From Deggendorf to the world: reactors, apparatus, and sustainable technologies

Reactors are, essentially, about the chemical and physical transformation of matter. More specifically, reactors synthesize or process chemicals. We engineer and manufacture reactors for the chemical industry and to support decarbonization technologies. We also design and produce the apparatus and components needed by the petrochemical sector and physical research facilities.

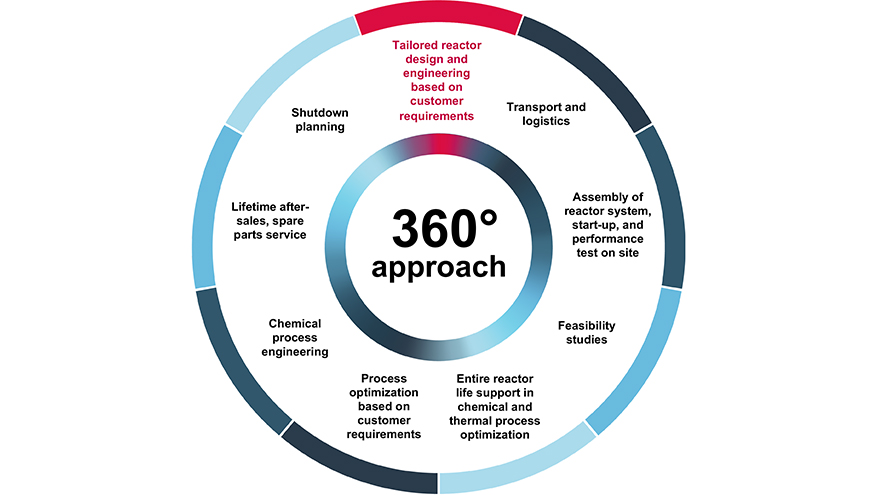

All-round reactor services

from a single source

From feasibility studies to successful turnarounds, we offer a full-service approach. Our customers benefit from individually tailored reactor design and engineering based on your specific requirements. We support you over the entire product life with chemical and thermal process optimization, maintenance, and even shutdown planning.

