine on conventional

fuels as well as biofuel oils. Optimized engine design with improved fuel

efficiency delivers cost efficiency during its entire life cycle. This engine

represents a safe investment for your offshore wind vessel.

Methanol-fuelled MAN L21/31DF-M

Methanol-fuelled MAN L21/31DF-M is a compact and reliable engine which offers fuel flexibility and possibility to lower greenhouse gas emissions. It can be operated on methanol, conventional fuels as well as most biofuel oils. With its outstanding load-step capabilities and extremely long time between overhauls (TBOs), it is a perfect future-proof solution suitable for powering your offshore wind vessel.

MAN L27/38 Mk2

Powerful MAN L27/38 Mk2 delivers improved competitiveness and reliable operation which make it a solution suitable for most offshore applications. This engine can run on conventional fuel types as well as biofuel oils and offers cost efficiency during its entire life span. The methanol version of this engine (MAN L27/38DF-M) is already in development.

MAN ExpertTalks

-

Energy & Storage

From source to solution: Methanol’s missing link in energy transition

MAN ExpertTalkE-methanol is produced using renewable energy. This often comes from offshore wind turbines, which are installed by specialized vessels, which are powered by MAN methanol engines. These are just some of the links in the methanol value chain, but they show how MAN Energy Solutions can bring together suppliers and consumers of methanol. We also provide links through CCS, hydrogen electrolysis, and methanol synthesis.

References

Unique Engine Concept to Power Cadeler’s Hybrid Foundation/Wind Turbine Installation Vessels

MAN Energy Solutions has won a fourth order to supply engines to Chinese shipbuilder, COSCO Heavy Industries, in Qidong for the construction of a second F-Class installation vessel used for the installation of offshore wind turbines and foundations. The previous three orders were for engines for two X-class and another F-class vessel. All four vessels are bound for Danish service provider, Cadeler, which specialises in offshore wind transportation, installation, operation and maintenance as well as decommissioning. The four vessels are scheduled for delivery from 2024 through 2026.

X-class vessels are designed to operate at some of the most difficult sites around the globe with a deck space of 5,600 m2, a payload of over 17,600 tons and main crane capacity >2,000 tons at 53 metres. The F-class has similar specifications but is uniquely flexible and can be quickly converted from a foundation-installation unit to a wind-turbine-generator installation vessel.

Cadeler’s CEO, Mikkel Gleerup, said: ”We are currently building four unique, pure-play, offshore vessels that aim at installing the foundations and wind turbines of the future. In order for our vessels to optimally operate, we need engines that meet our requirements by delivering the needed lifting capacity. Our cooperation with MAN has been a good and steady one throughout the years. We chose them as supplier as they have demonstrated the ability to deliver a product that is innovative and of high standard, which will be a good fit with the rest of the vessels’ capabilities.”

Each vessel will feature an engine configuration based on a mixed MAN medium- and high-speed engine concept with 2 × 6L32/44CR + 2 × 9L32/44CR + 2 × 12V175D engines. As a result, the newbuildings will have the greatest lifting capacity of any vessel ever seen in the field in line with the growing size of modern wind turbines. Each engine will also feature SCR (Selective Catalytic Reduction) and meet IMO Tier III emission standards.

Elvis Ettenhofer, Head of Marine Four-Stroke APAC, MAN Energy Solutions, said: “This is a unique application that will set a new standard for offshore turbine installation and sustainable marine operations, as well as being a great showcase for our mixed-engine concept. With its reliability and long times between overhauls, the 175D has the DNA of a medium-speed engine, which is why it matches so well with our 32/44 units. Only MAN can provide this unique engine-configuration with the highest efficiency, lower weight and a greater payload; this represents real value for our customer, Cadeler.”

The F-class jack-ups will be able to transport and install seven complete 15MW turbine sets per load or six sets of 2XL monopile foundations per round-trip – a substantial improvement in efficiency over existing vessels. The vessels will also feature a unique design that enables their conversion from foundation-installation to wind-turbine-installation vessels (WTIVs).

MAN medium and high-speed engine concept

This concept involves frameless 2 × MAN 6L32/44CR + 2 × MAN 9L32/44CR + 2 × MAN 12V175D engines and offers a number of advantages:

- space savings – including small total genset footprint and compact SCR sizes – minimises engine room and funnel space, leading to larger deck area;

- optimised power/weight ratio with the mixed engine concept including the frameless design for the medium-speed 32/44CR engines. In this instance, the total engine weight of the Cadeler project is around 200 tonnes. This is a new benchmark that saves fuel, CO2 emissions and increases the payload

- optimised OPEX through low SFOC during low-load operation and off-engine when not required. This delivers an efficient fuel consumption and reduced engine-operating hours

- increased redundancy – the 32/44CR and 175D lead in engine dynamics and load ramp-up. Hence, it is possible to have a minimum number of gensets online

- The engines are equipped with the latest generation of common-rail systems and can be adapted to operate on low or neutral CO2 fuels.

Documents

-

PR Cadeler WTIV_EN

Contact

Nils Søholt

Trade Press Marine

Group Communications & MarktingEverllenceTeglholmsgade 412450 Copenhagen SVDenmark

nils.soeholt@everllence.com t +45 33 85 26 69Available languages

- DE ·

- EN

Get notified about press releases

Find out how we can help you

Get in touch with our offshore vessel experts and discover how we can create an efficient and future-proof solution for your wind farm installation vessels.

Continue reading

MAN Energy Solutions is now Everllence.

We have adopted a new brand name and moved to a new domain: www.everllence.com. This page will also be relocated there shortly. We are working on shifting all pages to www.everllence.com.