Scarcity of resources: A challenge for the process industry

MAN Energy Solutions has the technology which allows you use the earth's resources in a responsible and ultimately sustainable way. We specialize in highly efficient machinery, designed to perfectly meet your process requirements.

The carbon puzzle

Whilst conventional technology allows for large savings in efficiency, only radical innovation can bring a serious cut in greenhouse gas emissions.

Polymers, specialized fuels, fertilizers, pulp and paper, industrial gases, you name it: The process industry is working round the clock to supply its customers with the products they need and demand. However, in light of global warming and obligations derived from the Paris Agreement, environmental and general resource restraints impact the daily running and general planning of all industries. Increasing your output whilst employing ultra-efficient machinery is one way of working towards a greener economy. After all, using less fuel to produce the same is already a step in the right direction.

However, it might not be enough. Most developed economies are currently far off the mark when it comes to meeting their Paris Agreement targets and more decisive steps are needed. Cutting carbon emissions and using renewable energy sources are among the main levers for optimizing your processes. MAN Energy Solutions is a leader in innovative technologies which support the process industries in working towards a resource-compatible future.

Leverage new technologies – work with the experts

Turning back the clock is not an option when it comes to global warming. At MAN Energy Solutions, we are pressing ahead, developing the innovations which support you in aligning your industry with the environmental requirements of the day.

From waste to valuable material

Getting more out of your processes

Technological advances with respect to running process industry plants focus on three core aspects of cutting carbon emissions.

One means aiming for a circular economy by closing the carbon loop. Concepts such as carbon capture utilization (CCU) are being explored in this context. This means turning waste gases into valuable materials. Our customers are interested in power-to-X (PtX) technologies and we are frequently working on pilot plant studies to see how far the carbon loop can be closed.