Sustainable energy

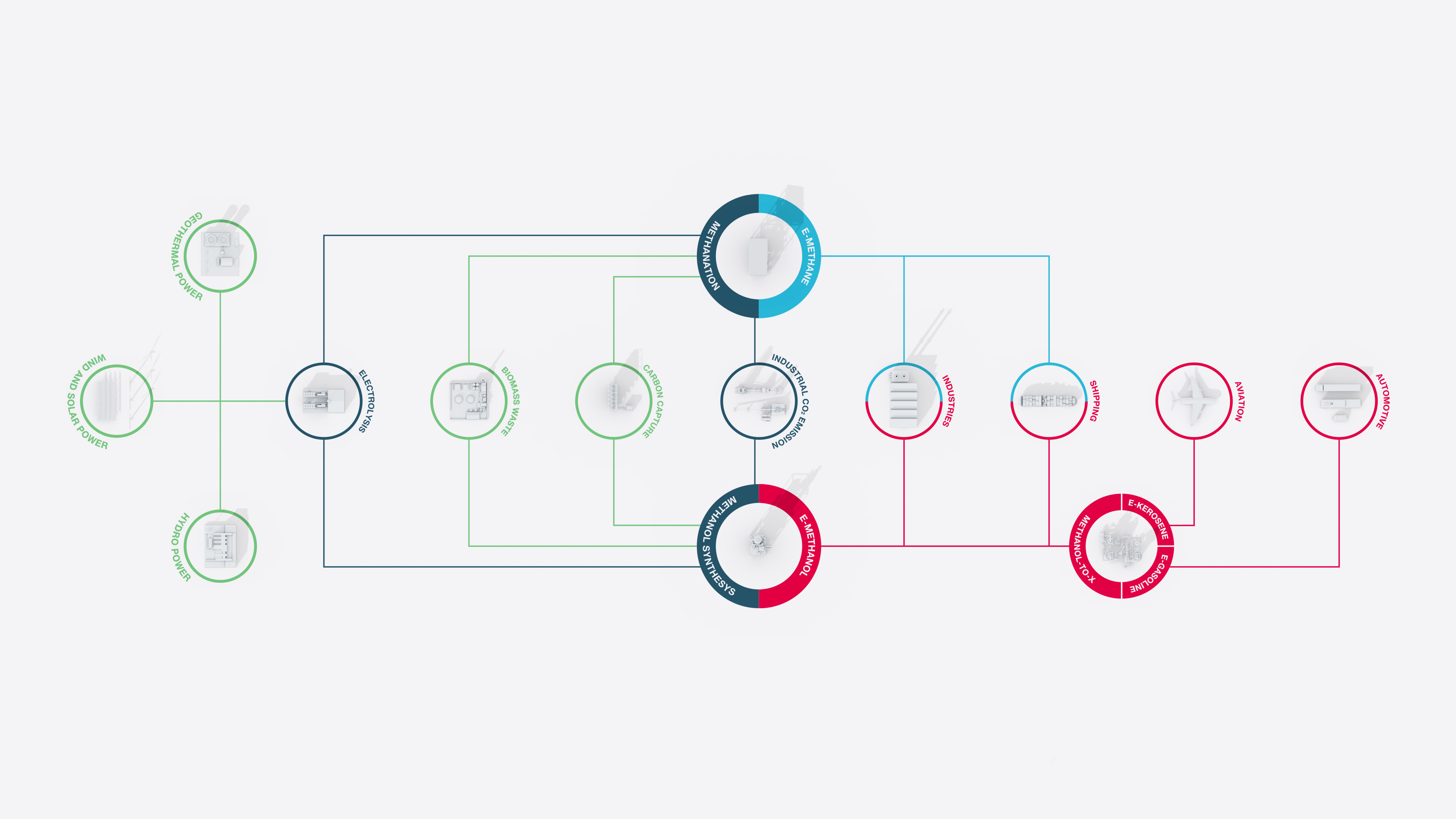

By using electricity from renewable sources, power-to-X makes CO2-neutral energy available beyond the electricity grids.

Power-to-X: producing green fuels and chemicals

MAN DWE® provides the key components for power-to-X plants. In the power-to-X process, first electricity is used to split water into hydrogen and oxygen, then carbon dioxide is added to the hydrogen in a methanation reactor, resulting in synthetic methane. Our reactors are also used to convert hydrogen into a carbon-neutral liquid fuel such as methanol, and to refine methanol into gasoline or kerosene. At MAN Energy Solutions we cover the entire value chain, producing hydrogen, converting it into other fuels and making the engines that run on those fuels.

Solutions for the chemical and petrochemical sectors

We engineer reactors for the chemical industry and apparatuses for the petrochemical industry.

Decades

of experience and the know-how of our highly-qualified employees

give us a leading position in the world market for these applications.

Chemical industry

Resilient, reliable, and efficient

MAN DWE reactors are used to make compounds such as phthalic and maleic anhydride, methyl methacrylate, acrylic acid, and acrolein. Our tubular reactors are manufactured in a complex production process using high-grade materials such as carbon steel or vanadium-reinforced chrome steel. Special cladding made from materials such as zirconium add to the longevity and safety of the reactors. We offer salt-operated and water-/oil-/gas-cooled reactors incorporating up to 60,000 tubes, up to 10 meters in diameter and 1,800 tonnes in weight.

Learn more

Petrochemical industry

For modern, efficient operations

We supply key components for virtually every application in the petrochemical industry and in refineries. Our turnaround (TAR) and shutdown engineering capabilities have been proven all over the world. We provide residue fluid catalytic cracking (RFCC) and fluid catalytic cracking (FCC) units. These comprise reactor and regenerator, pipework, pressure-retaining spare parts, internals such as combustor risers and other components such as orifice chambers.Learn more

High-quality reactor solutions

Chemical reactors

High-pressure vessels

We supply hydrocrackers, high-density polyethylene (HDPE) reactors and other specialist vessels made from high-grade materials. Our high-pressure vessels weigh up to 1,800 tonnes and feature weld overlays or are made from special materials with a wall thickness of up to 350 mm. Benefit from our experience and expertise for turnarounds or new installations.

We can design custom pressure equipment and work with special materials such as duplex, nickel-based alloys, zirconium, and high-temperature chromium steel.

RFCC/FCC components

Custom solutions

The production of some chemicals calls for special materials and conditions. We work closely with our customers to create special reactors. Sometimes, specially secured reactors with a containment design are needed for health and safety reasons. We also develop pilot plants for new processes. Testing out new ideas is expensive and can be risky. We are specialized in designing reactors which are optimized for your requirements, making the process as safe, efficient, and cost-effective as it can be.

Learn more about special reactorsContact our experts

Let's talk about chemicals

History of Deggendorf site

Career and training offers

How to find us

MAN Energy Solutions Deggendorf

Werftstraße 17,

94469 Deggendorf

t +49991 3810

Explore more topics

MAN Energy Solutions is now Everllence.

We have adopted a new brand name and moved to a new domain: www.everllence.com. This page will also be relocated there shortly. We are working on shifting all pages to www.everllence.com.