The power of green hydrogen

Hydrogen is a key element in the energy transition. It has the potential to decarbonize a vast variety of sectors, from shipping, heating and cooling to industrial applications. We at MAN Energy Solutions acknowledge the power of H2 and with our solutions and services, we are already covering all parts of the hydrogen economy today.

Prepared for change with the complete value chain of H2 and synthetic fuels

To reach carbon-neutrality in this generation, the world needs quick and efficient solutions. As a solution provider and general advisor on the question of decarbonization, we are ready to support the energy transition with full power. Our portfolio already covers the complete value chain of H2 from production to utilization – we are prepared for change.

Hydrogen can be produced from renewable energy in a climate-neutral way and forms the basis for the production of a variety of synthetic fuels through Power-to-X processes. We urgently need these alternative fuels to implement the energy transition, because they make renewable energy usable outside the electricity grids. In this way, CO2 emissions can also be reduced in those areas where direct electrification is not sensible or possible, such as international shipping. Hydrogen and Power-to-X thus form an important link for the sector coupling of power and heat generation, transport and industrial applications.Paving the way for a greener future

The production of hydrogen is the crucial first step in the value chain. H-TEC SYSTEMS, a German electrolysis-specialist, has been perfecting its technology for more than 20 years; MAN Energy Solutions recently acquired 99% of the company’s shares. H-TEC SYSTEMS offers PEM (Proton Exchange Membrane) electrolysers in the 225 kW to 1 MW range.

Together with MAN Energy Solutions, the company is now promoting the development of PEM electrolysers in the multi-megawatt range, which will also enable the use of the most pioneering electrolysers on an industrial scale.

Delivering a green future

To make CO2-neutral energy useful across all sectors, converting renewable electricity into storable and easy-to-handle fuels is crucial; the power-to-X process allows for just that. It is a transformation technology that converts renewable electricity into carbon-neutral, synthetic fuels, which can then be used in other sectors or be stored until needed. Among others, these fuels include synthetic natural gas (SNG), green ammonia and methanol.

MAN Energy Solutions is already a pioneer of power-to-X technology: in 2013, we commissioned the methanation reactor for Europe's first – and, at 6 MW, largest – power-to-gas plant. Currently, the e-gas plant in Werlte, Lower Saxony, supplies 1,500 gas-powered vehicles with climate-neutral fuel every year.

We have since consistently developed power-to-X technology and offer turnkey plants with a capacity of 50 MW and more. Such a plant can produce 14,500 tons of synthetic natural gas (SNG) per year, enough fuel for 470 natural-gas-powered, local-transport buses to each cover 60,000 kilometres CO2-neutrally.

As a leading provider of reactor technology, we furthermore offer sophisticated chemical-reactor systems to convert hydrogen into a broad variety of synthetic fuels, including synthetic methane, methanol and ammonia.

Solutions for hydrogen infrastructure

A viable hydrogen infrastructure requires that hydrogen is transportable from source to point of use. This can happen via pipeline, by road in gaseous tube trailers, as well as by rail or ship. In order to transport large volumes of hydrogen, it must be pressurized and delivered as a compressed gas. This is where our turbomachinery technology comes into play with MAN’s high-tech compressor solutions being capable of installation, for instance, in future H2 pipeline compressor-stations. Additionally, MAN Energy Solutions already has expertise in building turnkey, turbomachinery systems for large industrial plants that produce ammonia and methanol, both of which viable carriers for hydrogen.

The future is here

At MAN Energy Solutions, we are helping to shape the sustainability agenda and provide a clear path for you to achieve your goals. That’s why we believe in a broad field of application for H2 and synthetic fuels – whether applied to power-and-heat generation, shipping, steel or cement production, or other industries. No matter what vessel or plant you operate, our proven, fuel-flexible engines and solutions are future-proof and ready for the climate-neutral fuels of the future.

We cover all processing steps of the hydrogen economy under the umbrella of MAN Energy Solutions.

Latest news on hydrogen topics

Study Shows Competitive Green-Hydrogen Production Possible in Northern Germany

MAN Energy Solutions and the Fraunhofer Institute for Surface Engineering and Thin Films (IST) have published their analysis of the framework conditions for the future supply of green hydrogen to the Salzgitter steel site near Hannover. Commissioned by Hydrogen Campus Salzgitter, the study investigates, among other questions, the role locally produced green hydrogen could play to support German supply and its potential competitiveness with imports.

The study’s calculations show that – if used directly without further conversion – local hydrogen can be economical and even cheaper than imports from 2030 onwards. While production costs of around 4.00 euros per kilogram are possible in northern Germany, hydrogen imported from Tunisia, for example, would cost at least 4.70 euros to produce – profit margins in both cases not included.

