Encountering critical challenges at sea

Higher fuel costs and increased exhaust emissions regulations are major challenges which are facing the marine industry today. Technologies and practices to increase efficiency are essential to ensure the long-term profitability and sustainability of this sector.

Inefficiencies impact the bottom line and the environment

While still considered the most important form of bulk transportation, the shipping industry has recognized many potential areas for improvement. To stay competitive, it is necessary to keep operating costs as low as possible – including the cost of fuel, which represents one of the most pressing issues for ships. This means using technologies that help ships use less fuel and cut energy consumption overall.

At the same time, the industry needs to comply with all current and future regulations to reduce the environmental impact caused by greenhouse gases and other pollutants. New ships are required to meet the criteria defined in the Energy Efficiency Design Index (EEDI), which promotes the use of energy-efficient equipment and engines that create less pollution. Stakeholders also want highly efficient ships with an excellent energy footprint that produce fewer greenhouse emissions and minimize their CO2 footprint.

MAN solutions for marine efficiency

MAN Efficiency Control technologies improve a ship's fuel economy to cut fuel consumption and emissions. In this way, we help ships meet all current and future regulations, including EEDI guidelines, while reducing their overall environmental impact.

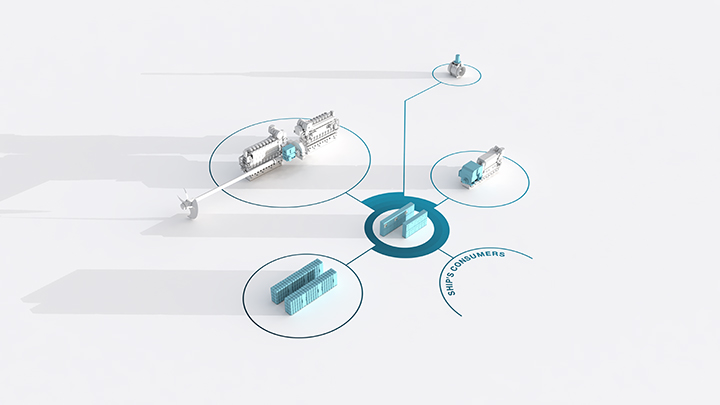

We offer our Efficiency Control technologies as part of MAN ECO CONTROL, a portfolio of technologies that will help optimize ship performance in terms of emissions, economy and operation. Ship operators benefit from smart processes, efficient operation and predictive maintenance services.

Optimized propulsion

MAN has over a century of expertise in complete propulsion packages, dating back to the first Alpha controllable pitch propeller in 1902. We take a holistic approach to your ship, examining the operational profile to optimize all relevant components – from the engine to the rudder, including all speed, maneuvering and load control settings. Whatever your needs may be, we can design the most efficient propulsion control system for your specific operational profile to make your ship greener.

For example, our MAN Alphatronic 3000 propulsion control system optimizes propeller function as well as engine operation for better maneuverability and overall efficiency. We use RENK gearboxes, efficient MAN Alpha propellers and propeller shafts to ensure reliability and top performance with a smaller environmental impact. We can also retrofit propulsion packages for all types of ships with four-stroke engines when their operational profiles change – from tug boats to cruise liners.

How you benefit:

- Increased fuel efficiency

- Improved performance

- Solutions for your specific needs

- Optimized for your ship’s operational profile

- All components from a single source

- One point of contact, one contract

Battery-hybrid

MAN offers marine battery-hybrid systems, which combine combustion engines with additional batteries to capture and store electric power, optimizing engine operation and loading. We acquired a 40 percent stake in Aspin Kemp & Associates (AKA), a specialist in the integration of electric propulsion and energy storage systems to enhance our expertise and range of products in this field.

We also offer fully customized hybrid propulsion systems, in which mechanical and electric engines work together to provide power for propulsion and hotel loads. These are ideal for vessels with flexible operation profiles and running hours with varying power demands. For example, the versatile MAN HyProp ECO combines a diesel engine with an electric shaft machine for a highly reliable propulsion system. It has several operation modes, allowing operators to optimize the propulsion train performance and fuel consumption, and even integrate batteries or energy storage devices.

