TBO extension from MAN PrimeServ

The cost pressure is high in the maritime industry: The effects of the coronavirus pandemic, with its resulting lockdowns and travel restrictions, in particular have resulted in radical changes and the need for increased flexibility and reduced costs.

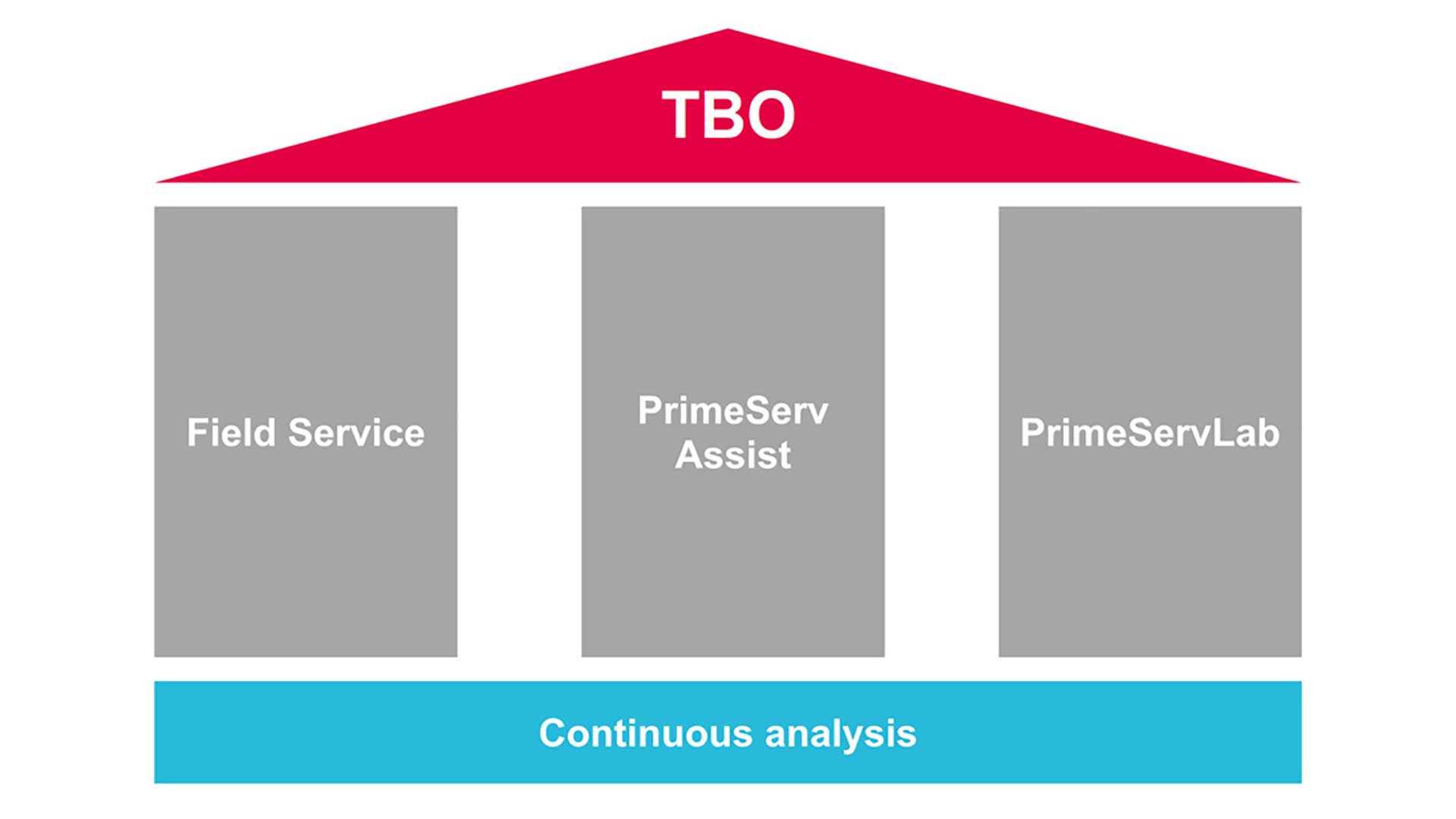

In order to meet these needs, the MAN PrimeServ range includes an offer that can be individually adapted to each customer: The TBO extension. TBO stands for "time between overhaul", in other words, the standard maintenance interval. Thanks to this individual customization and extension of maintenance intervals for important ship components, significant savings can be achieved. The process has three steps: From the on-site inventory and real-time digital data monitoring, through to the laboratory testing of the relevant operating media. The credo: Small measure, large effect! MAN Energy Solutions takes a holistic approach and is already tackling the challenges of tomorrow – for sustainable value creation for the customer.

