The growing hydrogen market

Hydrogen is widely used for ammonia production in the chemical industry and for hydrotreating processes in refineries. Due to the decarbonization targets, green hydrogen shall be used in various industries to replace fossil fuels and feed stocks. MAN Energy Solutions offers a wide range of compressor types to meet the different compression requirements at each stage.

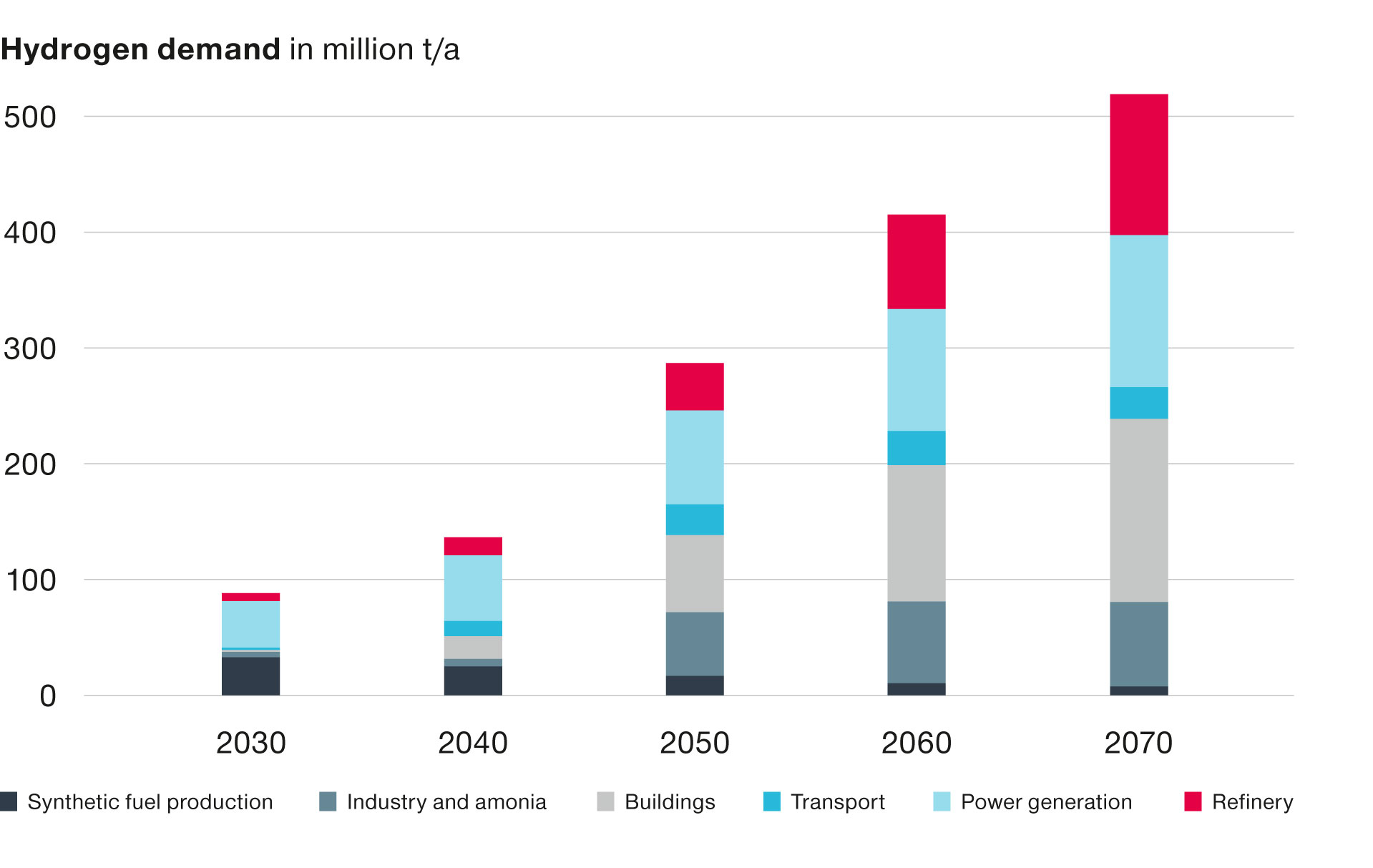

Hydrogen demand projections 2030-2070

Demand for hydrogen is growing, for example to use it as future fuel for mobility and transport, green steel production, power generation, and process and district heating.

