Custom-made machinery trains for your industry

Oil and gas recovery are highly cost-intensive businesses. Any downtime and man-hours on platforms, whether onshore or offshore, are prohibitively expensive and as an operator, you will want to keep them to a minimum. Our versatile and scalable machinery trains benefit from ultra-reliable components and the latest in digital support. Adapted for your business, they meet environmental standards and are good for your bottom line.

Mastering the machinery train

Operations in the oil and gas industry require the employment of complex machinery. Our expertise and reliable capability to supply turnkey turbomachinery trains is one of our major strengths.

The constituent parts may be various compressor types, electric motors, steam or gas turbine drives and expanders. MAN Energy Solutions supplies each constituent part and has ample experience in putting together an adapted solution for our customers. Our systems are compact, flexible and highly competitive. For your convenience, we can fully assemble and test any machinery train at our facilities. This way you can rest assured everything will be working smoothly after installation.

Our modular construction kits

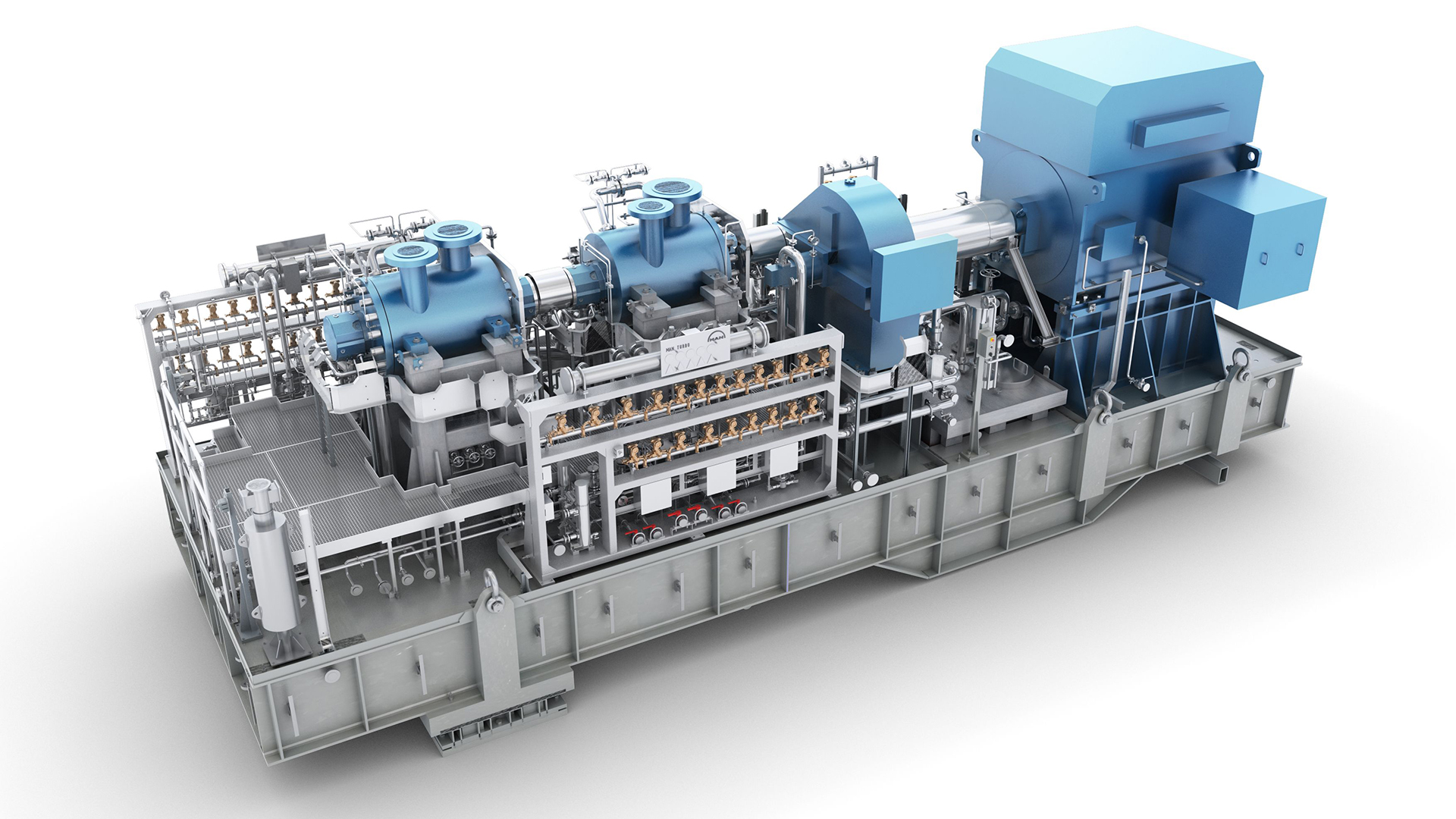

Upstream package (UPac®)

These modular trains are mainly used on floating production, storage and offloading units (FPSOs). To make the impressive delivery time of under 12 months feasible, our engineers have defined various base frame sizes which accommodate the motor, gear unit, centrifugal barrel-type compressors and accessories. These trains cover the most common output of between 1 MW to 16 MW. Far from only being used at sea, customers have ordered these trains for onshore operations, too.

