MAN B&W ME-GI prepares your fleet for future regulations

The MAN B&W ME-GI two-stroke dual-fuel engine provides a future-proof solution for LNG/methane-powered vessels thanks to its negligible methane slip and high fuel efficiency.

Based on one of the industry’s most trusted platforms, the MAN B&W ME-GI uses a high-pressure fuel supply system and is suitable for many types of vessels. The engine achieves exceptionally low methane slip emissions and provides a large degree of flexibility for meeting emissions regulations, now and in the future. We have also refined and simplified the design, upgrading key components, and improving reliability.

The world’s most efficient engine for methane as a fuel

Perfect for new builds or retrofits, the MAN B&W ME-GI minimizes operating costs by delivering high industry-leading thermal efficiencies no matter which fuel is used. This is a huge advantage, especially for container vessels in a market with fluctuating fuel prices. The ME-GI can also be fueled with bio-methane as well as synthetic natural gas, providing a clear route towards greenhouse gas reductions.

Next-generation performance and efficiency

Key benefits

- Proven two-stroke MAN B&W engine technology

- Minimal environmental impact (low emissions thanks to negligible methane slip and reduced CO2 emissions)

- No need to compensate with liquid oil fuels to accommodate low methane numbers or high ambient temperatures

- Flexible operation using fuel oil or LNG

- Knocking is not an issue

- Supports waste heat recovery (WHR)

- Easy retrofit compared to Otto cycle engines

Low OPEX

The ME-GI is built for low OPEX, delivering the same industry-leading thermal efficiency no matter which fuel is used. This is a huge advantage in a fluctuating fuel market where LNG bunkering will become the norm. The auxiliary equipment costs have been reduced and the engine’s installation is simplified. Furthermore, key components have been updated to improve performance and deliver a more environmentally friendly solution.

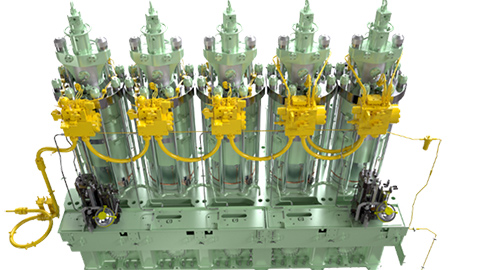

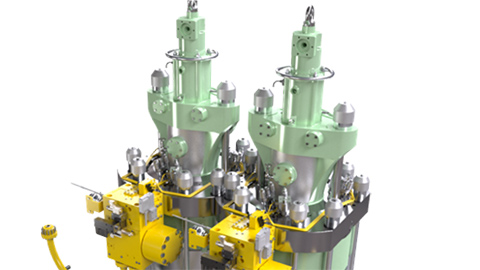

Component upgrades

The new MAN B&W ME-GI incorporates a range of key component upgrades that improve reliability, maximize efficiency and lower OPEX, helping you to stay competitive in a challenging market.

- Lowest gas consumption of any marine two-stroke engine

- Simplified piping system provides a more compact solution with fewer components, and therefore lower maintenance costs

- New gas block with an improved window valve enables cut-out of an individual cylinder operating on gas, while allowing continued operation on fuel oil

- Updated pilot oil injection system enables the pilot oil energy fraction to be lowered to just 1.5% at 100% load for L1 rated engines in certain bore sizes*

- Optional compact pump vaporizer unit features embedded redundancy (3 x 50%) and integration with the ME-GI engine control system

*Performance values indicated refer to energy fraction for L1 rated engines operating at 100% load point in Tier II mode. Actual values may vary depending on engine rating and load conditions.

Frequently asked questions

For which vessel types is the ME-GI engine especially suited?

The MAN B&W ME-GI two-stroke engine is ideal for the application on LNG carriers, PCTCs, VLCCs, tankers, container vessels, and bulk carriers.

How is a negligible methane slip on the ME-GI engines ensured?

Low methane slip on MAN B&W ME-GI two-stroke engines can be achieved due to different factors:

1. Use of the diesel cycle which ensures complete combustion due to very high combustion temperatures as well as a rich mixture

2. A high compression ratio

3. An optimal design of the combustion chamber and components

Can MAN B&W ME-GI engines be also operated on biomethane and SNG?

