Ensuring a maximum integration of renewables

The southern German town of Schwäbisch Hall is known for the bank that bears its name and its historic role in salt production. However, it aspires to be known for a totally different reason – building a zero-carbon power and heating system.

By Ward Pincus

Schwäbisch Hall Municipal Utilities has set a 2035 deadline to meet 100% of its electricity and heating requirements with renewable energy.

Responsible for helping the town of 37,000 people achieve this goal, the municipal energy supplier of Schwäbisch Hall has set a 2035 deadline to meet 100% of its electricity and heating requirements with renewable energy. That’s a real challenge when temperatures remain in the single digits or even drop significantly below zero degree from November to March, and the winter seasons create the dark doldrums, or so-called Dunkelflaute in German, when there is little sun or wind to power wind and solar based renewables.

“We have a vision to be a green market leader driving the change in the way we produce energy,” explains Fabian Andrews, Head of Department Power Plants and Heat Distribution for the utility. “We are finding several ways to reduce the use of fossil fuels. We want to be a model: if we can do it, everyone can do it.”

The utility has already achieved a significant renewable energy share in its own network area from solar, wind, hydro, biomethane and biomass - but getting the rest of the way will take time. During this transition period, one of the key systems the utility is counting on is combined heat and power (CHP) plants and their primarily natural gas-fired engines. “For Schwäbisch Hall, the early establishment of a heat network was a stroke of luck,” says Andrews. “Today, we operate around 60 CHP units to generate electricity and heat from natural gas, biomethane or biogas.”

Combined efficiency of over 90 percent

CHP plants, also known as cogeneration plants, offer a number of benefits to utilities and industrial facilities looking to maximize the efficiency and minimize the emissions of their fossil-fueled power and heating assets. The combination of high electrical

efficiency, up to 50 percent, and the equally high efficiency of thermal heat offtake, such as district heating, means CHP plants can deliver an overall efficiency of more than 90 percent.

That means the energy value of the natural gas being burned in the engines is almost entirely converted to electricity and heat, with less than 10 percent lost in the process, says Dr. Tilman Tütken, Head of Sales Power Plants, Europe at MAN Energy

Solutions. “As a result, the CO2 emissions per kilowatt hour of electricity and heat produced is quite low,” he adds.

The CHP technology is an important transition technology on the road to the energy transition.

The overall efficiency of CHP plant on Alfred-Leikam-Street in Schwäbisch Hall is exceeding 90%.

Agile power plants

MAN Energy Solutions is supporting the town’s ambition by providing two gas-fired engines to replace older, less efficient engines at one of the utility’s CHP plants. The first engine was installed in 2018; the second was commissioned in 2022. Each engine has a capacity of 7.5 MW of electricity and 7.5 MW of heating capacity – more than double the capacity of the previous engines.

In addition, the electrical efficiency of the engines is increased from 39 to 47 percent compared to the previous ones. In terms of overall efficiency the plant now reaches above 90 percent that helps the utility manage the carbon intensity of energy generation, even as it adds capacity. However, CHP plants can have a dramatically larger impact on reducing emissions when utilities and industrial plants switch from coal-fired plants to lower-emission, dispatchable gas-fired engines in CHP plant configurations, Tütken says.

That impact is magnified thanks to the fuel flexibility of these engines . As a result, Schwäbisch Hall has switched the fuel powering both MAN engines from natural gas to the more environmentally friendly biomethane. The change reduces CO2 emissions by 15,000 tons/year per engine and lessens the town’s exposure to natural gas price fluctuations.

The engines also support the municipal utility’s goal of generating 100 percent of its heating supply from renewable energy sources – even the option, in the longer-term, of using synthetic fuels based on green hydrogen.

Another key benefit of gas engine CHP plants is their agility. These plants can rapidly reduce output or shut off completely, as well as quickly ramp back up, thereby allowing the utility to capture peaks in electricity prices, whether caused by fluctuating renewable power supply on the grid or rapid rises in demand.

Matching offtake supply to demand

Central to the efficiency of CHP plants, alongside the gas engines at their heart, is that the heat produced by the CHP plant shall match the changing demand from the offtaker. At Schwäbisch Hall, for example, the heat is used to power the utility’s district heating network and its nearly 100-kilometer network of piping. District heating is the principle offtake configuration for a CHP plant’s exhaust heat, but not the only one. Exhaust heat also can be piped to a nearby factory for use in a range of industrial processes, Tütken says.

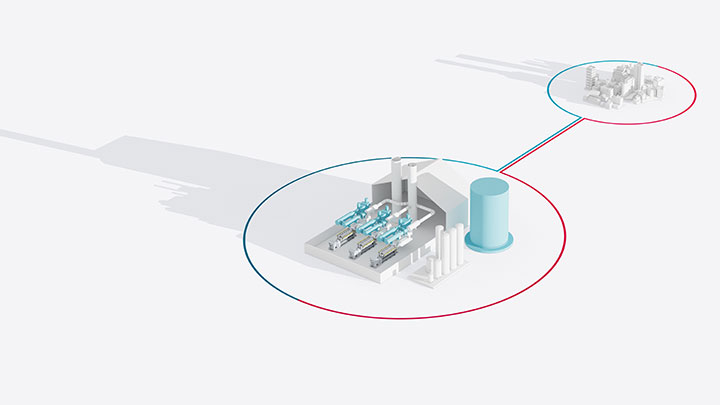

Innovative CHP configurations also are helping utilities ensure security of supply of electricity and heat, while minimizing emissions and moving toward a green energy future. For example, hot water storage tanks can be added to district heating systems to address times when electricity demand is fully covered by wind and solar based renewables, but heating demand remains strong. The storage tanks provide a buffer of several hours when CHP plants can be turned down or shut off. This is the configuration at Schwäbisch Hall. “The CHP technology allows us to optimally manage power and heat demand while integrating the maximum amount of renewables into our power and heat mix,” adds Andrews.

The CHP technology is an important transition technology on the road to the energy and heat transition.

A role in a zero-carbon future

Long term, these gas engine CHP plants can play an important role, even in a decarbonized world. That’s because they can operate on a range of fuels, including biofuels – something already happening at Schwäbisch Hall – and synthetic fuels based on green hydrogen. As these green fuels become cheaper, explains Andrews, his utility will increasingly use them in their plants.

As a result, Tütken says, CHP plants will be able to deliver dispatchable clean electricity and heat in those times when renewables can’t meet demand. “The investors we are speaking with understand that CHP, with the use of clean zero-carbon fuels, can be an important element in the design of the energy systems of the future.”

Fabian Andrews concludes, “With our 60 CHP plants in the Schwäbisch Hall region, we are proving that cogeneration with district heating is economical viable. The CHP technology is therefore an important transition technology on the road to the energy and heat transition, and Schwäbisch Hall Municipal Utilities is relying on it as part of its energy vision.”

About the author

Ward Pincus is a Dubai-based who is working in the Middle East since more than 13 years. He reports for publications in the USA, Europe, and the Middle East. He is a former correspondent for the Associated Press (AP) in the United Arab Emirates.

Explore more topics

MAN Energy Solutions is now Everllence.

We have adopted a new brand name and moved to a new domain: www.everllence.com. This page will also be relocated there shortly. We are working on shifting all pages to www.everllence.com.