Increasing the yield: More effective fertilizer production

The world is hungrier than ever, putting enormous pressure on crop producers to increase their yields. The importance of fertilizers is only set to grow. Their production, however, is extremely energy-intensive. As a producer, you will be looking to optimize your operations, preparing your business for a CO2-neutral future and cutting operating costs. Give your business the edge with powerful, highly efficient compressor trains from MAN Energy Solutions.

Single source, full spectrum: The complete range of machinery to optimize your energy-intensive industry

MAN Energy Solutions compressors and drives are used in fertilizer plants around the world to generate ammonia, urea or nitric acid – basic chemicals used for fertilizers.

Whichever process you are invested in, our machinery is highly efficient, robust and reliable, giving you the edge in an industry which has a considerable impact on the environment. We support you in your efforts to reduce greenhouse gas emissions and make sure your business runs smoothly. We not only supply the full range of compressors; we offer the steam turbines which mostly power production trains. In fact, you can order an entire train from us, tailor-made for your specific requirements.

Explore our specialist offers for your industry

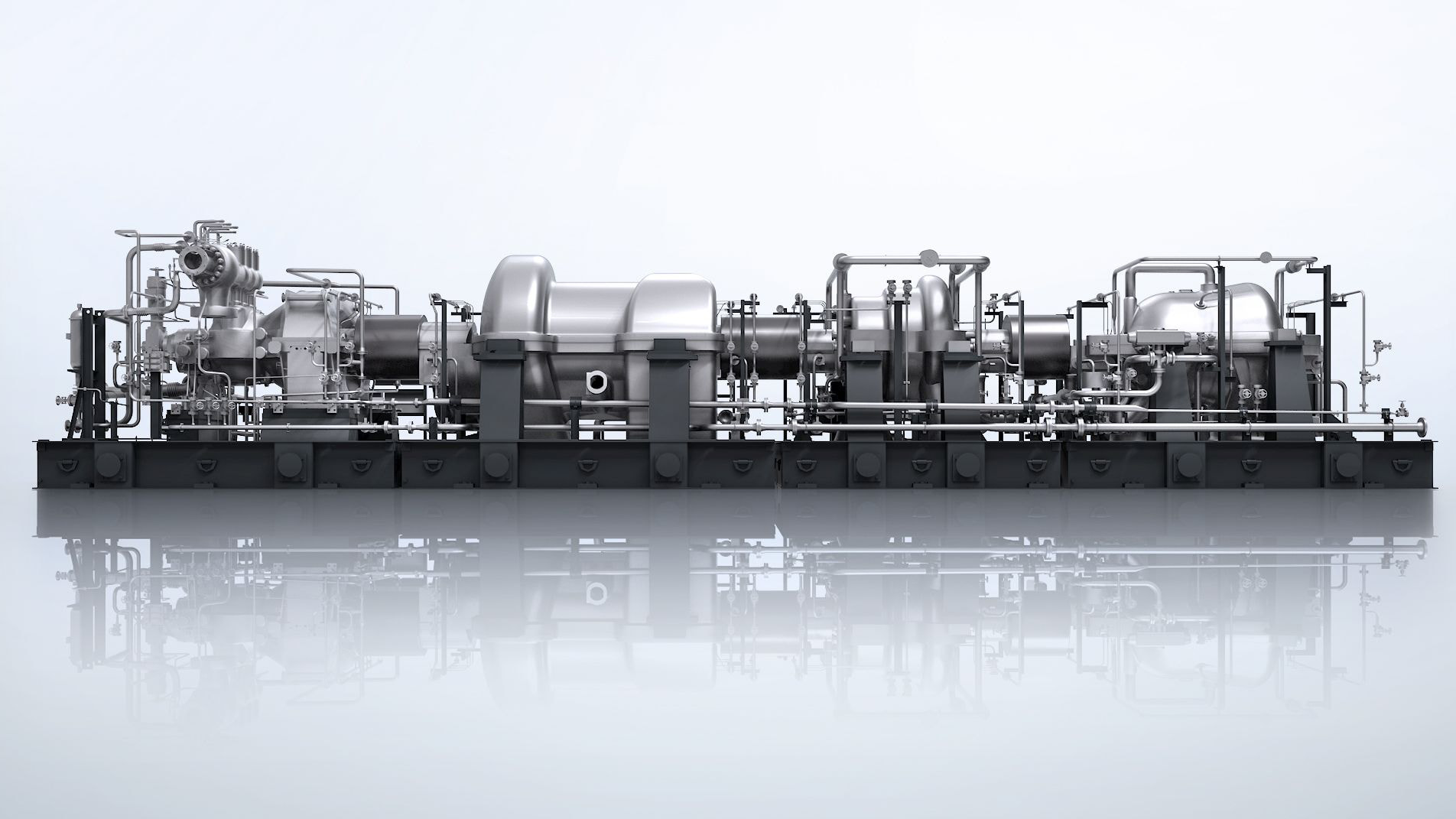

NAMAX train for nitric acid processes

The nitric acid production process often requires a dual-pressure process. Our NAMAX train concept increases the power density and enables higher rotational speed to its process, thereby boosting the efficiency of nitric acid production. Since we have integrated our AR-MAX1 air compressor into the train, all components can run at the same speed, making the intermediate gearbox a thing of the past.

All components and services from a single source to the benefit of your business.

