Petrochemicals – the modern world’s feedstock

Serving both fuels and basic chemicals, the petrochemical industry has always been the driver of industrialization and modern life as we know it. MAN Energy Solutions helps to safely and reliably operate plants while mastering the transition to a hydrogen-based era.

Fueling everday life

Shortest downtimes determine economic viability of an industry

Petrochemical feedstocks are major assets of modern everyday life. Whether polymers and plastics, detergents and cleaning agents or pharmaceutical intermediates – the petrochemical industry is the foundation of numerous essential products. The reliable and continuous operation of petrochemical plants is crucial to ensuring profitable production in a challenging market environment. At the same time, growing safety requirements must be met. Reducing downtime to a minimum can only be achieved by a turnaround provider with a proven track record, experienced personnel and single-source engineering and fabrication capabilities.

Enabling efficient and reliable production

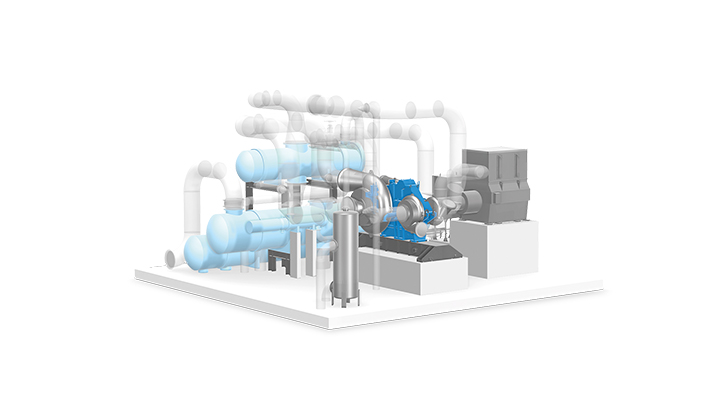

MAN Energy Solutions has supplied compressors, gas and steam turbines, reactors, RFCC/FCC components and furnaces to petrochemical sites all over the world. Our broad expertise, longstanding experience and understanding of our customers’ demands are prerequisites for enabling low operating costs. This is because we support reliable, efficient and safe production processes with our turbomachinery as well as our reactors.

Heat pumps

The petrochemical industry can use heat pumps to reduce CO2 emissions and heating costs. Heat pumps extract heat from low temperature sources such as water, air, or waste heat from machinery and amplify it to higher temperatures. When powered by renewable electricity, heat pumps can supply carbon-neutral heating or cooling. We scale our solutions to your temperature and power needs.

More on heat pumps

CCUS

Petrochemical plants emit large amounts of CO2 in the form of flue gases. This CO2 can be captured by amine treatment, cryogenic capture or pressure swing adsorption. It can then be purified, compressed, and transported to facilities that use it to make synthetic fuels, beverages, dry ice, or chemicals. CO2 can also be stored permanently in geologically secure reservoirs. MAN DWE supplies the technology for the compression and liquefaction of CO2, as well as for heat recovery and heat integration at your plant.

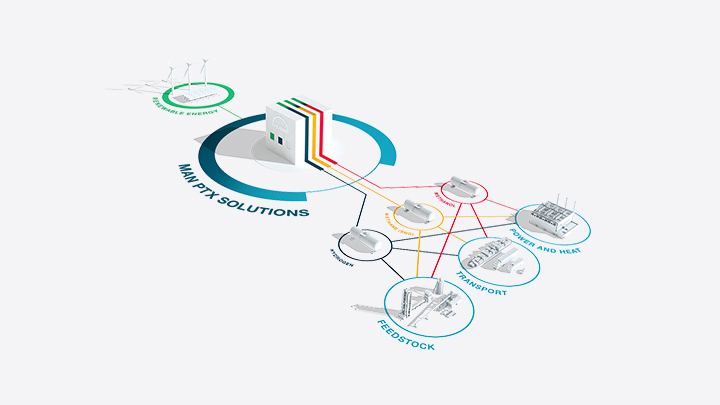

More on carbon capturePower-to-X (PtX)

PtX processes include:

PtX processes include:

- Power-to-Gas (PtG)

- Power-to-Liquid (PtL)

PtX processes are used for the production of:

- E-methanol (CH3OH)

