We power decarbonization

With our products and services, we operate right where the major drivers of economic and ecological progress are located. We are aware of this responsibility and are therefore already offering system technologies that help our customers increase the efficiency of their plants and applications, and reduce emissions.

However, we focus on tomorrow by investing in promising technologies like Battery Hybrid, Green Hydrogen, Power-to-X or Energy Storage.

Low carbon marine solutions

Half the world´s shipping sails under the power of MAN Energy Solutions and each step we take to make our engines more efficient can have a measurable effect on the environment and our customer’s bottom line.

We believe that the future belongs to synthetic fuels generated from renewable energy sources. On this road, LNG is not the end goal, but an investment in the future as all such engines can run on carbon-free fuels without further technical adaptions.

However, the Maritime Energy Transition requires more than just one solution. To this end, we offer MAN ECO CONTROL, a portfolio of technologies that help our marine customers to optimize a ship’s performance in terms of emissions, energy efficiency, economy and operation and let them benefit from smart processes, efficient operation and predictive maintenance services.

Our solutions help reduce ship's emissions, improve efficiency, utilize cleaner fuels and thus meet all current and future regulations while ensuring a lower impact on the environment.

Low carbon energy solutions

A carbon-neutral future needs renewable energies. However, the major challenge remains in their integration into existing energy systems.

This is why we at MAN Energy Solutions develop various hybrid and storage technologies for the energy systems of tomorrow.

When it comes to ensuring reliability and securing the energy supply, MAN offers unparalleled expertise and experience in power generation, combined with the right products and solutions to suit diverse energy markets.

Beyond this, novel decarbonization solutions are another part of MAN Energy Solutions’ portfolio. For example, Power-to-X or clean hybrid and ultra-efficient power plants.

Our customers benefit from the latest technologies – including our smart energy management systems, which ensure the most environmentally friendly, economical energy sources for power production.

Low carbon Oil & Gas solutions

MAN Energy Solutions offers intelligent, sustainable solutions and unique technologies for all sectors of the oil and gas industry. Our solutions are designed to reduce waste and minimize resource consumption along the entire value chain – from refinery to transport, and during the processing of these valuable resources.

For instance, our groundbreaking MAN Subsea technology is supporting the lifetime extension of Norway´s main gas field, Asagard, by another 15 years.

Moreover, MAN Energy Solutions is supplying technologies for carbon capture and storage (CSS), which is increasingly taking center stage in the industry and politics alike.

Low carbon Process Industry solutions

The manufacturing and refining sectors of the global economy are incredibly diverse. However, all industries have one thing in common: the need for sustainable, efficient and cost-effective solutions in order to reduce emissions and industrial waste.

MAN Energy Solutions offers a wide array of specialized products and solutions that cater to the specific needs of diverse industries - from paper to pipeline, from fertilizer to ferrous metals. MAN products are found in both the largest industrial plants in the world and in smaller, single-site operations.

Low carbon service solutions

As sustainability becomes a focal point for our customers’ business, so it becomes a priority for our services. Limiting waste in materials, work force and energy consumption is not just for new installations and products, it is also crucially important for maintenance, repair and retrofits.

The latest solutions for retrofits and upgrades by MAN PrimeServ ensure energy efficiency, cut greenhouse emissions, and minimize the carbon footprint of any installation. Our solutions not only help tackle efficiency challenges but offer future-proof, cost-aware options to sharpen our customers’ competitive edge.

To help meet the challenges of a transforming energy market and ever-stricter regulations, we monitor global and local market trends and regulatory and legislative requirements. To guarantee state-of-the-art service solutions from a single source, we always keep a 360° perspective on important markets, OEM expertise and third-party competence.

Latest news on decarbonization

ME-GI Engines to Power Liquid-CO2 Carriers in Groundbreaking Carbon-Transport-and-Storage Project

Dalian Shipbuilding Industry Co. Ltd. has ordered 2 × MAN B&W 7S35ME-GI dual-fuel engines in connection with the construction of two 7,500 cubic-metre, liquid CO2 carriers for Northern Lights, the joint venture between Equinor, Shell and TotalEnergies. Each ME-GI engine will feature MAN Energy Solutions’ proprietary EcoEGR (Exhaust Gas Recirculation) system. Delivery of the 130-metre carriers has been set for mid-2024.