How you benefit:

- Reduced energy footprint

- Highest mechanical robustness, increased availability

- Compact modular train with lower weight

- Simpler logistics, installation, and commissioning

- More flexibility in train arrangement

- No gearbox-related frictional losses and maintenance costs

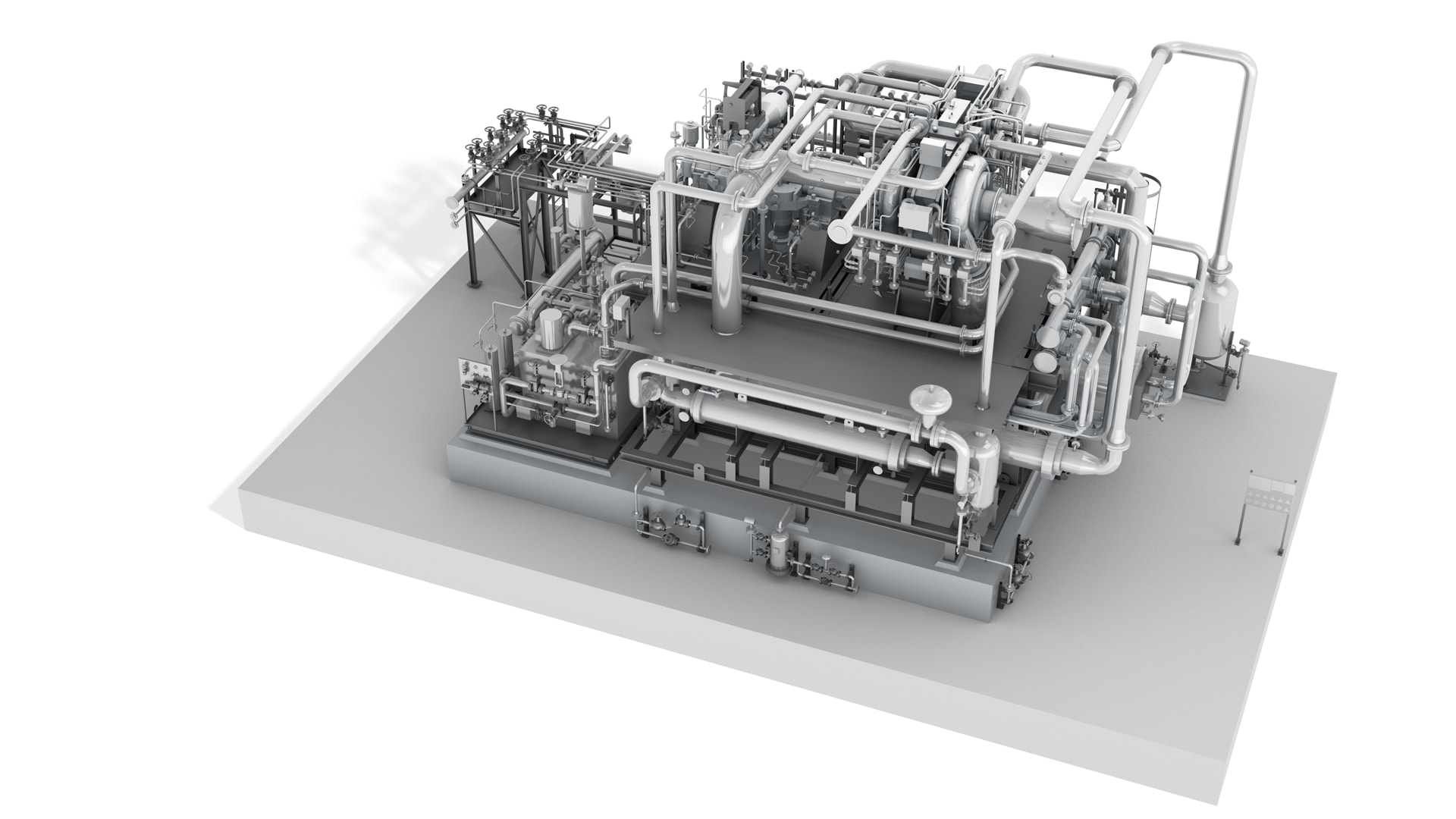

Compressors for ammonia and urea plants

We supply the full turbomachinery portfolio you need for safe and reliable production at the lowest possible cost.

In ammonia and urea production processes, compressors generate the pressures of the various gaseous media required. MAN Energy Solutions supplies both the individual and full train solutions used in your industry. Our range of compressors comprises:

- Natural gas compressors

- Syngas compressors

- Air compressors

- Ammonia compressors

Carbon dioxide compressors (integrally geared type) for urea production. These compressors are usually driven by steam turbines. We also supply these as well as alternative drives, giving you the option of a one-stop shop for a highly efficient and reliable production system.

How you benefit:

- Highly cost-efficient

- Perfectly matched components

- Reliable operation with maximum uptime

MAN PrimeServ keeps your turbomachinery running

MAN PrimeServ is the perfect complement to our excellent compressors and drives. Our service engineers are always available to answer questions, assist in troubleshooting and get your facilities up and running in no time – wherever and whenever you need them.

How you benefit:

- Fast, reliable and expert customer support

- Individual O&M contracts

- Global service – 24 hours a day, 365 days a year

Robust and reliable compressor trains at work

Fertilizer producers all around the world rely on superior turbomachinery from MAN Energy Solutions

Nitric acid compressor train, Spain and Australia.

Contact our MAN Process Industry support team

Are you in the fertilizer production business? Would you like to optimize your processes?

MAN Energy Solutions has the products and the expertise to prepare your business for a competitive future. Find out how our compressor trains can benefit your operations.