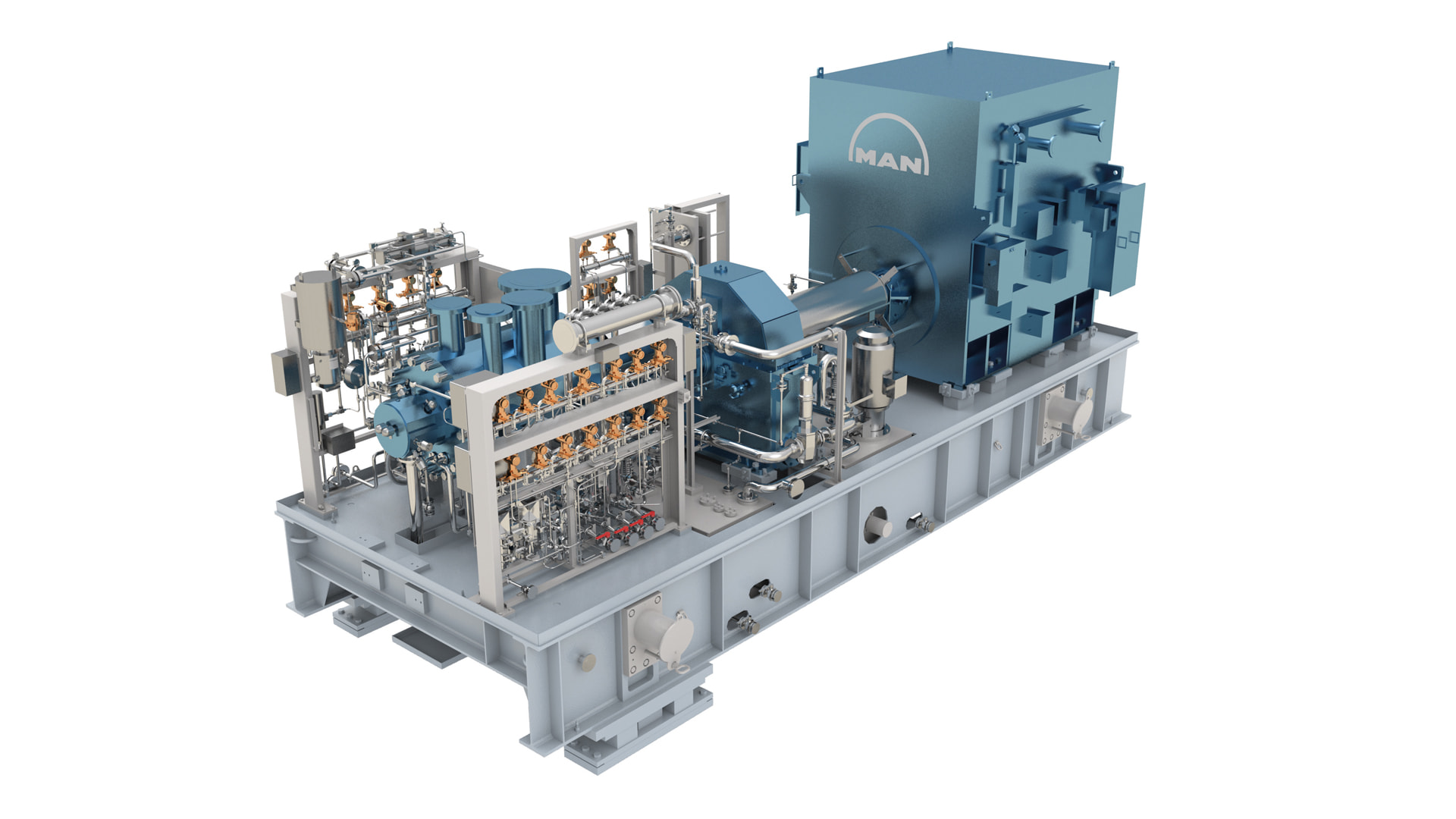

RB Compressor packages

For most applications, we offer our popular RB-type compressors in various packages, designed for your particular requirements. This significantly reduces the on-site installation time for this single-shaft, centrifugal compressor type. Packages include the RB compressor as core unit, as well as driver, gearbox (if applicable), lube oil system, seal gas rack, on skid process piping and auxiliaries. Most applications benefit from our pre-designed, time- and cost saving packages; however, we also design custom-made set ups from scratch, using our proven technology, if your products require a unique solution.

MAN PrimeServ keeps your turbomachinery running

Our service engineers provide preventive maintenance, assist your troubleshooting, and get your facilities up and running in no time – wherever and whenever you need them.

How you benefit:

- Fast, reliable and expert customer support

- Bespoke service agreements

- Global service – 24 hours a day, 365 days a year

Contact our MAN Oil & Gas support team

A great turbomachinery train at the heart of your business can make all the difference.

Talk to us to find out more about how our bespoke trains can help you cut costs, improve environmental standards and increase competitiveness.