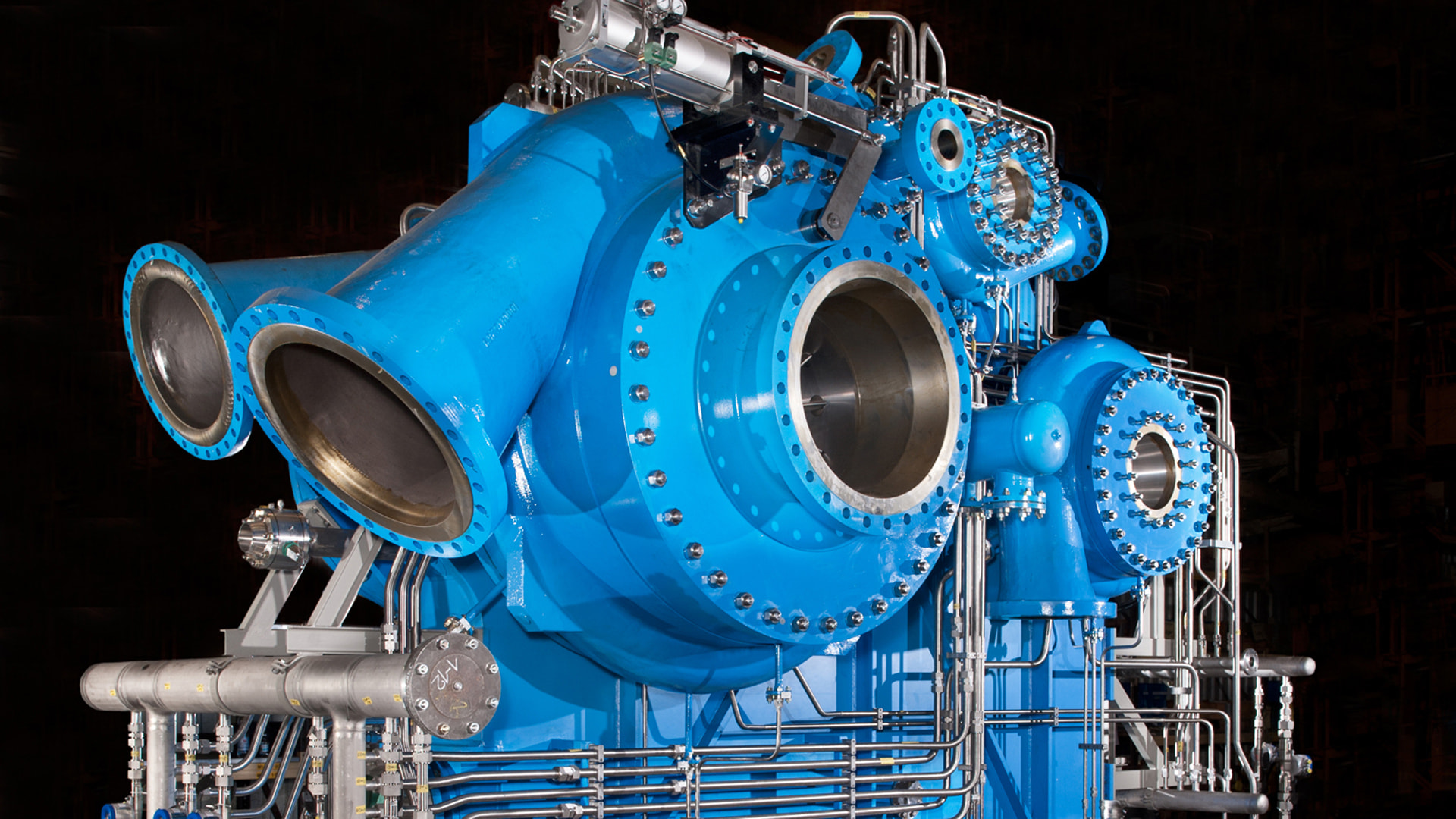

The second means avoiding carbon emissions through efficiency. For decades, we have been developing, manufacturing and improving our compressor trains for industry. We always focus on reliability, minimal downtime and utmost efficiency because we understand that these are our customers' priorities. We are constantly looking for possible improvements related to new blade stages, stators, more efficient gearboxes and the like. This has enabled us to design the RG integrally geared compressor for the most efficient CO2 recovery from industrial emissions.

Finally, the third aims to capture and sequester the carbon emissions in geological formations using MAN Energy Solutions efficient compression technology.

DWE reactor services

Pilot plant studies (R&D)

We minimize your innovation risk by running pilot plant studies at our premises. We help you select the best heat transfer medium for your given process conditions. In pilot reactors, chemical syntheses are trialed on a small scale (gram to kilogram volumes) in order to manufacture the desired quantity of product using the least amount of raw materials. We scale up from one-tube pilot reactors or demonstration plants to world-scale plants running for you. We also simulate critical operating conditions and perform long-term trials, for example to determine the continuity of certain processes or the ageing of catalysts.

We minimize your innovation risk by running pilot plant studies at our premises. We help you select the best heat transfer medium for your given process conditions. In pilot reactors, chemical syntheses are trialed on a small scale (gram to kilogram volumes) in order to manufacture the desired quantity of product using the least amount of raw materials. We scale up from one-tube pilot reactors or demonstration plants to world-scale plants running for you. We also simulate critical operating conditions and perform long-term trials, for example to determine the continuity of certain processes or the ageing of catalysts.

Molten salt energy storage (MOSAS)

This reliable technology can be integrated into various applications to ensure a secure power supply. It basically is thermal energy storage which is used to deliver reliable power in line with your operational demands. Storage is provided in special purpose-built vessels with naturally occurring salts. The energy is released when needed for powering a steam turbine which in turn drives a compressor. This can compensate for volatility, making electricity from renewables a completely reliable source of energy. Using MOSAS means you can switch to renewable power supplies. There is more to MOSAS than that and we are constantly working to increase its innovative and green potential.