Northern Lights is responsible for developing and operating CO2 transport and storage facilities as part of ‘Longship’, the Norwegian Government’s full-scale, carbon-capture-and-storage (CCS) project. Northern Lights will create the first ever, cross-border, open-source, CO2 transport-and-storage infrastructure network, offering European companies the opportunity to store their CO2 safely and permanently underground.

Wayne Jones OBE, Chief Sales Officer and Member of the Executive Board of MAN Energy Solutions, said: “We are delighted with our role in this groundbreaking project. With the current focus in the maritime world on reducing methane slip, our dual-fuel ME-GIs will keep carrier emissions to a minimum in this project whose green credentials will be carefully examined. These vessels’ construction enables the revolutionary development of a flexible and efficient, European infrastructure for CO2 capture from industrial customers. I am convinced that the Northern Lights project has great potential for application across Europe.”

The newbuilding carriers will be used in the first phase of Northern Lights’ transport-and-storage-infrastructure development and are designed to transport liquid CO2 in purpose-built, pressurised cargo tanks. The dual-fuel ME-GI engines will mainly run on LNG, while other innovative technologies – such as a wind-assisted propulsion system and air lubrication – will be installed to reduce carbon intensity by around 34%, compared to conventional systems. The ships are the first of their kind and have the potential to set a new standard for CO2 shipping on coastal trading routes.

The Northern Lights project allows for further phases to expand capacity through future investments triggered by market demand from large CO2 emitters across Europe.

Norcem carbon-capture project

The Norwegian Government’s Longship project aims to demonstrate that carbon-capture technology can be applied to larger industrial plants and set a new standard for future industrial projects. The HeidelbergCement Norcem plant near Oslo will be the first to use the Carbon Capture Heat Recovery technology (CCWHR®) developed by MAN and Aker Carbon Capture from the summer of 2024 when it will capture 400,000 tons of CO2 annually, corresponding to 50% of its overall emissions. The gas will be compressed, liquefied and subsequently transported by Northern Lights by use of the new carriers to their onshore receiving terminal near Bergen in western Norway, from where a pipeline will lead to an underground storage location in the North Sea.

Dr Uwe Lauber, CEO of MAN Energy Solutions, said: "CO2 emissions are currently unavoidable in cement production with the sector accounting for almost 6 - 7% of the world’s carbon-dioxide emissions. This is why the cement industry is key on the road to a decarbonised future. We are very proud to be able to deliver such an energy-efficient solution for HeidelbergCement Norcem, which is the result of our successful pioneering work in the CCS field together with Aker Carbon Capture."

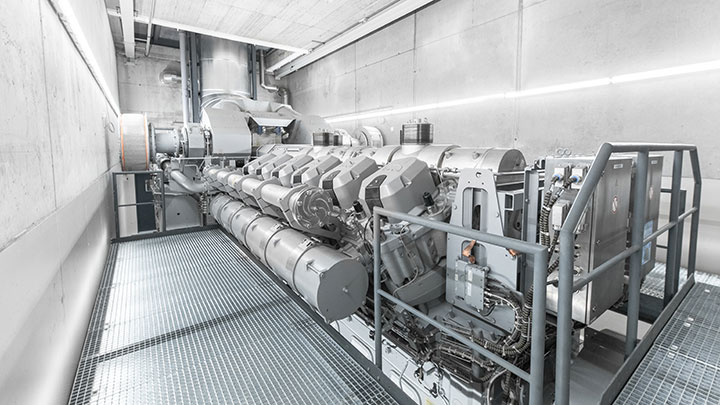

MAN Energy Solutions’ scope of supply for the cement factory includes an electrically-powered compressor train – type RG 63-7 with integrated CCWHR® technology – which allows the compression heat of the recovery compressor to be exploited. The steam generators cool the CO2 mixture between the compressor stages and generate steam that is in turn used for capture.

Documents

-

220309_MAN_ES_PR_LCO2-Carrier-Project_ENG

Contact

Nils Søholt

Trade Press Marine

Group Communications & MarktingMAN Energy SolutionsTeglholmsgade 412450 Copenhagen SVDenmark

nils.soeholt@man-es.com t +45 33 85 26 69Available languages

- DE ·

- EN

Get notified about press releases

Related articles

-

Gas engine power plant in Chemnitz

Find out how two gas engine power plants in Chemnitz, Germany, are cutting CO2 emissions by 60 percent and paving the path for a carbon-free future.

-

Methanol fueled ships

Sustainable shipping starts now. Find out more about the first large-scale engines for container ships run on green methanol.

