Naval propellers – high-performance solutions

Reliable systems tailored to tough demands

Characteristics of our naval propellers

Specialized navy specifications are crucial. Our customized propeller solutions can cater to higher cavitation inception speeds, possible shock impacts, and mission-critical conditions requiring additional redundancy, silent operation with minimal hydro-acoustic signatures, and suppressed underwater-radiated noise.

CPPs, FPPs and bolted adjustable

Our naval propeller portfolio – ranging from controllable pitch propellers (CPPs), fixed pitch monoblock propellers (FPPs), and FPPs with replaceable blades, to adjustable bolted designs with tailored blade configurations – offers excellent coverage of navies’ propulsive performance and reliability demands.

Nowadays a wide range of naval and patrol vessels are powered and propelled by MAN Alpha propeller and aft ship solutions – ranging from powerful combat frigates, flexible command support vessels, special minehunters, and ice-breaking offshore patrol vessels to robust shallow-draft coastal supply cutters.

Global approach – shafting and control systems

Optimization and shock excitation

The mechanical and hydrodynamic design optimization of propeller shaft strut arrangements is one example of a key parameter for aft ship elements. CFD calculations and model tests confirm that propeller performance and strut designs are closely interlinked.

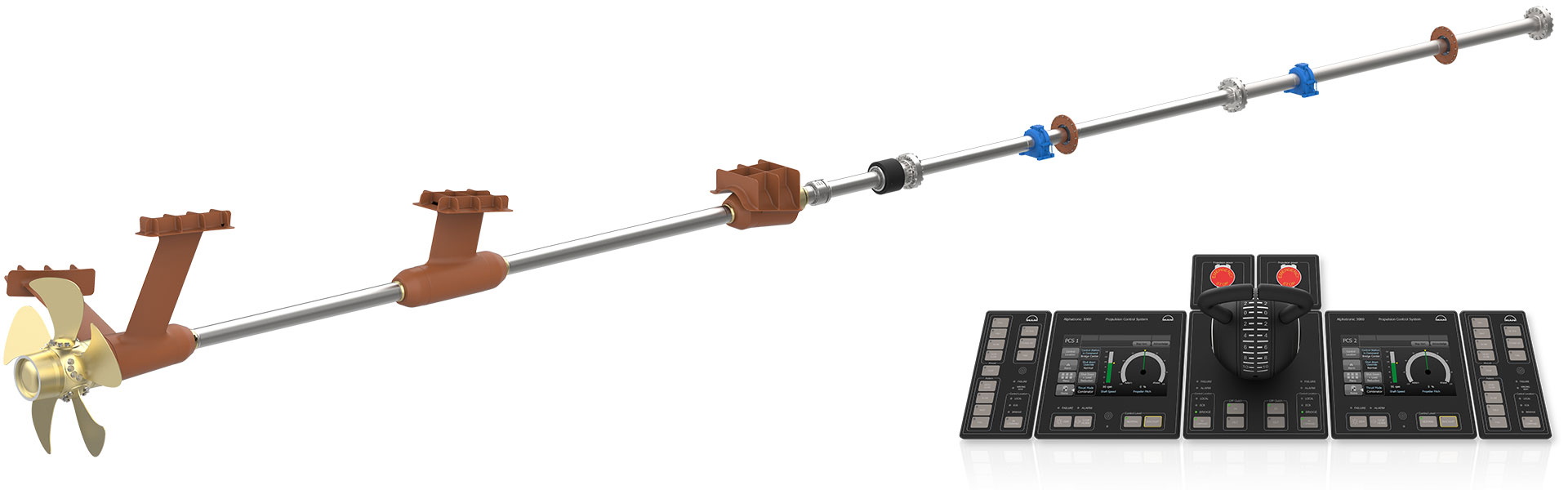

Shock requirements can be considered in the design for which, as an example, our global approach goes all the way and includes the Alphatronic propulsion control system. Here, shock load tests are performed with certification for panels passing 10 G in 10 ms, cabinets 20 G, and sensors (pitch feedback, tacho) up to 320 G in 3.3 ms.

Your benefits on the right course

- Best propulsive performance: Cutting-edge hydrodynamic blade/hub/strut designs as the basis for top propulsion performance and versatility in diverse operating missions

- Fuel savings and reduced emission levels: High propulsive efficiency equals low fuel consumption and fewer exhaust gas emissions

- Reduced hydro-acoustics: Maximized propeller efficiency design – targeted with due respect to required mitigation of cavitation, pressure pulses, and noise

- Shock resistance: System solutions can be designed and documented to shock requirements and military standards – from propellers and shafting to propulsion controls

- Lowest total cost of ownership: Robust and reliable materials and components – designed with ample margins of strength, ensuring minimal consumptions, low wear rates, and a long and safe service life

Learn more from our Expert brochures and ExpertTalks

Underwater Radiated Noise

Naval propellers - 40 page brochure

Insights into naval propeller solutions

System solution and scope of supply example

Get an overview of our propeller and aft ship offering: Take a quick journey along the shaftline of a full feathering CP propeller and aft ship system with major components and options presented. A final optimized propeller design and blade number integrates e.g. with strut bracket angles, bracket profiles and position for a best possible wakefield for the propeller.

