Enabling a scalable energy transition

The MAN B&W ME-LGIM two-stroke dual-fuel engine can run on methanol as well as conventional fuels. Specifically designed to meet the needs of the maritime industry, it is a versatile and scalable solution that is suited to a wide range of vessel types. Simple handling, storage, and bunkering of methanol, combined with relatively simple auxiliary systems and the potential to be carbon-neutral, makes it an attractive option for meeting decarbonization targets.

Proven two-stroke methanol engine design

Available either for newbuilds or for upgrading existing conventional fuel vessels, this engine represents a proven, refined engine design based on over 600,000 running hours on methanol alone. Methanol produced from renewable sources is an attractive marine fuel option due to its low carbon intensity. An engine using green methanol can even provide carbon-neutral propulsion.

Key benefits

A new design for efficient methanol combustion

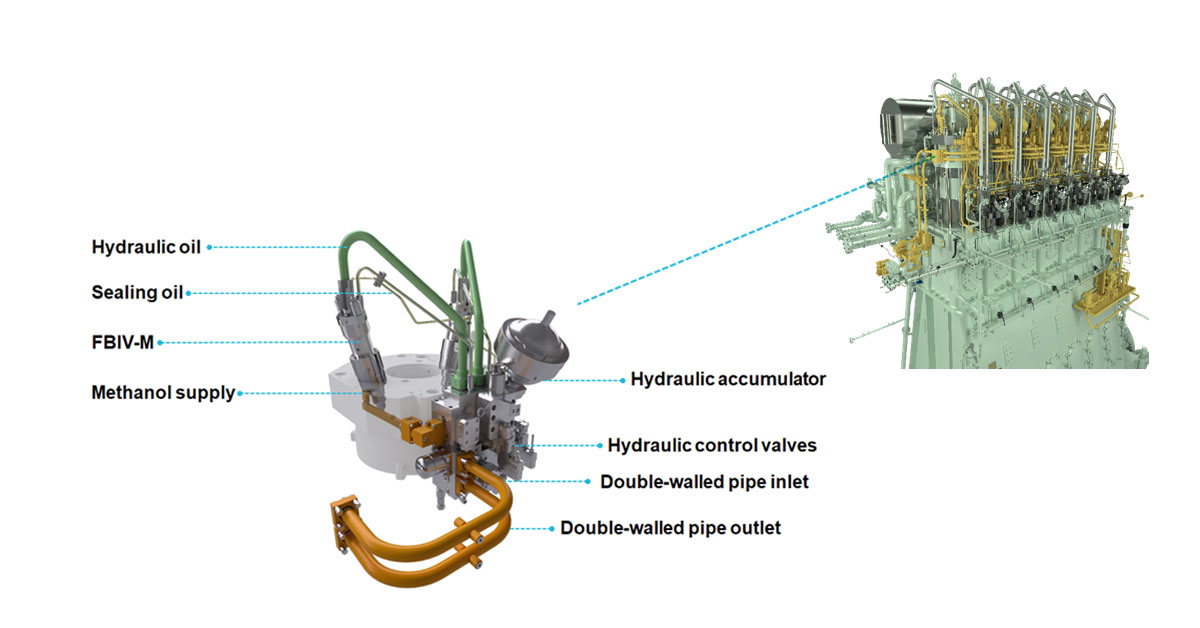

The ME-LGIM engine has inherited well-known components of our standard two-stroke diesel engine, like the ME-GI dual-fuel engine. Beneficial features of the standard MAN B&W two-stroke diesel engine have been retained. This illustration highlights methanol components and pipes that have been added to the cylinder top for methanol combustion.

The use of methanol as fuel type supports cost-effective vessel designs.

Moving together into a sustainable future

Learn more about the MAN B&W ME-LGIM engine

Continue reading

-

MAN B&W ME-LGIMpdf, 504 KB

Related products

Related News

Matson Signs Contract for ME-GI Retrofit

Matson Navigation Inc. and MAN Energy Solutions have signed a contract for the retrofit of the main engine aboard the ‘Daniel K. Inouye’, a container ship in the Matson fleet. Constructed in 2018, MAN Energy Solutions’ after-sales division, MAN PrimeServ, will retrofit the 3,600 teu vessel’s MAN B&W 7S90ME-C engine to an MAN B&W 7S90ME-GI type capable of operating on LNG and fuel oil. The contract includes an option for a second vessel.

