Turbomachinery repairs

Assure the availability of your equipment outside of scheduled shutdowns

A transparent process in planning overhauls, repairs or modifications of turbomachinery is crucial to understanding the requirements of a project and completing the work on time and without delay to your business and your process. This is why close communication with you is as important to us as delivering a full range of flexible high-quality services that ensure the business efficiency and reliability of your plant.

Rapid response, expert cause analysis, and high-quality repair measures that help protect your business

Leverage our OEM expertise, decades of experience and excellence in implementation to resolve issues that impact the performance of your equipment

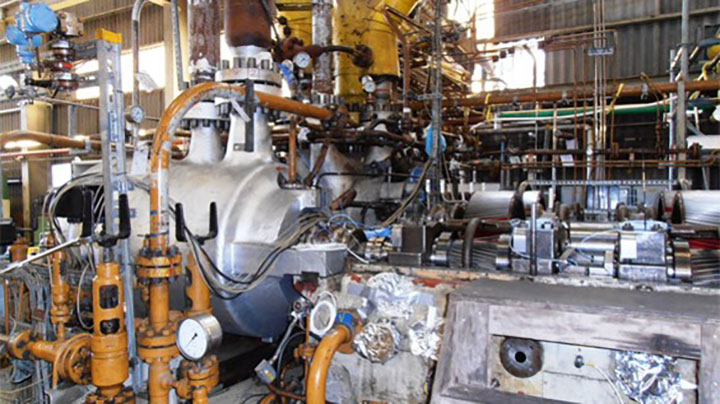

MAN PrimeServ’s full range of repair services, from overhauls and modifications to complex repairs, are available, both on-site through our field service teams and off-site at MAN PrimeServ service workshops around the world. Consulting engineers and veteran field service experts conduct inspections and root cause analyses to define the exact scope of repairs. Our service workshops use cutting-edge technologies, such as laser welding, 3D measurement and remanufacture. Laboratories are available for material testing and state-of-the-art test stands for test runs after repairs. Through our repair services, you have access to the latest design iterations of OEM-quality parts as well as our part services, from customization to remanufacture.

Get the most out of downtime for repair

Repairs present an opportunity to optimize equipment – an approach that makes good business sense. We can fit most optimizations into repair and overhaul projects – without impacting the mean time to repair. Not to forget, the cost of optimization is lower when included in a project such as repairs. Some optimizations add to your competitive edge, such as improvements to efficiency levels and reliability; others extend the service life of your equipment by boosting corrosion resistance and fatigue strength. Benefit from our OEM expertise and our intimate understanding of your machinery.

How you benefit:

- Comprehensive support from a single source

- Tailor concepts to the needs of your operations

- Leverage advanced technologies

- Fast response times and a global service network

The MAN PrimeServ portfolio of repair services

MAN PrimeServ is the service solution provider for the entire

MAN Energy Solutions portfolio as well as third-party rotating equipment.

We offer you a full spectrum of services, solutions, and technologies that give you access to higher availability, efficiency, and capacity.

- Maintenance, inspection, and repair

- On-site recovery

- Consultancy on how to maximize the cost efficiency of your repair process

- Evaluation of remaining lifetime potential

- Testing facilities

- Accredited material testing laboratory

- Next-generation technologies for maintenance, repair and analysis

References

Repair of Axial-Compressor after incident

Repair of Axial-Compressor after incident

Workshop Zurich

Findings:

- Severe damaged rotor blades and stator vanes

- Cracks found in two blade grooves of shaft during blade dismantling

Measures

- Repair of stator including new and refurbished vanes

- Repair of rotor including new and refurbished blades, two blades rows with enlarged root design to fit the reworked blade grooves

Challenge:

- Shorten lead time as much as possible to replace already emergency repaired rotor and stator which were in operation with a reduced possible operating range

