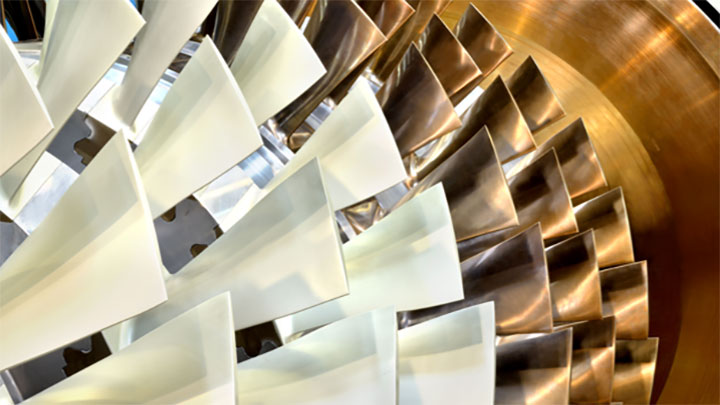

Revamps and modifications for compressors and turbines

Realign your rotating equipment with your business goals

MAN PrimeServ offers both the consultancy and the technical services you need to achieve plant targets – whether you want to boost plant availability, efficiency, capacity, and the service life of your turbomachinery, or adapt it to new process parameters or advances in process technology. Business goals and market demands evolve over the long service life of your turbomachinery. Revamps and modifications enable you to realign the behavior of equipment with your goals. Updating machinery can offer solid financial advantages over new installations.

Revitalize your rotating equipment

Leverage our experience and expertise as a trusted OEM partner and machinery manufacturer to keep equipment up to date and maintain your competitive edge.

You may want to expand the production capacity of your plant, increase plant availability, or need to lower emissions and energy consumption.

At MAN PrimeServ, we take a holistic approach to updating equipment. For support with decision-making, consulting engineers

analyze your process and conduct feasibility studies, highlighting your best options to achieve your plant targets. Modifications are based on your exact needs, replacing – or updating – only what’s unsuitable for your new process or goal.

Revamp

concepts are not limited to the core machine itself but consider ancillary systems, instruments, and controls as well.

We can also help plant operators move ahead with the digital transformation of their operations. Control system upgrades, enhanced machine monitoring and machine diagnostics are among the options available.

At MAN PrimeServ, qualified service engineers optimize the reliability, availability, safety, efficiency and environmental sustainability of your industrial compressors, turbines and expanders.

How you benefit:

- Add to your competitive edge with a comprehensive modernization

- Opt for OEM-quality services on-site or at one of our 100 service workshops

- Lower emissions

- Improve efficiency

- Boost reliability and availability

- Extend the service life of your equipment

The MAN PrimeServ revamp and modification portfolio

MAN PrimeServ is the service solution provider brand for the entire

MAN Energy Solutions portfolio as well as third-party rotating equipment. We offer you a full spectrum of solutions, and technologies for revamps and modifications, enhancing availability, efficiency, sustainability, safety, and capacity.

- Mechanical modifications

- Modification of ancillary systems

- Control system upgrades

- Revamp to facilitate optimum operation and efficiency or increase output

- Improvement of safety

- Engineering studies and consulting

Download product information

Increase availability, improve safety, strengthen sustainability, and boost capacity and efficiency of your turbomachinery: identify the upgrade solutions matching to your operational priorities, download product information, and make more informed decisions driving your overall business strategy. Explore where our upgrade solutions can take you!

References

Footprint: Off-gas expander

Location: Thailand

Year: 2018

Challenge

-

Implementation of new a new machine with reduced downtime to the minimum

Scope of supply

-

Replacement of older MAN machine

-

Supply of two-stage integrally geared expande

-

Installed on base frame, ready cabled and wired

-

Installation and commissioning

-

Adaptation/retrofitting of existing control system

Operational: Safety analysis

Location: Germany

Year: 2017

Challenge

- Compliance with new regulations & requirements

Scope of supply

-

On-site assessment of as-is condition of complete machinery train

-

Risk evaluation with regard to requirements of Machinery Directive and current norms/standards

-

SIL analysis

Solution:

-

Engineering report with specific measures to improve safety and reliability

Operational: Tip timing monitoring

Location: Norway

Year: 2019

Challenge

-

Recurring blade damages

Scope of supply

-

New guide blade carrier incl. monitoring system for axial compressor

- Online monitoring of blade deflections/crack indications

- Trend evaluation to determine remaining blade life

Operational: Redundant valve positioner

Location: Oman

Year: 2016

Challenge

-

Request for improved machine availability

Scope of supply

-

Replacement of a single channel valve positioner by a redundant valve positioner system

-

Installation and commissioning in <5 days

- Increased availability due to fully redundant system for live steam control valve

Continue reading

Get more life out of your assets

From expert requirement analysis to meticulous implementation, MAN PrimeServ’s expert teams tailor revamps and modifications to the needs of your plant. Benefit from our OEM expertise and our ongoing research and development: Our services give you access to the cutting-edge designs of parts and components.

Explore more topics

MAN Energy Solutions is now Everllence.

We have adopted a new brand name and moved to a new domain: www.everllence.com. This page will also be relocated there shortly. We are working on shifting all pages to www.everllence.com.