Reliable engines with an individual service offering

Marine engines from MAN Energy Solutions stand out thanks to their reliability, robustness and efficiency.

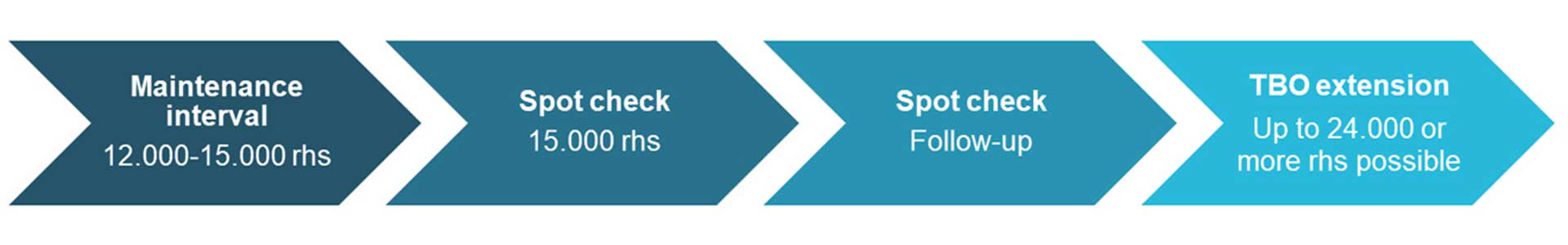

They are designed for optimal performance in various application and operating conditions. However, with the delivery of new engines, the job is far from complete. MAN PrimeServ, the after-sales team, keeps an eye on the engines. An example of this is a Danish offshore company, with whom the team collaborated to individually adapt the maintenance schedule for the fleet. For this, the fleet of ships was intensively monitored over several years, and all test results for the engines were statistically recorded and evaluated. As a result of this, it was possible to significantly adapt the maintenance times for some main components. The maintenance interval for the cylinder heads, cylinder liners and pistons was therefore increased from 12,000 to 24,000 operating hours, for example. Positive effect for the customer: A big increase in flexibility for their maintenance schedule and considerable maintenance costs savings.

Prerequisites for a TBO extension:

- Larger engine overhauls must be carried out together with the MAN Energy Solutions personnel.

- Exclusive use of MAN original parts

- Continuous monitoring of the engine's operating conditions via "PrimeServ Assist" and "PrimeServLab"

- The engine only operates with specified operating media

- The general operating condition of the engine remains unchanged – in accordance with MAN Energy Solutions' specifications

- Compliance with the standard maintenance intervals

Specialist knowledge is important – but equally important is the ability to recognize small details that can have a big effect.

Full steam ahead into the future – with additional individual and proactive service ranges

With the expertise of the Original Equipment Manufacturer (OEM) and unrivalled knowledge, MAN PrimeServ is excellently positioned to offer the best-possible service solutions, even in the future – thanks to the focus on individual customer requirements and access to the most advanced service technology. The perfect combination of analog and digital services results in a "watertight" maintenance system that benefits all parties. MAN PrimeServ cannot guarantee great weather and a calm sea, but it can guarantee rapid-response, proactive and expert support with real-time service.

We want to prevent downtimes and damage, and detect minor damage in good time before it results in greater damage.

Maintenance work on important ship components, such as the main and auxiliary machinery, is usually associated with long idle times. During this time, the ship must be taken out of operative business and is unable to contribute to the company's turnover. Where possible, such maintenance work should therefore be carried out during dock periods that are already necessary. This is where the tried-and-tested after-sales service MAN PrimeServ comes into play: Customers receive individually tailored consulting and expertise. Furthermore, an analysis is carried out, which explains what is technically feasible and what makes economic sense.