According to the International Energy Agency, hydrogen demand is expected to increase fivefold from 2030 to 2070, with refinery as the only sector that decreases its demand.

Compressor solutions that fit your process

We tailor each compressor solution to the specific customer process and needed compression requirements. A modular design approach assures communality in components and adds overall reliability. Our expertise includes building industrial systems for large industrial plants that produce ammonia and methanol and for carbon capture.

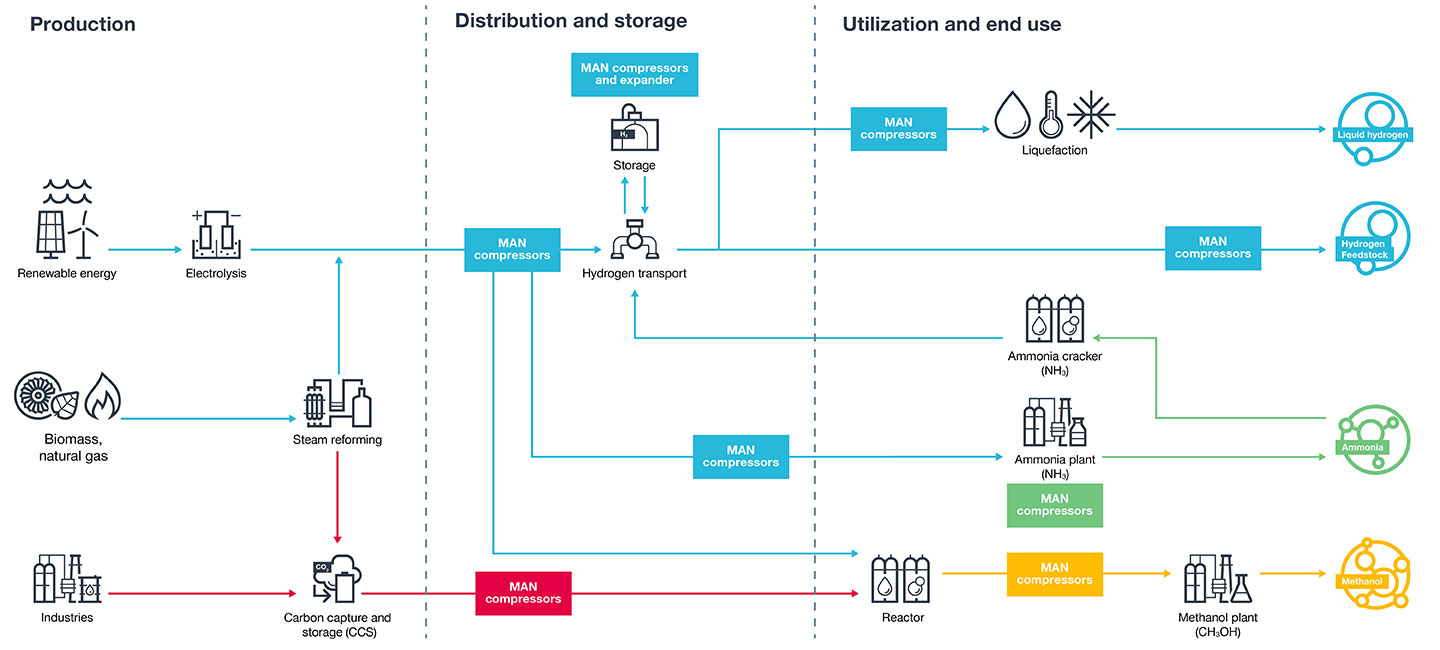

MAN compressor solutions for hydrogen related applications

Green hydrogen to be used as feedstock in the various applications and industries, it must be boosted to higher pressures after production. Only then can it be transported via pipelines and stored in salt caverns to be available 24/7 in sufficient quantities. MAN offers various compressor types to cope with the requirements of the specific application, such as actual volume flow and required compression ratio.