How you benefit:

- Increased fuel efficiency

- Fewer NOx, SOx and CO2 emissions

- Quieter operation

- Battery power enhances existing engine power

- Wide range of operation modes

- Improved performance

Dual Fuel & LNG Gas

After our 2016 acquisition of Cryo AB, a manufacturer of cryogenic equipment with over 50 years’ experience in Liquefied Natural Gases (LNG), MAN Energy Solutions created the MAN Cryo product brand – the perfect complement to our dual fuel engines. We offer solutions for comprehensive engine and fuel gas supply systems (FGSS), offshore and onshore bunkering systems, and stationary distribution systems for regasification or fuel filling – all from a single source.

We can tailor our dual fuel propulsion systems to meet every requirement: from LNG technology for dual fuel propulsion to complete LNG handling systems (including carriers, floating storage and regasification units, feeder and bunker vessels). Our global service network and unparalleled expertise make us the ideal partner for every situation, from new engines to retrofitting or complete gas systems.

How you benefit:

- Increased fuel efficiency

- Clean burning gas, fewer NOx emissions

- Lower operating costs

- Dual fuel system means flexibility and fuel independence

- One point of contact for all components, training and support

MAN ECOCHARGE

Our MAN ECOCHARGE two-stage turbocharging technology is designed for high- and medium-speed engines of all fuel types and all engine power ranges. This compact unit is available in a variety of product types and sizes, providing excellent turbocharging efficiency that fits every engine.

With MAN ECOCHARGE, a smaller engine can generate the same amount of power while reducing specific fuel oil consumption (SFOC). Higher scavenging air pressures of up to 10.5 bar allow improved Miller timing, which reduces NOx emissions in compliance with IMO Tier III emission regulations. As a smaller high-pressure stage turbocharger, MAN ECOCHARGE results in an improved dynamic response.

How you benefit:

- Increased turbocharging efficiency

- Same power with less SFOC

- Fewer NOx emissions

- Compliant with IMO Tier III regulations

- Compact size, compatible with a variety of engines

- Improved performance

Service solutions for optimum cost-efficiency

MAN PrimeServ offers advanced modernization solutions to optimize the reliability, availability, and economic efficiency of existing equipment. Furthermore, MAN’s modernization and retrofit solutions are tailor-made to customers’ specific applications and machinery.

World's first LNG fueled bulk carrier

The Ilshin Green Iris is the world’s first LNG-fueled bulk carrier, constructed at Hyundai Mipo Dockyard (HMD) in South Korea for Ilshin Logistics. It is powered by a dual fuel ME-GI (Gas Injection) engine from MAN Energy Solutions.

| Customer: | Ilshin Logistics |

| Application: | LNG fueled bulk carrier |

| Location: | South Korea |

| Completion: | April 2018 |

| Fuel: | LNG |

| MAN’s Work Scope: | MAN B&W ME GI engine |

Our Efficiency Control applications

Innovative Efficiency Control solutions solve major marine industry challenges

- Increase fuel efficiency for reduced fuel costs

- Reduced emissions for an improved greenhouse footprint

- Improved engine performance and flexibility

- Help meet all current and future regulations, especially EEDI guidelines

Download

-

MAN L35/44DF CDpdf, 478 KB

-

Cruise and ferrypdf, 52839 KB

-

Four- stroke marine systemspdf, 10891 KB

-

CP propellerpdf, 4739 KB

-

Propeller & Aft Ship solutionspdf, 5365 KB

-

Turbocharger Power Systems A guide to maximum engine performancepdf, 11914 KB

-

LNG gas supply and bunker systemspdf, 767 KB

-

Optimized propulsion systemspdf, 457 KB

-

Hybrid marine propulsion systemspdf, 474 KB

Related news

-

Thursday, May 22, 2025

MAN Energy Solutions to Lead New Ammonia GenSet Project

Danish ‘NH3 Spark – FutureFlex’ project aims to develop pioneering, small-bore engine concept that dispenses with need for pilot fuel -

Tuesday, May 20, 2025

World’s Most Powerful Methanol Engine Announced

With ‘latest, remarkable milestone’, MAN Energy Solutions continues decarbonisation push -

Monday, May 19, 2025

MAN L35/44DF CD GenSet Passes Type Approval Test

Dual-fuel variants’ TAT features reduced emissions and 16% greater output than competitors -

Thursday, May 8, 2025

Offshore Vessels Feature MAN L21/31 GenSets for Diesel-Electric Propulsion

Construction of C-CSOVs trending towards China

Explore more topics

MAN Energy Solutions is now Everllence.

We have adopted a new brand name and moved to a new domain: www.everllence.com. This page will also be relocated there shortly. We are working on shifting all pages to www.everllence.com.