Monitoring and checking the engine regularly means that the maintenance intervals can be extended. However, an extension depends on various factors: In addition to the operating condition, the type and quality of fuel that is used, the lubricating oil care and the general maintenance and care, in particular, are decisive during the assessment. Monitoring the quality of operating fluids is essential for reliable engine operation. Many operators of marine and power plant engines have decided to make use of this service in order to take precautions against damaged parts or corrosion in their engines.

Which measures therefore have to be taken in order to guarantee that the machines can operate for a long time, and how can maintenance intervals (TBO = Time Between Overhaul) be extended? PrimeServLab, MAN Energy Solutions' in-house laboratory, tackles these questions and carries out in-depth analyses.

Small damage – huge effect

With PrimeServLab, the customer is offered a unique analysis portfolio. The specific knowledge regarding engines and engine fluids means that operating material analyses can be evaluated with a high level of precision. PrimeServLab therefore does not limit the analyses to individual fluids – to build up a complete image, all of the engine fluids are tested. Thanks to comprehensive solutions, all of the important operating material analyses can therefore be covered. Furthermore, this can increase the service life of engines and identify potential problems or risks that could lead to faults. As a result, downtimes, damaged plants and increased costs that may arise for our customers are considerably reduced.

PrimeServLab was not originally designed to offer specific customer analyses. It was a learning process. Over time, additional, complex problems arose which were not foreseen in the original set-up. Analytical methods were therefore developed, i.e. not only were the standards measured but, in addition to this, methods were developed in order to solve these special problems – for example, a procedure for measuring fuel content in the lube oil. Over the years, this resulted in countless measurement procedures and methods which now help to better understand engines. The task areas are usually of a considerable size, but the sources of faults are often minute. The smallest of particles in the fluids can have a huge effect. It is therefore necessary to pay close attention and question everything.

How does the lube oil behave? Does the engine have any special requirements with regard to the lube oil? Are readjustments necessary? Do oil change intervals arise? Is the lube oil contaminated by the fuel?

A classic application: All of a customer's machines suddenly stop. The worst-case scenario for the operator. Thanks to the proven measurement method, the fuel was examined more carefully and eventually the component in the fuel responsible for the engine stopping was found. When, a year later, a fuel with the same component was supplied, the fuel analysis that was carried out was able to identify this and warn the customer against using this in good time. Major damage was therefore prevented.

We continuously monitor what is going on in the engine and in other important components, and proactively inform the customer about potential negative developments – furthermore, we can provide the customer with optimization proposals based on the data that we collect. We want to always be one step ahead!

MAN Energy Solutions offers great after-sales service with a clear performance promise, qualified and reliable experts, and individually tailored solutions. We offer a premium service that is perfectly tailored to the needs of our customers. 250 years of engineering experience speaks for itself!

Maintenance interval extension, including spot check

In the first step, the current state of the plant is analyzed on-site as part of a spot check. This is carried out by a PrimeServ superintendend engineer. In this, the most relevant parts are analyzed and samples of the relevant operating fluids are taken for subsequent analysis in the PrimeServLab.

PrimeServ Assist

PrimeServ Assist combines digital technology with in-depth MAN expertise and allows customers to get the best out of their plants and ships. Thanks to its continual analysis of operating data, the PrimeServ Assist service is the ideal solution to keep our customers' systems running at optimum efficiency for their specific application. This involves more than just an online service: PrimeServ Assist generates immediate results in the form of expert recommendations for the customer's decision-makers. These recommendations can directly affect the profitability.

PrimeServLab

Monitoring the quality of operating fluids is essential for reliable engine operation. Many operators of marine and power plant engines have decided to make use of this service in order to take precautions against damaged parts or corrosion in their engines. MAN Energy Solutions analyses heating oil, lube oil, cooling water, lube oil separator samples and fuel separator samples.

MAN Energy Solutions is now Everllence.

We have adopted a new brand name and moved to a new domain: www.everllence.com. This page will also be relocated there shortly. We are working on shifting all pages to www.everllence.com.