Jens Seeberg, Head of Retrofit & Upgrades at MAN Energy Solutions, PrimeServ Denmark said: “Retrofitting an MAN B&W engine to dual-fuel running is a straightforward, proven process as our standard, electronic diesel engines are already built as ‘dual-fuel ready’ and are therefore readily convertible. Dual-fuel retrofits offer a viable pathway to shipowners such as Matson who foster a company-wide ethic of environmental sustainability and wish to achieve a net-zero carbon footprint by 2050. Ultimately, when bio-LNG and SNG come on-line in sufficient volumes, ME-GI engines operating on these fuels will also satisfy such net-zero aspirations.”

MAN Energy Solutions states that, as the lowest carbon-intensity fuel, operation on LNG is projected to reduce the Daniel K Inouye’s CO2 emissions by 24% with a maximum, guaranteed, ultra-low methane slip of between 0.20-0.28 g/kWh across the load envelope.

As part of the retrofit solution, MAN Energy Solutions will also provide a Pump and Vaporizer Unit (PVU), the prefered high-pressure pump and vaporizer for MAN B&W ME-GI engines, which will be integrated into the Daniel K Inouye’s Fuel Gas Supply System (FGSS). The PVU pressurises LNG to 300 bar and vaporises the liquefied fuel to gaseous form for supply to the main engine. Furthermore, its control system is based on that of the MAN B&W ME-GI engine and thus offers seamless integration and high performance in gas-mode.

Post-retrofit, the Daniel K. Inouye is expected to continue to operate on trans-Pacific routes between the US West Coast and Asia from mid-2023.

The ME-GI engine – the new industrial standard

MAN Energy Solutions’ successful ME-GI (-Gas Injection) engine has set a new industrial standard for two-stroke propulsion engines aboard – among others – container vessels, bulk carriers, tankers, LNG carriers and car carriers. The ME-GI engine provides ship-owners and operators with a peerless solution within environmentally friendly and high-efficiency, two-stroke technology, without the greenhouse emissions such as methane slip that are characteristic of other engines.

With the ME-GI engine, two-stroke development has taken a step further by combining the unique properties of multi-fuel combustion and the well-known reliability of MAN Energy Solutions ME-engine. The Diesel principle not only provides the ME-GI engine with high operational stability and efficiency, but also ensures 100% reliable operation during load changes on gas with just normal additions of pilot-oil amounts. The high-pressure Diesel cycle ensures complete combusion of gas, ensuring neglible methane slip. Furthermore, the ME-GI operational principles features a seamless change-over between gas operation and diesel operation. The ME-GI engine is the most environmentally-friendly technology available within the LNG-fuelled, two-stroke engine segment.

MAN Energy Solutions has also developed an ME-LGI (-Liquid Gas Injection) dual-fuel engine that expands the company’s dual-fuel portfolio, enabling the use of other, alternative fuels such as LPG, methanol and ammonia.

Per Rud, Senior Vice President, After-Sales Marine & Power, MAN PrimeServ said: ”We are grateful for our long relationship with Matson and the trust it has placed in MAN Energy Solutions. We will deliver this project by using the experience we have gained from our strong track record within dual-fuel retrofits. Matson has shown great market leadership by moving ahead with this dual-fuel retrofit. If peers in the shipping industry follow suit with large-scale retrofitting of ships, I believe that the industry can achieve its 2050 decarbonisation goals.”

About Matson

Matson, Inc. is an American transportation-services company founded in 1882. Its subsidiary, Matson Navigation Company, provides ocean shipping services across the Pacific to Hawaii, Alaska, Guam, Micronesia, the South Pacific, China, and Japan.

Documents

-

Final_PR Matson ME-GI_EN

Contact

Nils Søholt

Trade Press Marine

Group Communications & MarktingMAN Energy SolutionsTeglholmsgade 412450 Copenhagen SVDenmark

nils.soeholt@man-es.com t +45 33 85 26 69Available languages

- DE ·

- EN

Get notified about press releases

Alternative fuels for your two-stroke powered vessel: Ammonia, methanol and methane in focus

Watch the recording of our latest MAN ExpertTalk on alternative fuels for large merchant marine vessels. Get insights into the most promising marine fuels of the expected future fuel mix for two-stroke vessels, namely ammonia, methanol and methane.

You can also look forward to hearing about the latest product developments and applications as well as reasons why these fuels have the potential to offer a straightforward path for the future maritime energy transition.