Biomethane has a high energy density and is affordable. Biomethane can also reduce CO2 emissions proportionately. SNG can seamlessly be phased into global gas supplies according to availability. Both, biomethane and SNG are optimally suited for the ME-GI engine.

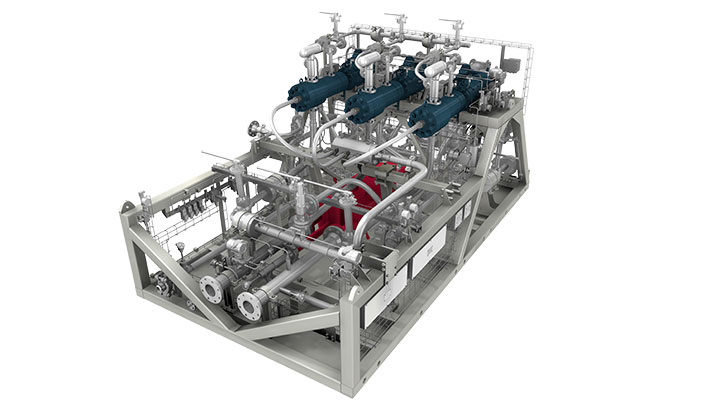

What is PVU? What function does it have in a MAN B&W ME-GI engine?

The ME-GI/GIE Pump Vaporiser Unit (PVU) is a standardized high-quality pump unit for the supply of methane to MAN B&W ME-GI engines. With its compact and intelligent design, PVU provides a lean design and integration in the fuel gas supply system (FGSS). It is highly compatible with MAN B&W ME-GI engines and supports monitoring by PrimeServ Assist.

Service solutions for optimum cost efficiency of your MAN B&W ME-GI engine

Explore your options for the MAN B&W ME-GI

The new MAN B&W ME-GI two-stroke dual-fuel engine is built to support your power needs today and for the future.

Continue reading

Related products

-

Four-stroke small-bore engines

With our small-bore engines, you are prepared for whatever lies ahead.

-

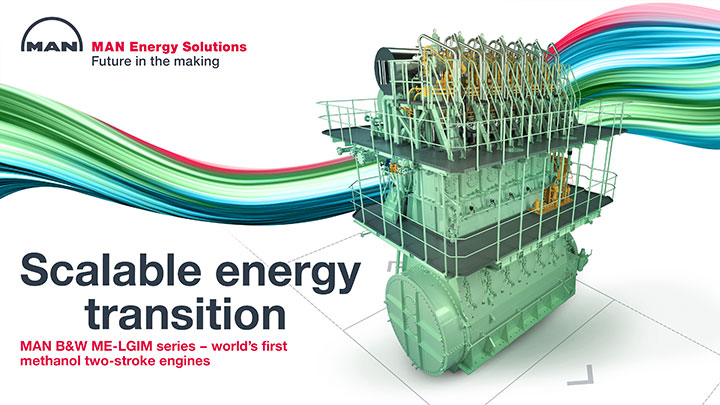

MAN B&W ME-LGIM

The MAN B&W ME-LGIM is a two-stroke, dual fuel engine that runs on both methanol and conventional fuels.

-

Pump Vaporiser Unit (PVU)

The ME-GI/GIE Pump Vaporiser Unit (PVU) is a standardized high-quality pump unit for supply of LNG or ethane to MAN B&W two-stroke ME-GI/GIE engines.

Related news

Methane-fuelled MAN B&W ME-GI two-stroke engine

The MAN B&W ME-GI has been in service for more than a decade already, and with a continuous focus on optimizing the engine design, it remains a preferred choice across vessel segments and sizes.

Watch the recording of our two-stroke MAN ExpertTalk where we take a closer look at the new 10.7 engine platform, the improved gas return system, and general engine availability.

MAN Energy Solutions is now Everllence.

We have adopted a new brand name and moved to a new domain: www.everllence.com. This page will also be relocated there shortly. We are working on shifting all pages to www.everllence.com.