Accelerating the path to a decarbonized future

The world needs quick and efficient solutions to reach carbon neutrality by 2050. A vital part of those solutions will be hydrogen and synthetic fuels derived from renewable energy using Power-to-X technology. Experts predict massive cost efficiencies once facilities on an industrial scale are established. But a fitting political framework is needed to make the shift to green hydrogen now.

By Marc Engelhardt

Our world can only partly be powered by electricity, says Marc Grünewald, Head of Business Development, Power and New Energies at MAN Energy Solutions, making the need for green hydrogen and alternative fuels necessary to decarbonize all sectors of the economy.

The call for action can’t be any clearer: “The time is right,” argues the International Energy Agency (IEA), “to tap into hydrogen’s potential to play a key role in a clean, secure and affordable energy future.” It is a message that resonates strongly with Marc Grünewald, Head of Business Development, Power and New Energies at MAN Energy Solutions: “We shouldn’t talk about solutions available in a decade or so, but act now to reduce our carbon footprint. Power-to-X is one of the technologies we have today that can lead to immediate carbon reductions and accelerate our path into a decarbonized future.”

“We live in a world that can only partly be powered by electricity”, explains Grünewald. “There are a number of use cases which call for alternative fuels – and for them sector coupling is key.” Because of its versatility, green hydrogen is the answer to these critical energy challenges.

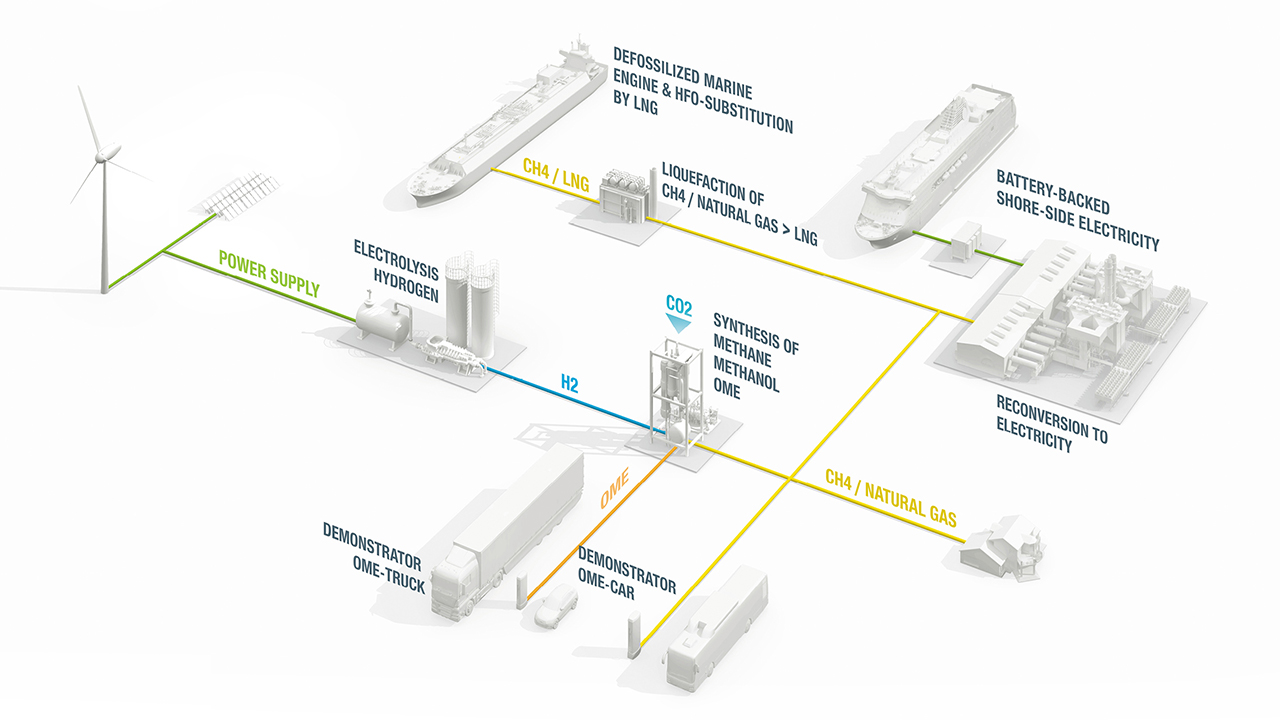

Using electrolyzers, electricity from renewable energy sources such as wind or solar can be converted into “green” hydrogen. With the help of Power-to-X technology, this hydrogen can then be further converted by a methanation reactor into synthetic natural gas or syngas (SNG) to feed gas power plants or transformed into methane for industrial processes or into other synthetic fuels for trucks, ships and planes, decarbonizing and interconnecting all sectors of the economy with the energy industry – and it’s all carbon-neutral!

Scaling up: Power-to-X goes industrial

MAN Energy Solutions is ready to build a 50 MW Power-to-X plant converting renewable energy into climate-neutral synthetic natural gas

The technologies to produce green hydrogen and synthetic fuels have already been put into small-scale production facilities. In 2013, for example, MAN Energy Solutions constructed a six-megawatt methanation reactor in Werlte, Germany, to produce syngas for the car manufacturer Audi. Thanks to the experience collected there, the technology has massively evolved.