This reliable technology can be integrated into various applications to ensure a secure power supply. It basically is thermal energy storage which is used to deliver reliable power in line with your operational demands. Storage is provided in special purpose-built vessels with naturally occurring salts. The energy is released when needed for powering a steam turbine which in turn drives a compressor. This can compensate for volatility, making electricity from renewables a completely reliable source of energy. Using MOSAS means you can switch to renewable power supplies. There is more to MOSAS than that and we are constantly working to increase its innovative and green potential.

Power-to-X

Electricity can be much more than simply a final energy product. It can be a source of sustainable and resource-conserving power for the process industry, coupled by PtX. Converting renewable electricity into synthetic gas or hydrogen makes its energy available when and wherever it is required while keeping the CO2 count down. MAN Energy Solutions power-to-X (MAN PtX) is a sustainable solution for synthetic fuel production and long-term energy storage.

Electricity can be much more than simply a final energy product. It can be a source of sustainable and resource-conserving power for the process industry, coupled by PtX. Converting renewable electricity into synthetic gas or hydrogen makes its energy available when and wherever it is required while keeping the CO2 count down. MAN Energy Solutions power-to-X (MAN PtX) is a sustainable solution for synthetic fuel production and long-term energy storage.

RFCC/FCC units and turnarounds

The RFCC/FCC processes at the heart of the refinery business must run as smoothly as possible to guarantee profitability. As specialist supplier, we provide our customers with components and complete systems for petrochemical processes. We offer engineering studies, workshop fabrication, transportation, on-site assembly, maintenance, service and everything in between.

The RFCC/FCC processes at the heart of the refinery business must run as smoothly as possible to guarantee profitability. As specialist supplier, we provide our customers with components and complete systems for petrochemical processes. We offer engineering studies, workshop fabrication, transportation, on-site assembly, maintenance, service and everything in between.

Blast furnace gas to bioethanol

Using fossil fuels, the steel industry is a CO2-heavy industry. However, new technology from MAN Energy Solutions allows our customer to produce bioethanol from the waste gases produced by its steelworks in Belgium. This process will run from 2020 with a solution that consists of a three-stage geared compressor, including a dry separator (scrubber), cooler, piping system and instrumentation in a complete turnkey installation. In recognition of this effort to decarbonize, the EU has called this a major step towards a “steelworks for the future with zero emissions”.

Using fossil fuels, the steel industry is a CO2-heavy industry. However, new technology from MAN Energy Solutions allows our customer to produce bioethanol from the waste gases produced by its steelworks in Belgium. This process will run from 2020 with a solution that consists of a three-stage geared compressor, including a dry separator (scrubber), cooler, piping system and instrumentation in a complete turnkey installation. In recognition of this effort to decarbonize, the EU has called this a major step towards a “steelworks for the future with zero emissions”.

Carbon capture and storage

Another mechanism to prevent carbon emissions, carbon capture and waste heat recovery can help you to significantly decrease your greenhouse gas footprint. We supply the technology for the compression of CO2/super-critical CO2, for the liquefaction of CO2 and for heat recovery and heat integration for your process plant.

Another mechanism to prevent carbon emissions, carbon capture and waste heat recovery can help you to significantly decrease your greenhouse gas footprint. We supply the technology for the compression of CO2/super-critical CO2, for the liquefaction of CO2 and for heat recovery and heat integration for your process plant.

MAN PrimeServ keeps your turbomachinery running

Our service engineers provide preventive maintenance, assist your troubleshooting, and get your facilities up and running in no time – wherever and whenever you need them.

How you benefit:

- Fast, reliable and expert customer support

- Bespoke service agreements

- Global service – 24 hours a day, 365 days a year

Contact our experts

Are you in the process industry and looking to optimize your operations from an environmental as well as ROI point of view?

See how new technologies developed by MAN Energy Solutions can support your business.

MAN Energy Solutions is now Everllence.

We have adopted a new brand name and moved to a new domain: www.everllence.com. This page will also be relocated there shortly. We are working on shifting all pages to www.everllence.com.