In the future green hydrogen shall be used for liquefaction in the mobility and transportation sector or replacing natural gas for direct reduction in the steel industry. It is also the feedstock for green ammonia plants. Green ammonia is supposed to be used as hydrogen carrier, as fuel for engines for ocean going vessels, feedstock for the fertilizer industry and as gas turbine fuel for power generation and district heating.

Together with CO2 from CCUS, hydrogen shall be used to produce syngas as feedstock for methanol plants. The methanol is used to produce synthetic fuels (synthetice kerosene, diesel and gasoline) or in the chemical industry for synplastic production. CO2 and hydrogen are also used for the Fischer-Tropsch process for producing carbon-neutral liquid hydrocarbon fuels.

Hydrogen utilization added value chain and MAN Energy Solutions Turbomchinery products

Explore the detailed Hydrogen utilization added value chain here

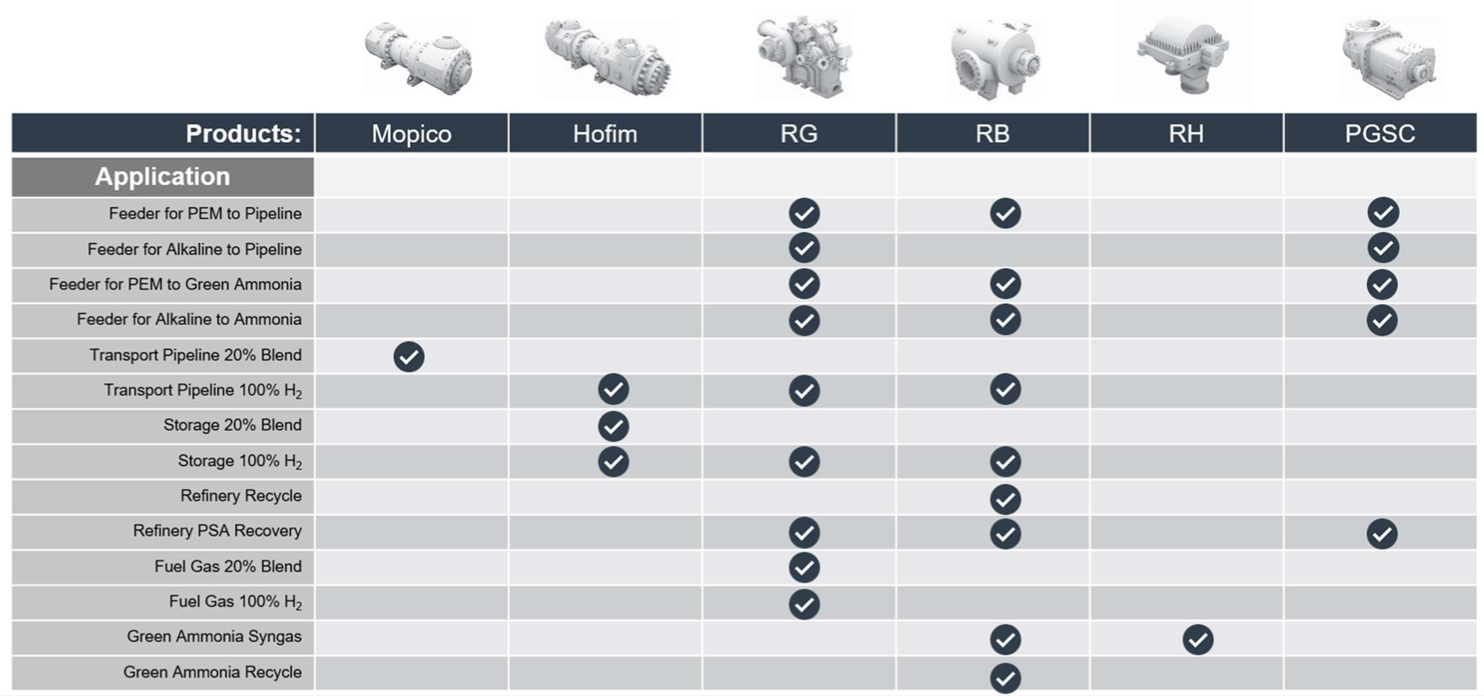

MOPICO® compression systems

These hermetically sealed motor-pipeline compressors with incorporated motor and magnetic bearings are well positioned to serve pipeline transport for hydrogen with zero emissions to the atmosphere.

Applications

- Transport pipeline 20% blend

HOFIM® compression solutions

HOFIM Compressors feature an incorporated motor, magnetic bearings, and are hermetically sealed for zero emissions. They provide highest availability (major overhaul after 9 to 10 years).

Applications

- Transport pipeline 100% hydrogen

- Storage 20% blend

- Storage 100% hydrogen

Integrally Geared Compressor (RG)

Due to their higher impeller tip speed, these compressors need fewer stages for the compression of light molecular weight and can provide a high pressure ratios per casing for 100% H2 at high pressure.

Applications

- Feeder for PEM to pipeline

- Feeder for alkaline to pipeline

- Feeder for PEM to green ammonia

- Feeder for alkaline to ammonia

- Transport pipeline 100% hydrogen

- Storage 100% hydrogen

- Refinery PSA recovery

- Fuel gas 20% blend

- Fuel gas 100% hydrogen

Process Gas Screw Compressors (PGSC)