Marc Grünewald, Head of Business Development, Power and New Energies at MAN Energy Solutions, said: "In the case of direct use, local hydrogen has an economic advantage due to the elimination of transport and conversion costs. As such, green hydrogen can be produced in northern Germany at competitive prices and form the basis for a German hydrogen initiative – this is good news for German industry."

For the study, the authors modelled different supply chains for green hydrogen and compared possible import routes, such as those from Portugal, Canada, Tunisia and Australia. Although green hydrogen can be produced much more cheaply in countries with significant amounts of sunshine, it must then be converted for transport to Germany and subsequently back again for domestic use. This process step, which is fraught with costs and losses, drives the total expense above the cost price of H2 produced from wind energy in northern Germany, which can be transported by pipeline to its destination for immediate use.

Grünewald added: "Of course, we will still need imported hydrogen, and in large quantities, for two reasons. Firstly, due to the limited wind-energy potential in Germany, we can only cover a fraction of the prospective demand from domestic sources. Secondly, the local cost-advantage disappears the moment the hydrogen is not for direct use but rather as a raw material for synthetic fuels such as ammonia, methanol or methane. This will be the case in many instances, as for example in the shipbuilding or aviation industries. Accordingly, in addition to domestic production, we also need strong, international partners and import routes from the sunny or windy regions of North Africa, Patagonia, Scotland and Canada."

Due to its low energy-density and high volatility, pure hydrogen cannot yet be transported economically over longer distances, while ports possess neither tanker fleets nor appropriate infrastructure. Experts therefore assume that international transport will initially scale up via conversion to more conveniently transportable media, such as methanol, ammonia, etc.

Due to low technological maturity and lack of infrastructure, the study by MAN Energy Solutions and IST did not consider liquefied hydrogen or so-called LOHCs (Liquid Organic Hydrogen Carriers) in its analysis.

"These technologies may play a role after 2030 but it’s too early to tell," Grünewald said. Converting hydrogen into ammonia, methane or methanol, however, would quickly entertain large-scale import scenarios. "The world needs a massive amount of industrially-scaled, green hydrogen production. This study shows that Germany can also play an important part in building this supply."

Study only available in German Language. Please find the link here: Hydrogen Study

Documents

-

MAN ES_PM_Studie_Salzgitter_EN

Contact

Jan Hoppe

Head of Group Communication & Marketing

Group Communications & MarketingMAN Energy Solutions SEStadtbachstr. 186153 AugsburgGermany

Jan.Hoppe@man-es.com t +49 821 322 3126Available languages

- DE ·

- EN

Get notified about press releases

Related articles

-

Designing the engines of the future

The time is ripe for the sustainable engine solutions of the future. Here’s how MAN engineers are developing engines running on green fuels.

-

Sun and wind in Africa are the new oil

Why tapping Africa’s vast renewable energy resources would be an economic boom for the continent.

-

Here comes the green hydrogen boom?

The International Energy Agency’s Timur Gül on e-fuels and how we’ll bring them to scale.

-

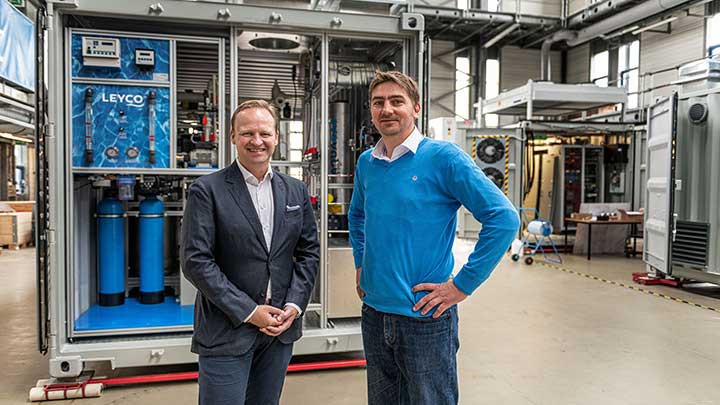

The art of green hydrogen

For decades this company has been perfecting the tech that turns renewables into green hydrogen.

-

Making fuel from sunlight and air

This mini-refinery above the rooftops in Zurich captures carbon and solar power to create clean fuel.

-

Energy transition – concrete steps to combat climate change

Which future fuel solutions do we need to reach our climate goals? VDMA expert Matthias Zelinger on solutions towards global decarbonization.

-

Power-to-X

Power-to-X is the carbon-neutral energy storage and sector coupling technology of the future: Our actions within this decade will decide whether we are able to reach the ambitious goals of the Paris agreement.