- Synthetic fuels

- Synthetic natural gas (SNG), renewable methane

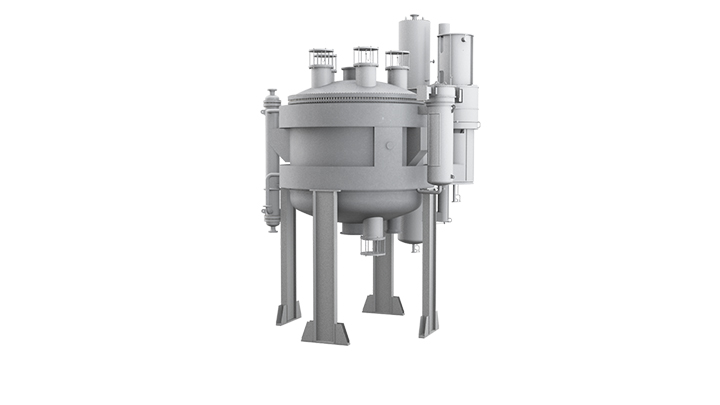

DWE reactors

MAN DWE supplies key components for virtually every application in refineries and the petrochemical industry. Our turnaround (TAR) and shutdown engineering capabilities have been proven all over the world. We provide residue fluid catalytic cracking and fluid catalytic cracking units including reactor and regenerator, pipework, pressure-retaining spare parts, combustor risers and other components. We also offer waste heat recovery units for methanol plants and high-pressure equipment. We are experienced in working with high-temperature chromium steel and can design custom pressure equipment.

More on DWE reactorsFind out which products and solutions fit your requirements

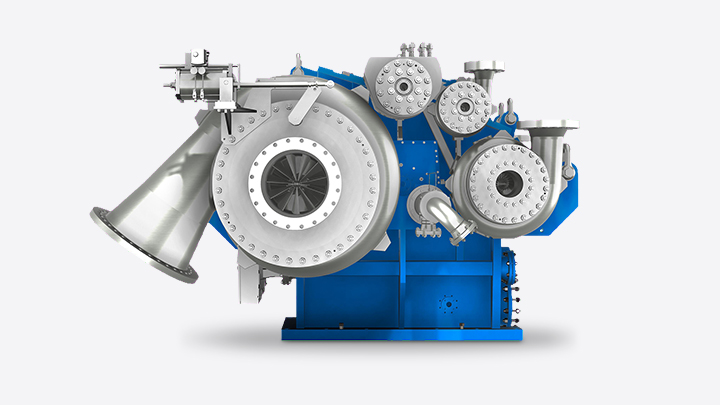

Compressors manufactured by MAN Energy Solutions sit at the heart of many petrochemical processes. Highly reliable, they need little maintenance and ensure minimal downtime. They are renowned worldwide for their quality as well as their high efficiency. They comply with all regulations and enable a solid return on investment.

Water-, gas- and oil-reactors produce:

- Gas-to-liquid, GTL and other Fischer-Tropsch related products (BTL, CTL)

Salt-operated reactors:

Fixed-bed tubular reactors for heterogeneously catalysed reactions.

- Tubular reactors up to 60,000 tubes

- Custom made

- Multi-stage reactors, sector design, containment design

- Temperature 300-550°C

- Heat removal total rate up to 65 MW

Developing your process: from first steps to large reactors

Depending on your process requirements, we select the reactor type which will provide the best results. We make sure the size fits your site and that you will enjoy maximum yield with minimum waste. We also focus on the safety of your operations and on your overall ROI.

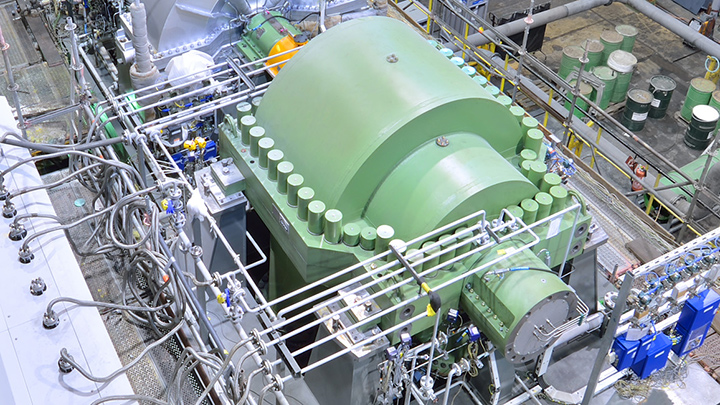

Compressors for the petrochemical industry

PDH plant

| Country: | UAE |

| Year completed: | 2015 |

| Duty: | Heat pump |

| Scope: | 1x centrifugal compressor RH80-7 |

| Driver: | Steam turbine, MST080 |

MAN Heat pumps for industrial processes

Take part in our MAN ExpertTalks and find out how broad our product portfolio of heat pumps for industrial processes is, in which projects MAN heat pumps are already being used and get the latest market insights from our experts. We look forward to your participation!

Download

-

Heat pumps for process industriespdf, 2130 KB

Are you producing petrochemicals? Are you looking for cutting-edge equipment?

Whatever petrochemical you are working with, our compressors, reactors, RFCC/FCC components, furnaces and steam turbines will not let you down. Find out how we can support your production process.

MAN Energy Solutions is now Everllence.

We have adopted a new brand name and moved to a new domain: www.everllence.com. This page will also be relocated there shortly. We are working on shifting all pages to www.everllence.com.