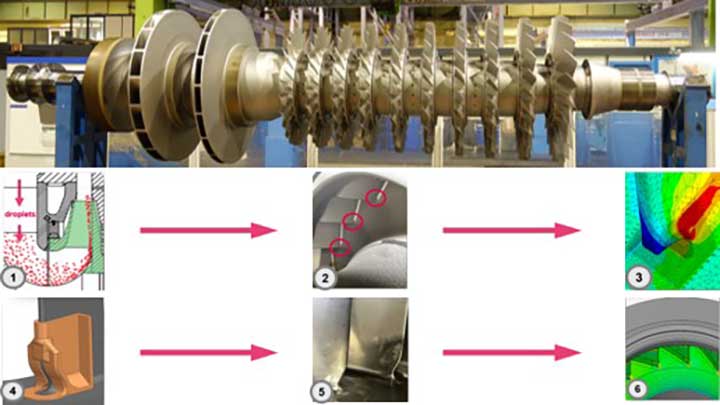

Special tailor made repair of Axial-Compressor

Special tailor made repair of Axial-Compressor

Workshop Oberhausen

Incident:

- 1 heavily intercooler leakage

- 2 erosion damage at blade edge / impeller disc

MAN PrimeServ Solution

-

3 analysis of the actual stresses via FEM

Result: not safe for use. Re-design of blade contour -

4 CAD Design and 3D-Print of grinding-template

-

5 performed grinding and NDT

-

6 verification with CAD contour ready for HSB and reuse

Task:

-

Repair / make ready for installation under emergency condition

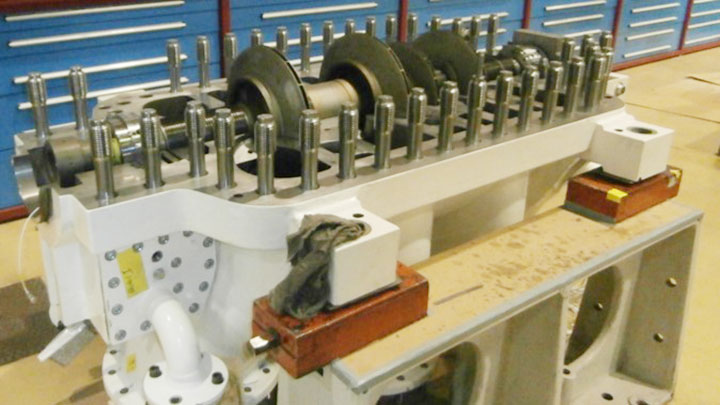

Crash-Repair of Axial-Compressor

Crash-Repair of Axial-Compressor

Workshop Oberhausen

Incident: Fire damage

- Broken rotor blades

- Plastic deformation on the guide blades

- Spare rotor was not available

MAN PrimeServ Solution

-

Machine the existing rotating blades

-

Grind the bearing points

-

Renew all sealing strips, frequency measurements

-

HSB

-

Manufacture a new stage 2 guide ring

-

Completely repair guide blade carrier

Task:

-

Emergency repair of the rotor

-

Emergency repair of the guide blade carrier (temporary solution)

Repair of chlorine compressor

Repair of chlorine compressor

Workshop Berlin

Incident: Workshop overhaul

MAN PrimeServ Solution

- Inspection and repair of compressor in the Workshop Berlin

- Inspection and repair of main and spare rotor

- Renew and retrofit inner compressor parts

- Repair and pressure test of compressor casing

- Retrofit radial tilting pad bearings

- Retrofit bearing temperature and shaft vibration monitoring

- Workshop assembly of compressor

Task:

- Overhaul of complete compressor

- Retrofit compressor monitoring

Crash-Repair of Expander

Crash-Repair of Expander

Workshop Oberhausen

Incident:

- The upper part of the housing could not be disassembled at Site

MAN PrimeServ Solution

-

Transport of the complete expander to the workshop Oberhausen

-

Opening the housing by using special mounting devices

-

Complete rotor findings

-

Carrying out extensive repair work, e.g. thermal straightening of some components, renewal of connecting elements, repair of the adjustable inlet guide vanes …

-

Assembly of the complete expander

Task:

-

Emergency repair

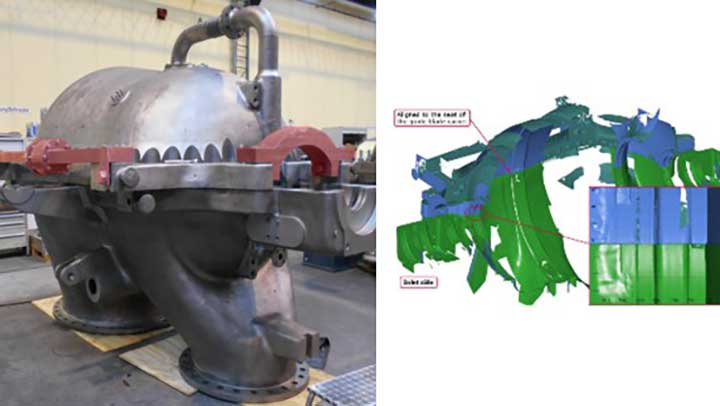

Straightening of an bended Expander Guide vane carrier

Straightening of an bended Expander Guide vane carrier

Workshop Oberhausen

Incident:

- heavily bended guide blade carrier

- spare parts are not available

MAN PrimeServ Solution

- capture current contour via 3D-scan

- thermal straightening

- 2nd Check via 3D-scan

-

2nd thermal straightening

… until all measurements are within tolerance

Task:

- Repair / make ready for installation

Repair of radial carbon dioxide compressor

Repair of radial carbon dioxide compressor with manual washing system

Workshop Ravensburg

Compressor competence / BCC:

- Repair & Overhaul project

Machine type: BBC

Application: Ammonia production

Overhaul / Repair of Compressors & Multi-stage gear Box

- Overhaul of compressor stage 1 – 4 at site and in the Workshop Ravensburg

- Overhaul of multi-stage gear box

- Partly new gear set (75%)

- New BBC couplings

- Retrofit of IGV

- Erection & commissioning

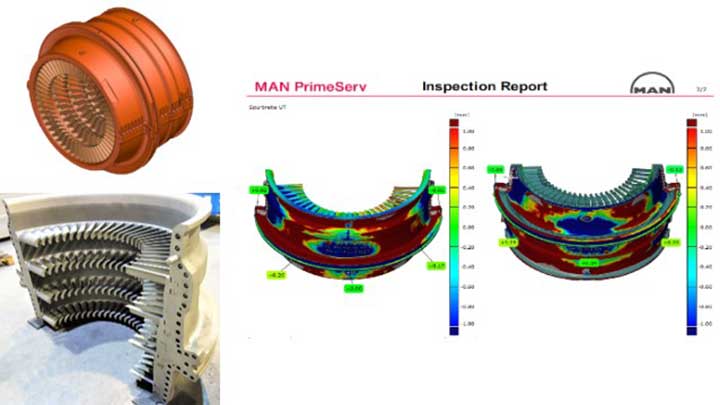

Crash-Repair of Steam-Turbine-Rotor

Crash-Repair of Steam-Turbine-Rotor

Workshop Oberhausen

Situation: Changed mode to turbine operation

-

Necessary replacement of rotating blades Stage 201

-

Customer has no spare rotor

MAN PrimeServ Solution

-

Manufacture of rotor blades before receipt of Rotor in Oberhausen

-

Replacement of rotor blades stage 201 within 17 days after receipt of rotor, incl. HSB

Task:

-

Total delivery time: Three months Incl. Blade manufacturing

-

Replace stage 201 of rotor-blades under emergency conditions

Continue reading

MAN Energy Solutions products

A power plant turning waste into heat and carbon-efficient electricity

MAN PrimeServ repaired the massive start-up damage to a customer’s steam turbine in a record time of five months. The repair team cut the time-to-repair normally required for damage of this magnitude by over 30 percent, earning them praise from the customer for their “commitment and high levels of professionalism”.

| Customer type: | Power generation |

| Application: | Waste-to-energy plant |

| Rated power output: | 80 MW |

Work scope of MAN PrimeServ: | Refurbishment of the steam turbine rotor and assembly of twelve rotor blades. Refurbishment of five guide vane carriers, which involved manufacturing and assembly of 34 guide vane stages |

Contact us

Minimize time to repair, maximize availability

MAN PrimeServ provides repair services whenever and wherever you need them. Our goals are to keep your equipment operational, shutdowns short, and maintenance costs low. For your operational certainty, we also keep expert teams on standby – to ensure you have quick and expert assistance in case of an unscheduled shutdown.

Explore more topics

MAN Energy Solutions is now Everllence.

We have adopted a new brand name and moved to a new domain: www.everllence.com. This page will also be relocated there shortly. We are working on shifting all pages to www.everllence.com.