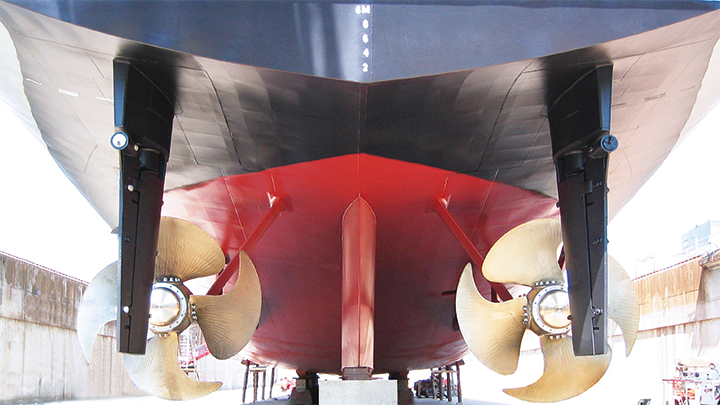

OPV – arctic operation

For operation in ice, our CPPs and bolted FPPs can be delivered up to the highest polar ice classes. The CPP equipment propelling the Offshore Patrol Vessel ‘P571 Ejnar Mikkelsen’ is designed in line with ice class DNV/GL Ice 1A. The propulsion power is delivered by two MAN 8L27/38 engines with a twin-in/single-out gearbox configuration.

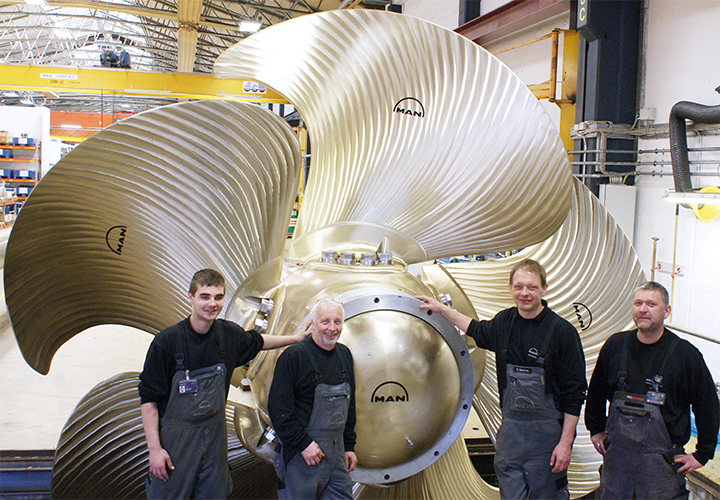

Large CP propeller type VBS 2150

With a propeller diameter of 7.6 meter, the VBS 2150 propeller system is the so far largest MAN Alpha design. The hub weighs 36 ton and on top shall be added the five blades weighing 26 ton, thus in total 62 ton. Complete with shafting the finished CP propeller system assembly comes to a weight of approx. 200 ton.

Explore our propeller solutions

FPP

The FPP designs effectively cover MAN Energy Solutions' engine portfolio. The propeller series are available in 3-, 4-, 5-, and 6-bladed monoblock configurations. For high ice classes, bolted blade designs can be offered.

CPP

The CPP designs effectively cover a power range up to 50,000 kW per shaft line. With no less than 23 different hub sizes, a cost- and performance-optimized solution is always offered. 3-, 4- and 5-bladed configurations are available.

General information on our CPPsDo you need more background information on ship propulsion in general?

MAN PrimeServ propeller maintenance concept

Our propeller maintenance concept (PMC) service packages for propeller maintenance are offered in connection with five- and/or ten-year inspections – in accordance with the docking periods recommended by the classification societies.

How you benefit

- Prompt delivery of high-demand spare parts within 24 hours

- Fast, reliable and competent customer support

- Individually tailored O&M contracts

- Ongoing training and qualification of operators and maintenance staff

- Global service, 24 hours a day, 365 days a year

Looking for a naval design propeller and aft ship solution?

Let us present what may be under the waterline – by tailoring the ideal solution for you. Get in touch today – and propel ahead.

Related news

-

Wednesday, February 10, 2021

Abeking & Rasmussen Order Complete MAN 175D Hybrid-Propulsion Packages for Indonesian Navy Minehunters

Naval order for versatile MAN 175D engine -

Thursday, October 29, 2020

MAN 16V175D Propulsion Packages for Israel Shipyards

Israel Shipyards chooses dual MAN 175D units for OPV-45 design