Because they use the displacement principle, process gas screw compressors offer large pressure ratio at atmospheric suction pressure.

Applications

- Feeder for PEM to pipeline

- Feeder for alkaline to pipeline

- Feeder for PEM to green ammonia

- Feeder for alkaline to ammonia

- Refinery PSA recovery

Horizontally Split Radial Compressor (RH)

These compressors are used in large-scale green ammonia plants for the Haber-Bosch process. They offer a discharge pressure of up to 45 bara for this application.

Applications

- Green ammonia syngas

Vertically Split Radial Compressor (RB)

Vertical Split Radial Compressors, also known as Barrel Type, offer single casing flows of >300 up to 210,000 m³/h (effective).

Applications

- Feeder for PEM to pipeline

- Feeder for PEM to green ammonia

- Feeder for alkaline to ammonia

- Transport pipeline 100% hydrogen

- Storage 100% hydrogen

- Refinery recycle

- Refinery PSA recovery

- Green ammonia syngas

- Green ammonia recycle

MAN PrimeServ: Enjoy expert round-the-clock service and support worldwide, 365 days a year

MAN PrimeServ is the perfect complement to our excellent products. Our technicians are always available to answer questions, assist in troubleshooting and get your facilities up and running in no time – wherever and whenever you need them.

How you benefit:

- Fast, reliable and expert customer support

- Prompt 24-hour OEM spare part delivery

- Individual O&M contracts

- Global service – 24 hours a day, 365 days a year

Contact our experts on compressor technology

The best compressor solution for your requirements

Let our experts find the best solution for your hydrogen project by evaluating specifications such as pressure ratio, the molecular weight of your hydrogen (dry, wet or hydrogen-rich gas), and volume flow.

MAN compressors offer high reliability with low maintenance, low wear and tear, and low vibrations throughout the entire system/plant. The low weight and space requirements reduce CAPEX.

Explore more topics

MAN Energy Solutions is now Everllence.

We have adopted a new brand name and moved to a new domain: www.everllence.com. This page will also be relocated there shortly. We are working on shifting all pages to www.everllence.com.