Process screw compressors

Oil-free screw compressors

MAN screw compressors are designed, manufactured, and tailored to your process needs at our site in Oberhausen, Germany. The oil-free technology minimizes maintenance needs and ensures the process gas is not contaminated by lubricating oil.

High performance: first choice for challenging gases

We offer a range of screw compressors for volume flows from around 200 m3/h to 100,000 m3/h at up to 52 bar. This allows for high pressure ratios and effective temperature control, making them suitable for critical applications where failure is not an option.

These high compression ratios even work with gases of low molecular weight and are thus ideal for hydrogen from electrolyzers as well as gases with changing molecular weight.

A further strength is the reliable handling of heavy hydrocarbons with significant impurities such as dust, particles, or liquids.

Clean and robust: the advantages of screw compressors

Screw compressors combine the advantages of centrifugal and reciprocating compressors, operating as positive displacement machines with rotating parts only.

Benefits include long maintenance intervals, short downtimes, and low operating costs. Robust MAN oil-free screw compressors can handle even the most challenging gases during many years of uninterrupted operation.

Multiple applications: hydrogen, offshore, process industry

MAN oil-free screw compressors support critical processes across multiple sectors. Safe operation and exceptional reliability eliminate the need for backup machines, making them a versatile solution for complex process gas compression:

- Hydrogen compression (electrolyzers, pressure swing absorption)

- Vapor recovery (offshore & onshore)

- Flare gas recovery

- Soda ash

- Butadiene

- Acetylene

- Styrene monomer

- Aniline

- Boil off

- Blast furnace gas

- Coke oven gas

Screw compressor references

Hydrogen

Demand for hydrogen is rising, but compressing this low-density gas is challenging. MAN Energy Solutions has more than 50 years of expertise in hydrogen compression. For electrolyzers up to 300 MW, the flow can be handled by a single compressor unit bringing the hydrogen from atmospheric pressure to approximately 16 bar.

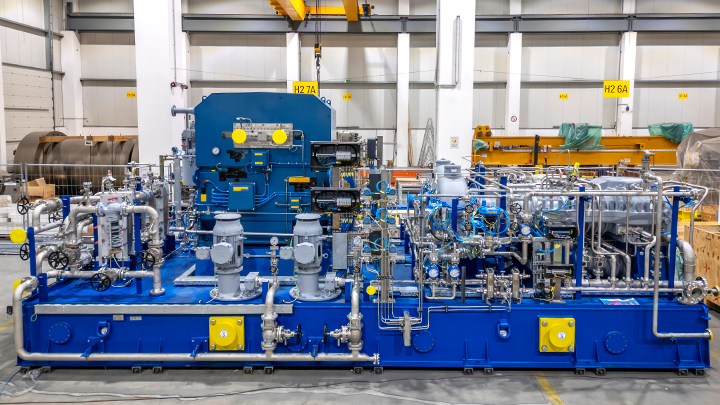

Country | France |

| Year completed | 2025 |

| Duty | Electrolyzer feeder H2 compression |

| Type | SKUEL 408, CP 200 |

| Scope | 4 units |

| Driver | Electric motor |

| Key feature | Special sealing technology |

Offshore

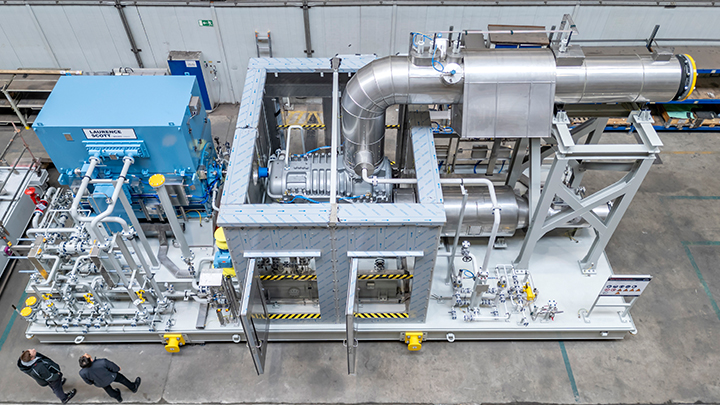

MAN Energy Solutions provides a range of single-lift skids for use on offshore platforms and FPSO vessels. For Vapor Recovery Unit (VRU) or as Flash Gas Compressor, screw compressors are the right solution. The efficient footprint of the packages and the single-lift design are decisive advantages in offshore operation. The units are packaged as complete modules to suit your project’s requirements.

Country | Angola |

| Year completed | 2024 |

| Duty | Hydrocarbon vapor recovery |

| Type | SKUEL 510 |

| Scope | 2 units |

| Driver | Electric motor |

| Key feature | Single-lift package |

Chemical industry

Heavy-duty industries require high-performance compressors. MAN Energy Solutions' process gas screw compressors are designed for demanding applications such as butadiene extraction, styrene monomer production, hydrogen purification, soda ash manufacturing, and steel production (including blast furnace and coke oven gas). They also play a crucial role in the handling of gases like acetylene.

Country | Worldwide |

Year | Since 1954 |

| Duty | Various chemical applications |

| Type | Process screw compressors |

| Scope | SKUEL and CP series |

| Driver | Electric motor and steam turbine |

| Key feature | Handling corrosive and dusty gases |

Continue reading

Ready for your challenges

Handling process gases is a fascinating technical challenge. If you are looking for a cost-effective and long-lasting compressor, get in touch with our experts directly. Our experienced team will accompany you through all phases of the project, from initial concept planning to professional order processing and all the way to successful plant operation.