Brunsbüttel, says Grünewald, is a perfect location: Both hydrogen and oxygen could be used by the local chemical industry, and an already planned LNG terminal at the coastal town could eventually be used to blend SNG to create greener ship fuels. “Brunsbüttel,” predicts Grünewald, “could even work as a starting point for a hydrogen pipeline to Hamburg, a city of two million only 100 kilometers away.”

What is lacking, however, is an adequate framework to make plants like the one in Brunsbüttel competitive. “Producing green hydrogen today costs three to four times more than black hydrogen produced from gas and oil,” Grünewald criticizes. “Green hydrogen needs carbon pricing to make it competitive on the market.”

Carbon prices of between 25 and 55 euros per ton of CO2 equivalent currently envisaged for Germany will be too low to create the necessary shift. “Who would want to invest into a plant that will eventually produce a fuel costing four times as much as its fossil counterpart,” MAN Energy Solutions’ Vice President wonders.

Another important factor to make viable business cases for Power-to-X-technology is cheap and ample renewable energy, since it is the primary resource for green fuels. And last but not least, Grünewald calls for tax incentives. “In Germany, we can produce renewable energy for three to four euro cents per Kilowatt-hour, but government taxes add another seven cents, which makes running an electrolyzer economically unviable.”

Green hydrogen can be stored and transported using the infrastructure for gas pipelines already in place.

Scaling out: Coupling sectors beyond electric

The benefits of hydrogen and its derivate synthetic fuels are obvious. But most of all, they have the potential to decarbonize sectors otherwise hard to change. Take maritime shipping for example: “Cruise ship companies like AIDA,” Grünewald points out, “have already replaced huge 60-megawatt diesel engines with ones powered by LNG, decreasing carbon emissions by 20 percent.” But for shipping to reach its self-set goal of reducing carbon emissions by half in 2050, synthetic carbon-free fuels generated from renewable energy will have to replace LNG. “The question is how to green the combustion engine; the answer is use green fuels.”

Wes Amelie, a 1,036-teu feeder container ship that was retrofitted in 2017 to allow for dual-fuel operation, is a perfect illustration of how shipping already can move forward by blending fuels.

To showcase the potential synthetic fuels have for shipping, the vessel owned by Wessels Reederei will replace 20 of the 120 tons of LNG that it typically uses for a round trip with climate-neutral SNG produced by the Power-to-Gas plant at Audi in Werlte. As a result, the company expects carbon emissions for Wes Amelie to decline by 56 tons.

Transforming the power business: By coupling disparate sectors, Power-to-X technology not only opens up new pathways for decarbonization but also entirely new business models for the energy industry.

Industry provides another example: According to the IEA, the production of hydrogen for industrial processes – almost entirely supplied from coal and natural gas today – emits the same amount of carbon dioxide into the atmosphere each year as the United Kingdom and Indonesia combined. Greening industrial hydrogen would mean considerable gains toward decarbonization. “Many companies have already declared interest in green hydrogen from Power-to-X plants,” Grünewald says, “but it all depends on the price.” Again, restrictions as well as market-based price signals will be needed to discourage the further use of carbon-based hydrogen. The same is true for heavy transport, industrial heating and heating in general.

Because they can use the existing infrastructure for transport and distribution and the existing engine technology, fuels derived from Power-to-X will couple these disparate sectors in the long run – helping the world economy become carbon neutral while at the same time generating entirely new business opportunities and business models for the energy industry.

Tipping the scales: the emergence of a global Power-to-X market

Power-to-X: the heart of a decarbonized energy supply

The rise of Power-to-X technology is a global phenomenon. In those parts of the world where sun and wind are prevalent, costs of renewable energy have been declining, creating hotspots for a hydrogen economy. Australia, Northern Africa and Patagonia, says Grünewald, are just some examples where large-scale projects are already being planned. Thanks to Power-to-X, these regions could become exporters of green fuels, producing, selling and transporting syngas or methanol on the world market just as oil and gas are today. “Of course MAN Energy Solutions, with presences in more than 120 countries, offers the necessary technology worldwide,” Grünewald emphasizes.

The global nature of the market underlines the need for global regulations, as well as a global carbon price or trading system that is binding for everyone. The stage is set and the general outlook is bright: Experts expect the cost of green hydrogen to fall sharply.

The IEA predicts a decline of 30 percent in their The Future of Hydrogen report and cost parity for a number of use cases representing 15 percent of the world’s total energy consumption. The IEA also maintains that to reach the aims of the historic Paris Agreement and keep the increase in global warming under 2 degrees Celsius above preindustrial levels by the year 2050, green hydrogen is “required” as a key feature. In other words, Power-to-X is not a nice-to-have, but a must-have for the future of our planet. And there is not much time left to give it its rightful place.

We shouldn’t talk about solutions available in a decade or so, but act now to reduce our carbon footprint.

About the author

Marc Engelhardt is an independent journalist based in Geneva, where he reports on the United Nations, international organizations and global developments in economics, science, politics and energy.

More about Power-to-X

MAN Energy Solutions is now Everllence.

We have adopted a new brand name and moved to a new domain: www.everllence.com. This page will also be relocated there shortly. We are working on shifting all pages to www.everllence.com.