-

Haru Oni e-fuels

The Haru Oni demonstration plant could pave the way for a viable alternative to fossil fuels: It produces synthetic e-fuels from hydrogen that can help the fight against climate change. MAN Energy Solutions provided the e-methanol reactor to the plant.

-

Esbjerg Heat Pump

How a seaport town in Denmark is decarbonizing district heating with seawater and large-scale industrial heat pumps.

-

Upgrading your fleet for future fuels

MAN Energy Solutions experts on the climate impact and business case for converting ships to dual-fuel engine operation.

-

H-TEC SYSTEMS: The hydrogen electrolyzer pioneer

Under new leadership, PEM electrolysis pioneer H-TEC SYSTEMS is scaling up electrolyzer production to meet the growing demand for green hydrogen.

-

bellona-carbon-capture-storage

Carbon Capture and Storage is one of the necessary building blocks to achieve carbon-neutral industry, says Erika Bellmann of NGO Bellona.

-

ETES heat pump

Danish utility DIN Forsyning is using an innovative solution with new ETES heat pump technology to decarbonize heating for an entire town.

-

Carbon capture utilization storage

Carbon capture, utilization and storage will become more important for the energy transition as unavoidable emissions move to the forefront of discussions.

-

Making the maritime energy transition

The work being done on carbon-neutral engines at the Research Centre Copenhagen in Denmark is crucial for the maritime energy transition.

-

The benefits of methanol

What makes methanol so attractive for the maritime energy transition? MAN Energy Solutions fuel expert Kjeld Aabo explains.

-

Designing the engines of the future

The time is ripe for the sustainable engine solutions of the future. Here’s how MAN engineers are developing engines running on green fuels.

-

Combined Heat and Power systems for the future

How combined heat and power plants support a German city to reach its target of climate-neutral power and heat generation until 2035.

-

Heating up renewable energy storage

Energy-expert Professor Manfred Wirsum on decarbonizing how we heat and cool the places where we live and work.

-

The art of sustainable production

Behind the practices making climate protection a fundamental part of our manufacturing.

-

LPG makes waves in green shipping

Pontus Berg of BW LPG talks about retrofitting vessels with greener dual-fuel LPG engines.

-

What the future holds for shipping

Can shipping halve emissions by 2050? We look at four scenarios with four very different outcomes.

-

The case for two-stroke ammonia engines

Why newbuild and retrofit ammonia engines are key for the maritime energy transition.

-

The art of green hydrogen

For decades this company has been perfecting the tech that turns renewables into green hydrogen.

-

When cars cross oceans

200 meters long and 13 car decks high these new mammoth car carriers run on LNG.

-

Shining a light on a smart island

How the remote Faroe Islands are using a microgrid to become 100 percent green in the next decade.

-

Making fuel from sunlight and air

This mini-refinery above the rooftops in Zurich captures carbon and solar power to create clean fuel.

-

Climate-friendly engines go fishing

The first LNG-powered fishing trawler nets industry attention for its big emission reductions.

-

Cleaner energy for Rock of Gibraltar

When Gibraltar upgraded its nearly 40-year-old power system, they opted for a unique LNG solution.

-

Designs for a livable future

Giant kites and smog-sucking towers: Can socially-oriented designs create a more sustainable world?

-

Automated subsea platform for deepwater compression

The world’s first subsea compression system has revolutionized oil exploration; learn how automation and digitalization make it cleaner and more efficient.

-

Energy transition – concrete steps to combat climate change

Which future fuel solutions do we need to reach our climate goals? VDMA expert Matthias Zelinger on solutions towards global decarbonization.

-

Innovation inspired by nature

By learning from and emulating nature’s solutions, biomimicry can help solve complex human design and engineering problems.

-

Combined Heat and Power

A new combined heat and power (CHP) plant delivers a flexible and efficient energy solution that saves up to 60,000 metric tons of CO2 per year.

-

Power-to-X

Power-to-X is the carbon-neutral energy storage and sector coupling technology of the future: Our actions within this decade will decide whether we are able to reach the ambitious goals of the Paris agreement.

-

-

Setting sail for a sustainable future

The IMO sets targets for decarbonization. Here’s how marine shipping can help achieve climate goals.

-

A tale of fire and ice

Inside the electro-thermal energy storage solution that will green the heating and cooling sector.

-

World’s largest fusion reactor

In southern France, a cast of thousands is working to change the future of sustainable energy.

-

A roadmap to the green zone

The first container ship converted to LNG offers real insight into making the industry carbon-neutral.